10 月 . 15, 2024 16:39 Back to list

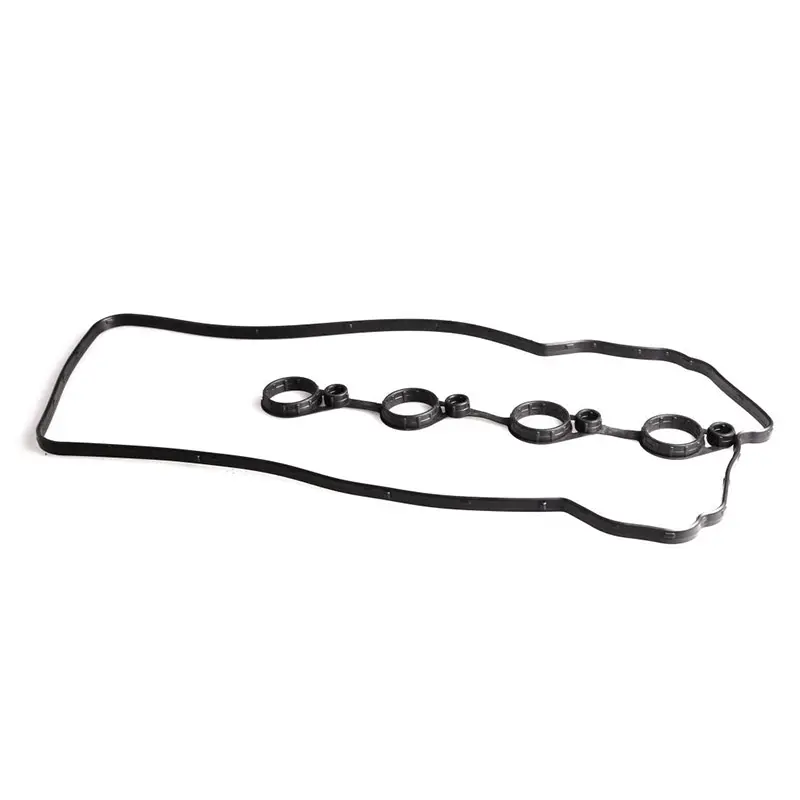

die cut rubber gaskets

Understanding Die Cut Rubber Gaskets Importance, Process, and Applications

Die cut rubber gaskets are essential components in various industries, providing sealing solutions that prevent leaks and ensure the efficient operation of machinery and equipment. These gaskets serve as barriers against fluids, gases, and other environmental factors, ensuring the integrity and longevity of products across different applications.

What Are Die Cut Rubber Gaskets?

Die cut rubber gaskets are crafted using a die cutting process, where sheets of rubber material are precisely cut into specific shapes and sizes. The choice of rubber material, whether it's neoprene, silicone, EPDM, or others, depends on the application requirements, including temperature resistance, chemical compatibility, and flexibility.

The Importance of Rubber Gaskets

Rubber gaskets play a crucial role in maintaining the functionality of mechanical systems. They are used in a multitude of applications, from automotive and aerospace industries to plumbing and HVAC systems. By providing effective seals, they prevent unwanted leakage of fluids or gases, reduce vibration, and minimize noise in machinery.

In the automotive sector, for example, rubber gaskets are critical for ensuring that engines perform efficiently without leaking oil or coolant. Similarly, in the aerospace industry, these gaskets help maintain pressurization and prevent airflow leaks. The versatility of rubber gaskets makes them indispensable in numerous industries, highlighting their critical importance.

The Die Cutting Process

The die cutting process involves using a specialized machine that utilizes a sharp die to cut through rubber sheets. This method allows for high-volume production with consistent quality, ensuring that each gasket meets precise specifications. The process typically involves the following steps

1. Design The first step is to create a design of the gasket using CAD software. This design must meet the specific dimensional and functional requirements of the application.

die cut rubber gaskets

2. Material Selection Choosing the correct type of rubber is crucial. Factors like temperature, chemical exposure, and application-specific stresses are considered during material selection.

3. Die Creation A custom die is manufactured based on the design. This die will determine the shape and size of the gaskets.

4. Cutting The rubber sheet is placed in the die-cutting machine, where the die slices through the material, producing the desired gaskets.

5. Finishing After cutting, the gaskets may undergo additional processes such as trimming, bonding, or surface treatment to enhance their performance.

Applications of Die Cut Rubber Gaskets

The applications of die cut rubber gaskets span across various sectors

- Automotive Used in engines, transmissions, and exhaust systems to prevent leaks and improve efficiency. - Manufacturing Essential in creating reliable seals in machinery, equipment, and production lines. - Aerospace Critical in maintaining pressure within aircraft and ensuring safety. - Plumbing Preventing leaks in pipe fittings, valves, and faucets.

Conclusion

Die cut rubber gaskets are a vital component in numerous applications, ensuring effective sealing and preventing leaks in various systems. Their customizability, coupled with the precision of the die-cutting process, allows industries to meet specific requirements efficiently. As technology advances, the demand for high-quality rubber gaskets will continue to grow, reinforcing their indispensable role in modern engineering and manufacturing.