2 月 . 15, 2025 22:53 Back to list

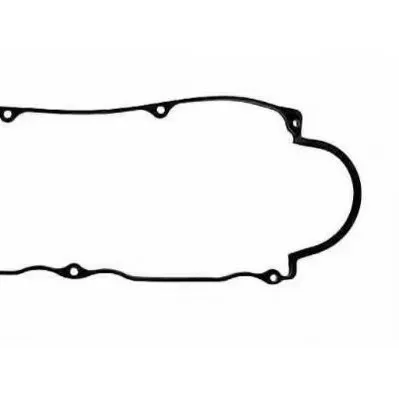

20x30x7 oil seal

Selecting the appropriate oil seal for machinery is crucial to ensuring optimal performance and longevity. Among various specifications, the 20x30x7 oil seal stands out due to its versatile dimensions and reliability in various applications. With expanding industrial demands, understanding the characteristics and use-cases of such oil seals can significantly enhance machinery efficiency.

Real-world application and feedback demonstrate a high level of satisfaction among engineers and technicians. The common consensus highlights the 20x30x7 oil seal's robustness and adaptability in various settings as indispensable. For industries where downtime translates to significant financial loss, the reliability of these oil seals is not merely a preference but a necessity. The importance of choosing a quality oil seal brand cannot be overstated. Reputed manufacturers ensure rigorous testing and adherence to stringent standards, which translate into longer service intervals and cost savings over time. Verifying the authenticity of the oil seals through careful supplier selection protects against counterfeit products that could compromise system integrity. Investing in high-quality oil seals like the 20x30x7 model equips machinery with a pivotal component that guards against inefficiencies and system failures. Expertise in selecting the appropriate seal requires a nuanced understanding of the operating conditions—temperatures, pressures, and fluids involved. For professionals tasked with maintaining the seamless operation of machinery, integrating trusted seals into their maintenance regimen establishes not only operational efficiency but also elevates the trust and reputation within the industry. Therefore, the 20x30x7 oil seal is more than a part of the machinery; it is an assurance of performance, longevity, and reliability. The dedication towards continuous improvement in seal technology speaks to the dynamic advancements within industrial sectors, striving for components that not only meet but exceed operational expectations. This seal cross-cuts various industries and applications, proving its indispensability in a competitive manufacturing landscape.

Real-world application and feedback demonstrate a high level of satisfaction among engineers and technicians. The common consensus highlights the 20x30x7 oil seal's robustness and adaptability in various settings as indispensable. For industries where downtime translates to significant financial loss, the reliability of these oil seals is not merely a preference but a necessity. The importance of choosing a quality oil seal brand cannot be overstated. Reputed manufacturers ensure rigorous testing and adherence to stringent standards, which translate into longer service intervals and cost savings over time. Verifying the authenticity of the oil seals through careful supplier selection protects against counterfeit products that could compromise system integrity. Investing in high-quality oil seals like the 20x30x7 model equips machinery with a pivotal component that guards against inefficiencies and system failures. Expertise in selecting the appropriate seal requires a nuanced understanding of the operating conditions—temperatures, pressures, and fluids involved. For professionals tasked with maintaining the seamless operation of machinery, integrating trusted seals into their maintenance regimen establishes not only operational efficiency but also elevates the trust and reputation within the industry. Therefore, the 20x30x7 oil seal is more than a part of the machinery; it is an assurance of performance, longevity, and reliability. The dedication towards continuous improvement in seal technology speaks to the dynamic advancements within industrial sectors, striving for components that not only meet but exceed operational expectations. This seal cross-cuts various industries and applications, proving its indispensability in a competitive manufacturing landscape.

Next: