10 月 . 12, 2024 03:34 Back to list

35x52x7 oil seal

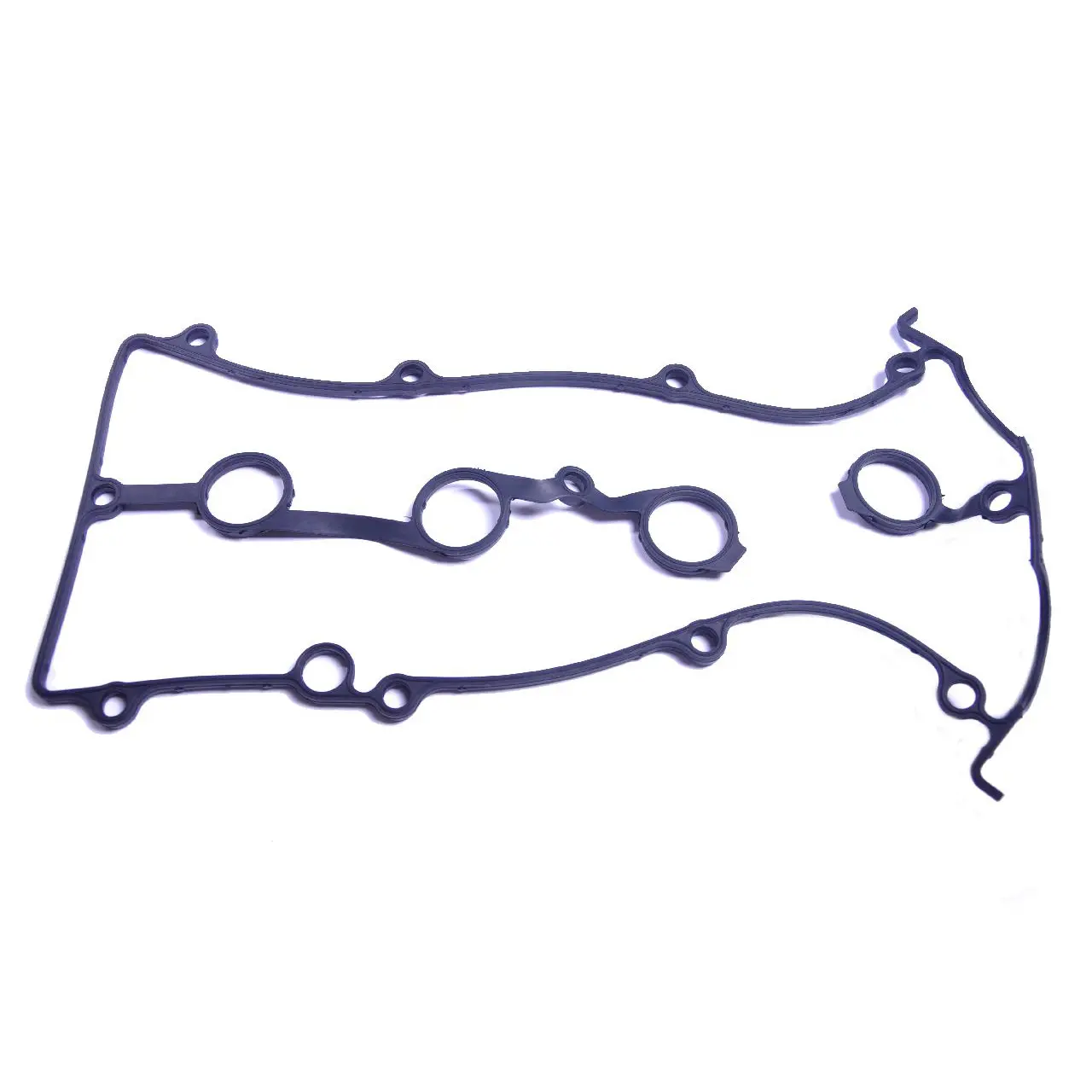

Understanding the 35x52x7 Oil Seal A Detailed Overview

The 35x52x7 oil seal is a crucial component in various machinery and automotive applications, serving a vital role in preventing fluid leakage and ensuring the efficient operation of mechanical systems. Understanding the specifications, applications, and importance of this oil seal helps in appreciating its value in engineering and maintenance.

What is an Oil Seal?

An oil seal, often referred to as a shaft seal or a radial oil seal, is a mechanical device designed to retain lubricants within a machinery system while preventing the ingress of contaminants. Oil seals are typically made from elastomers or rubber compounds and are molded into various shapes to fit around shafts or components. They work by creating a dynamic and static seal, effectively blocking any unwanted leakage of oil, grease, or other fluids.

Specifications of the 35x52x7 Oil Seal

The designation 35x52x7 refers to the dimensions of the oil seal

- 35 mm The inner diameter (ID) of the seal, which specifies the size of the shaft it fits onto. - 52 mm The outer diameter (OD) of the seal, indicating the area where the seal will be installed in a housing or bore. - 7 mm The thickness (or width) of the seal, which affects the depth of the groove that must be machined into the housing.

These dimensions make the 35x52x7 oil seal suitable for a variety of applications, particularly in rotating machinery where oil retention is critical.

Applications of the 35x52x7 Oil Seal

The 35x52x7 oil seal finds applications in numerous industries

1. Automotive In vehicles, oil seals are primarily employed in engine components, such as crankshafts and camshafts, to retain engine oil while preventing contaminants like dust and dirt from entering.

2. Industrial Machinery In manufacturing equipment, oil seals are employed in gearboxes, pumps, and motors to ensure proper lubrication of moving parts, which helps in reducing friction and wear.

3. Agricultural Equipment Farming machinery, such as tractors and harvesters, often incorporate oil seals to protect hydraulic systems and transmission fluids from leaks and external contamination.

35x52x7 oil seal

4. Home Appliances Even in everyday appliances like washing machines and dishwashers, oil seals play a crucial role in maintaining fluid integrity in motors and gear assemblies.

Importance of Choosing the Right Oil Seal

Selecting the appropriate oil seal, such as the 35x52x7, is vital for several reasons

- Preventing Leakage An effective oil seal reduces the risk of oil leaking from a system, which can lead to increased maintenance costs and reduced efficiency. - Extending Equipment Life Properly functioning seals protect against contaminants that could cause significant wear on machinery parts, thereby extending the overall lifespan of the equipment.

- Maintaining Performance A good seal ensures that machinery operates within its designed parameters, thereby helping maintain optimal performance levels.

Factors Influencing Oil Seal Performance

Several factors can affect the performance and lifespan of an oil seal

1. Material Composition The type of rubber or elastomer used in manufacturing the seal significantly influences its resistance to heat, pressure, and chemical exposure. Common materials include Nitrile Rubber (NBR), Fluoroelastomer (FKM), and Ethylene Propylene Diene Monomer (EPDM).

2. Operating Conditions The temperature, pressure, and surrounding environment in which the seal operates can drastically impact its durability. It is essential to consider these conditions when selecting an oil seal for specific applications.

3. Installation Practices Proper installation is crucial for the effective performance of an oil seal. Incorrect installation can lead to premature failure, which can result in costly repairs.

Conclusion

The 35x52x7 oil seal is more than just a small rubber component; it is a fundamental element in ensuring the operational efficiency of a wide range of mechanical systems. By preventing leaks and protecting against contaminants, this oil seal contributes to the longevity and performance of machinery across various industries. Understanding its specifications, applications, and importance underscores the need for careful selection and maintenance of oil seals in any mechanical system. When properly selected and installed, the 35x52x7 oil seal can prove to be an invaluable asset in both industrial and automotive applications.