1 月 . 21, 2025 02:38 Back to list

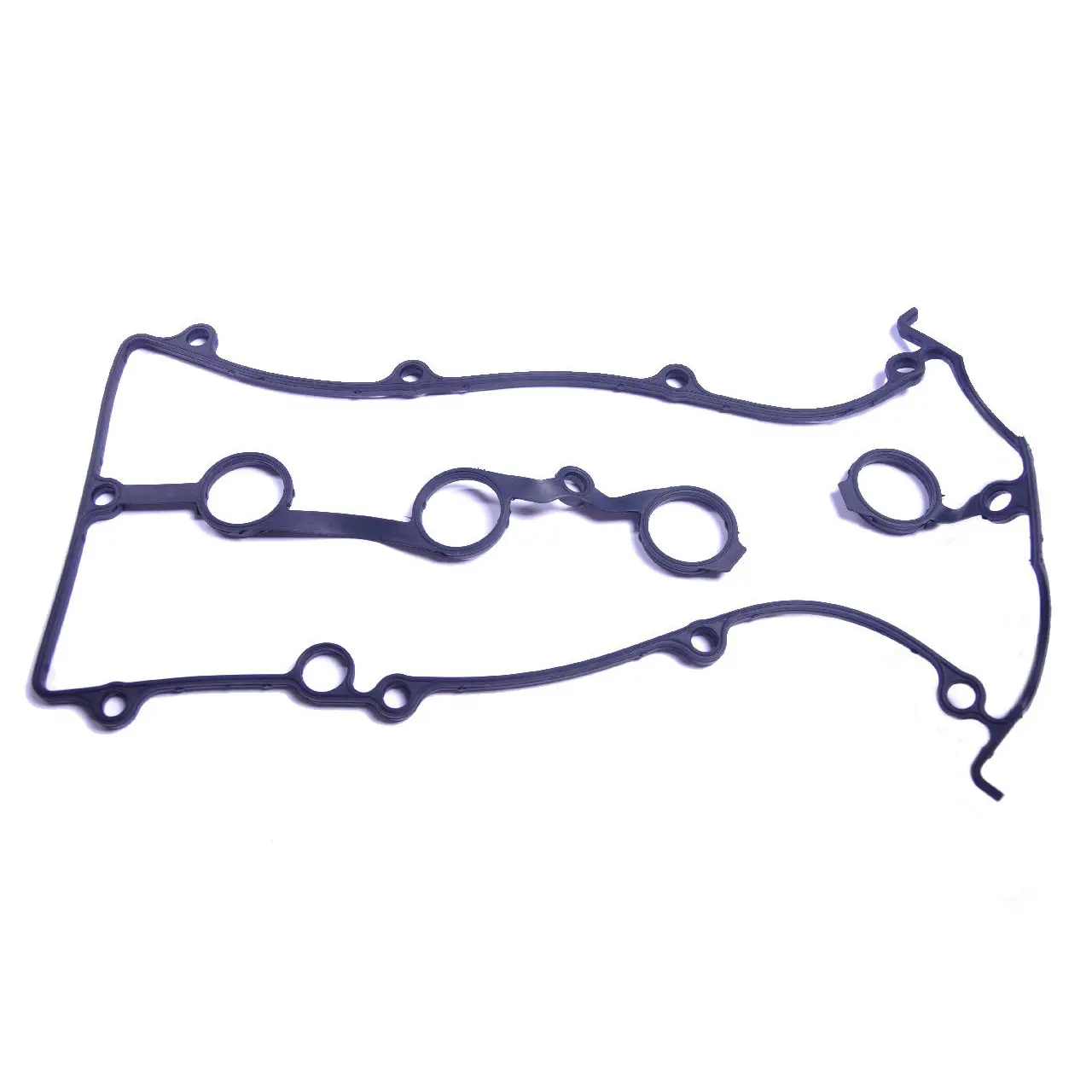

22 40 7 oil seal

In the realm of industrial machinery and automotive applications, the term 22 40 7 oil seal might appear rather technical, yet it holds significant importance among key components that ensure the smooth operation of mechanical systems. This specific size designation 22x40x7 indicates the inner diameter, outer diameter, and width of the oil seal in millimeters, offering precision in its application across various mechanical systems. These oil seals, also known as shaft seals, play a crucial role in maintaining the integrity of lubricants, preventing contamination, and ensuring a long lifespan for machinery.

In terms of authority and trustworthiness, manufacturers who have garnered a robust reputation in the production of oil seals offer certifications and warranties affirming the quality and durability of their products. Choosing a manufacturer with a proven track record in producing reliable and efficient oil seals, such as the 22 40 7 oil seal, should be prioritized. A trusted manufacturer will typically adopt stringent quality control measures during production, ensuring that the oil seals meet or exceed industry standards. The evolution of technology also plays a pivotal role in the advancement of oil seal designs. With sophisticated simulations and testing methodologies, today's engineers can predict the performance of oil seals more accurately than ever before. This technological integration ensures that each 22 40 7 oil seal is tailored to meet the specific demands of modern machinery, providing peace of mind to operators and engineers alike. Innovation in the field continues to surge with the development of environmentally friendly materials for oil seals, aligning with global sustainability objectives. These advancements are crucial not only for environmental compliance but also for innovation in extending the functional lifespan of machinery without compromising on performance. In conclusion, the importance of selecting and maintaining quality oil seals like the 22 40 7 cannot be overstated. With their pivotal role in operational efficiency, longevity, and cost-effectiveness of machinery, these components are a testament to the marriage of material science, engineering expertise, and technological innovation. By focusing on the integration of quality components, rigorous maintenance practices, and reliance on credible manufacturers, industries can achieve seamless mechanical performance and robust operational outputs.

In terms of authority and trustworthiness, manufacturers who have garnered a robust reputation in the production of oil seals offer certifications and warranties affirming the quality and durability of their products. Choosing a manufacturer with a proven track record in producing reliable and efficient oil seals, such as the 22 40 7 oil seal, should be prioritized. A trusted manufacturer will typically adopt stringent quality control measures during production, ensuring that the oil seals meet or exceed industry standards. The evolution of technology also plays a pivotal role in the advancement of oil seal designs. With sophisticated simulations and testing methodologies, today's engineers can predict the performance of oil seals more accurately than ever before. This technological integration ensures that each 22 40 7 oil seal is tailored to meet the specific demands of modern machinery, providing peace of mind to operators and engineers alike. Innovation in the field continues to surge with the development of environmentally friendly materials for oil seals, aligning with global sustainability objectives. These advancements are crucial not only for environmental compliance but also for innovation in extending the functional lifespan of machinery without compromising on performance. In conclusion, the importance of selecting and maintaining quality oil seals like the 22 40 7 cannot be overstated. With their pivotal role in operational efficiency, longevity, and cost-effectiveness of machinery, these components are a testament to the marriage of material science, engineering expertise, and technological innovation. By focusing on the integration of quality components, rigorous maintenance practices, and reliance on credible manufacturers, industries can achieve seamless mechanical performance and robust operational outputs.

Next: