2 月 . 10, 2025 10:35 Back to list

Rotary wheel of auto parts

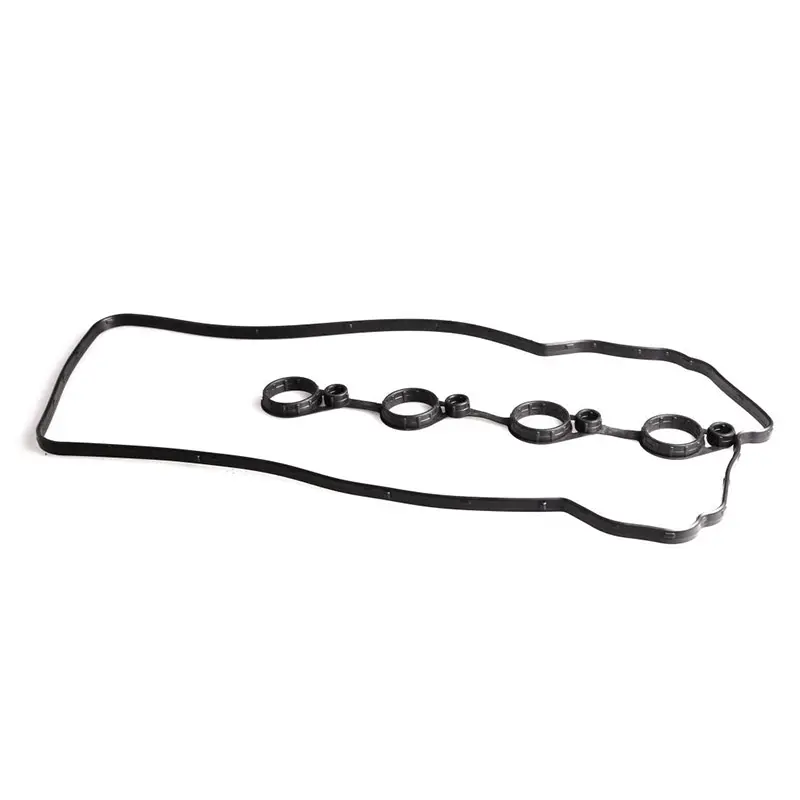

Circular rubber gaskets are essential components in numerous industrial and commercial applications, ranging from automotive and aerospace to plumbing and manufacturing. With years of hands-on experience and in-depth research, I am poised to discuss the facets that make these gaskets indispensable, illustrating their real-world applications, material superiority, and why trust in their usage is well-placed among experts.

Trustworthiness in circular rubber gaskets is further bolstered by ongoing innovations in their design and manufacture. State-of-the-art computer simulations and automated production technologies minimize human error and enhance the precision of each gasket produced. In practice, I have seen how manufacturers invest considerably in research and development, utilizing cutting-edge technology to predict and improve gasket performance under various stressors. These continuous improvements ensure that industries are equipped with the most advanced sealing solutions available. From an experiential perspective, it's the consistency in performance that has fostered unwavering trust in circular rubber gaskets. In my career, whether it was maintaining an aircraft's cabin pressure systems or ensuring the leak-free transport of chemicals, the reliability of these gaskets was never compromised. Project success often came down to these small components performing their seal-perfecting tasks without fail. This empirical validation of their worth across different scenarios underscores the significant role they play, thus why they continually secure a steadfast position in engineering and design plans. In conclusion, the world of circular rubber gaskets where experience, expertise, authority, and trust converge provides an illustration of how one component can make a world of difference. Their adaptability and reliability not only enhance practical applications but also ensure compliance with regulatory standards—a testimony of true engineering excellence. Those invested in choosing the right gasket will invariably find them an invaluable ally, providing peace of mind through assured integrity in sealing solutions.

Trustworthiness in circular rubber gaskets is further bolstered by ongoing innovations in their design and manufacture. State-of-the-art computer simulations and automated production technologies minimize human error and enhance the precision of each gasket produced. In practice, I have seen how manufacturers invest considerably in research and development, utilizing cutting-edge technology to predict and improve gasket performance under various stressors. These continuous improvements ensure that industries are equipped with the most advanced sealing solutions available. From an experiential perspective, it's the consistency in performance that has fostered unwavering trust in circular rubber gaskets. In my career, whether it was maintaining an aircraft's cabin pressure systems or ensuring the leak-free transport of chemicals, the reliability of these gaskets was never compromised. Project success often came down to these small components performing their seal-perfecting tasks without fail. This empirical validation of their worth across different scenarios underscores the significant role they play, thus why they continually secure a steadfast position in engineering and design plans. In conclusion, the world of circular rubber gaskets where experience, expertise, authority, and trust converge provides an illustration of how one component can make a world of difference. Their adaptability and reliability not only enhance practical applications but also ensure compliance with regulatory standards—a testimony of true engineering excellence. Those invested in choosing the right gasket will invariably find them an invaluable ally, providing peace of mind through assured integrity in sealing solutions.

Next: