8 月 . 28, 2024 14:57 Back to list

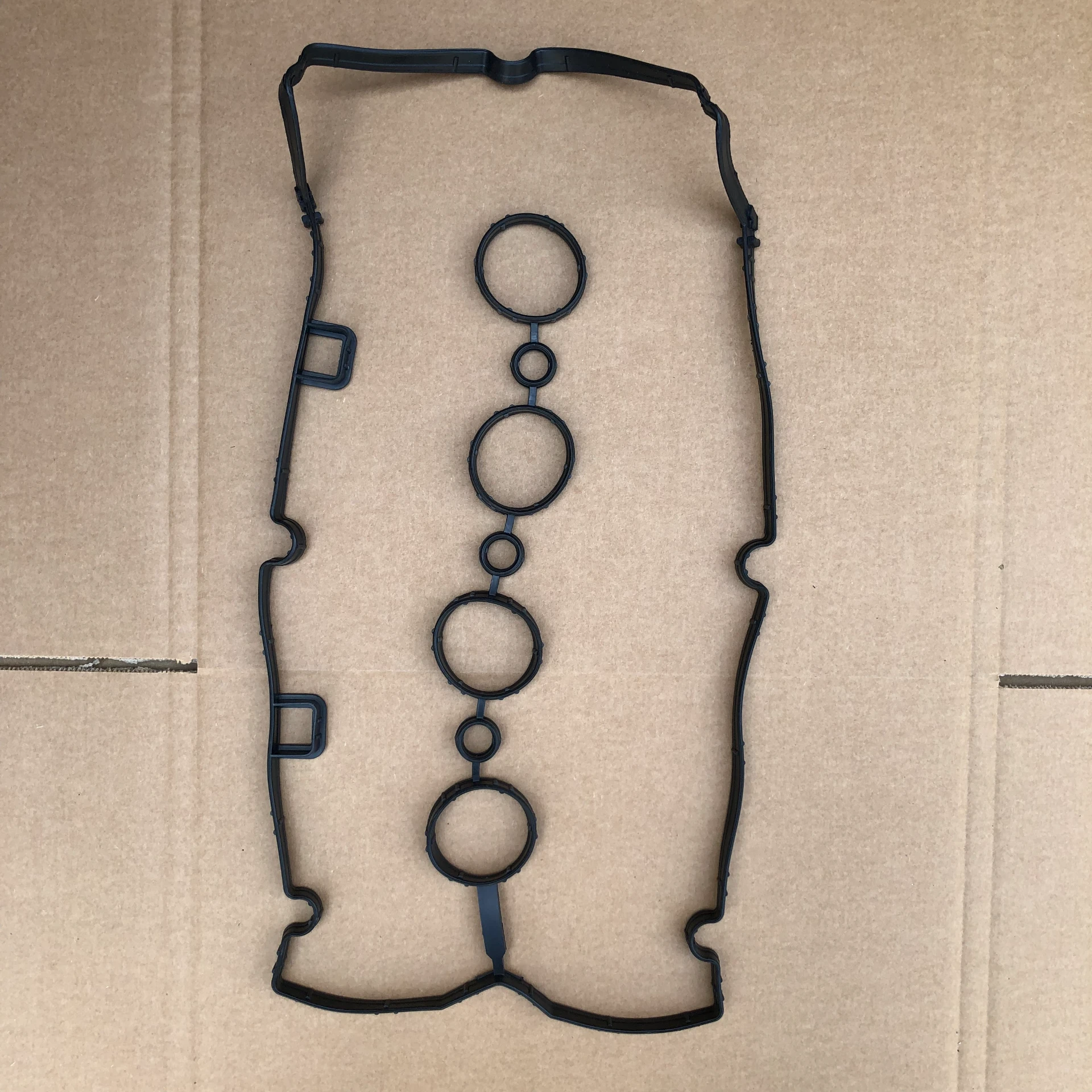

22 35 7 oil seal

The Importance of the 22% 35% 7% Oil Seal in Industrial Applications

In the world of industrial mechanics, oil seals play a critical role in ensuring the efficiency and longevity of machinery. One particularly notable classification of oil seals is the 22% 35% 7% oil seal, which signifies specific dimensions and specifications tailored for diverse applications. Understanding the significance and functionality of this oil seal can greatly benefit industries such as automotive, manufacturing, and aerospace.

The Importance of the 22% 35% 7% Oil Seal in Industrial Applications

One of the primary functions of the 22% 35% 7% oil seal is to maintain lubricant integrity within machinery. Oil seals are designed to keep lubricants contained within specific compartments, ensuring that moving parts are adequately lubricated. This lubrication minimizes friction, which can lead to wear and tear on machinery. Consequently, a reliable seal contributes to reduced maintenance costs and extends the overall life of industrial equipment.

22 35 7 oil seal

Moreover, oil seals are essential in preventing contaminants such as dirt, dust, and moisture from entering sensitive machinery components. The presence of these foreign particles can severely affect the performance of the equipment, leading to potential failures that could halt production. Hence, integrating a 22% 35% 7% oil seal into machinery helps ensure that only the right substances interact with crucial components, thus preserving their functionality.

Industries utilizing the 22% 35% 7% oil seal span across various sectors. In the automotive industry, for example, these seals are commonly found in engines, transmissions, and wheel bearings, where they support optimal performance and safety. Similarly, manufacturing applications often require these seals to protect gearboxes and hydraulic systems, thus ensuring a smooth operation.

In conclusion, the 22% 35% 7% oil seal is not just a minor component but rather a vital element in achieving operational efficiency across numerous industrial applications. By understanding its specifications and functions, industries can better appreciate how these oil seals contribute to machinery longevity and performance. Investing in quality oil seals can lead to significant long-term benefits, ultimately enhancing productivity and reducing downtime.