1 月 . 21, 2025 00:33 Back to list

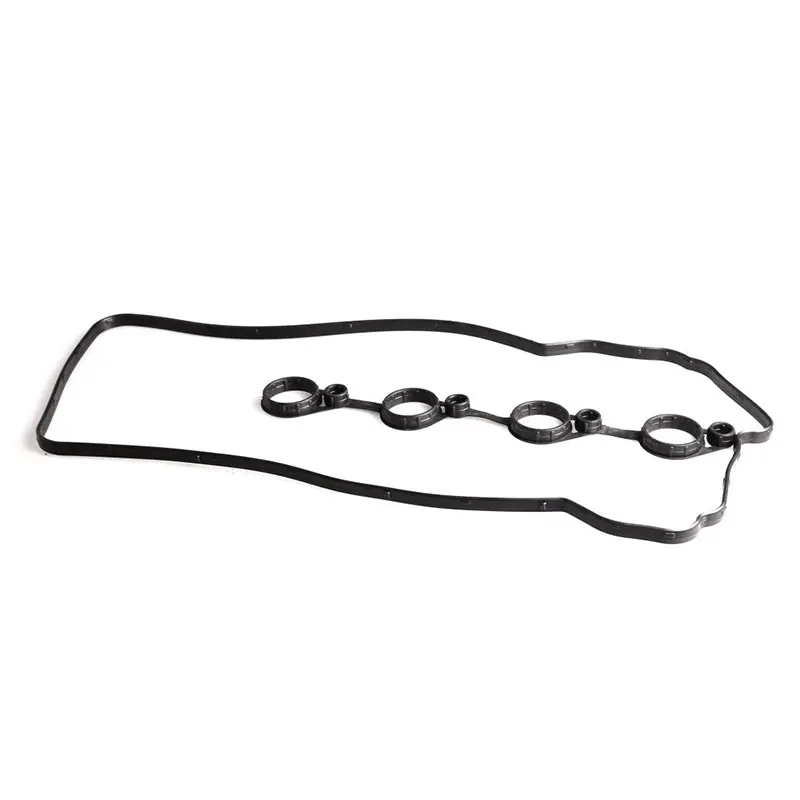

25x40x7 oil seal

In the world of machinery and automotive maintenance, the 25x40x7 oil seal stands out as an essential component, integral to the efficiency, longevity, and seamless operation of mechanical systems. This seal addresses critical needs in equipment ranging from automotive engines to industrial machinery, affirming its position as indispensable in the industry.

Trustworthiness emerges from rigorous testing and proven performance data of these seals in real-world applications. Experts in mechanical maintenance and engineering often conduct comprehensive assessments, analyzing factors such as longevity under load, resistance to chemical exposure, and performance consistency over time. The findings from these tests, coupled with feedback from a global network of technicians and engineers, underscore the 25x40x7 oil seal's reliability. The installation process for these seals also contributes to their effectiveness and lifespan. Ensuring proper installation requires meticulous attention to detail; misalignment can lead to premature wear or even complete seal failure. Utilizing specialized tools and following precise protocols during installation is recommended to mitigate potential issues and maximize the seal's lifespan. Furthermore, maintaining ongoing inspections and timely replacements forms part of a robust machine maintenance regimen. Regular monitoring for signs of wear, leakage, or degradation ensures that the seals function optimally, safeguarding the machinery’s internal components. In conclusion, the 25x40x7 oil seal serves as a cornerstone in maintaining operational integrity and extending the lifespan of various machines. By choosing high-quality seals, understanding the specific materials and appropriate applications, and adhering to expert installation and maintenance practices, one can enhance mechanical reliability and tackle challenges with confidence. The integration of such components into mechanical systems not only showcases a commitment to quality but also reflects adherence to best practices within the industry.

Trustworthiness emerges from rigorous testing and proven performance data of these seals in real-world applications. Experts in mechanical maintenance and engineering often conduct comprehensive assessments, analyzing factors such as longevity under load, resistance to chemical exposure, and performance consistency over time. The findings from these tests, coupled with feedback from a global network of technicians and engineers, underscore the 25x40x7 oil seal's reliability. The installation process for these seals also contributes to their effectiveness and lifespan. Ensuring proper installation requires meticulous attention to detail; misalignment can lead to premature wear or even complete seal failure. Utilizing specialized tools and following precise protocols during installation is recommended to mitigate potential issues and maximize the seal's lifespan. Furthermore, maintaining ongoing inspections and timely replacements forms part of a robust machine maintenance regimen. Regular monitoring for signs of wear, leakage, or degradation ensures that the seals function optimally, safeguarding the machinery’s internal components. In conclusion, the 25x40x7 oil seal serves as a cornerstone in maintaining operational integrity and extending the lifespan of various machines. By choosing high-quality seals, understanding the specific materials and appropriate applications, and adhering to expert installation and maintenance practices, one can enhance mechanical reliability and tackle challenges with confidence. The integration of such components into mechanical systems not only showcases a commitment to quality but also reflects adherence to best practices within the industry.

Next: