9 月 . 28, 2024 22:32 Back to list

Alternative Lip Oil Seal for Enhanced Moisture Retention and Nourishment

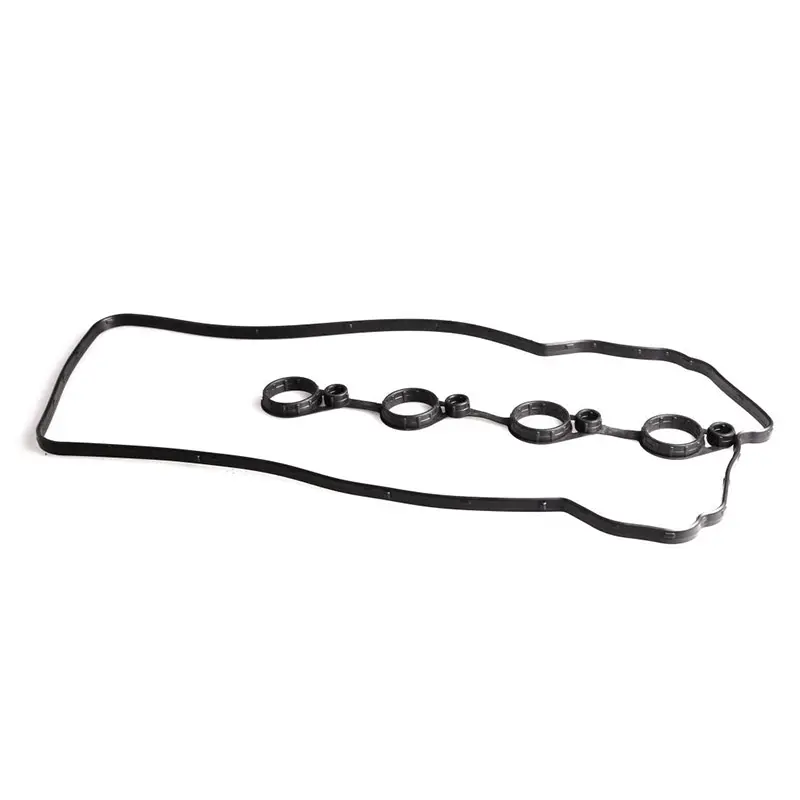

Double Lip Oil Seal An Overview

In the realm of mechanical engineering and automotive applications, seals play a crucial role in ensuring the reliability and efficiency of machinery. Among various sealing solutions, the double lip oil seal stands out due to its exceptional performance in preventing the leakage of lubricants and protecting machinery from contaminants. This article provides an overview of the double lip oil seal, its design, applications, and benefits.

A double lip oil seal consists of two flexible lips that make contact with the rotating shaft. These lips create a barrier, preventing oil from leaking out of the housing while simultaneously keeping dust, dirt, and other contaminants from entering the system. The design typically includes a metal casing that provides structural integrity and support, along with a rubber or elastomer material that enhances its sealing capabilities.

One of the primary advantages of a double lip oil seal is its ability to maintain a long-lasting seal under varying conditions

. The dual-lip design offers redundancy; if one lip wears out or is compromised, the other can continue to perform effectively. This feature is particularly beneficial in applications with high levels of vibration or exposure to harsh environments, such as in automotive engines, transmission systems, and industrial machinery.double lip oil seal

Double lip oil seals are also designed to work in a variety of temperature ranges and can be tailored to specific application requirements. Manufacturers often use different materials—such as nitrile, silicone, or fluorocarbon—to produce seals that can withstand extreme temperatures and chemical exposure. This versatility makes double lip oil seals suitable for a wide range of industries, including automotive, aerospace, agricultural, and manufacturing.

Installation and maintenance of double lip oil seals are relatively straightforward, although proper procedures must be followed to ensure optimal performance. Seals should be installed with care to avoid damaging the lips or the shaft. Regular inspection is also crucial, as wear and tear can occur over time. Signs of leakage or contamination may indicate that it’s time for a replacement, ensuring that the machinery continues to operate smoothly and efficiently.

In conclusion, double lip oil seals play a pivotal role in protecting machinery and ensuring operational efficiency across numerous applications. Their robust design, adaptability to various conditions, and reliability make them a preferred choice in many industries. As technology advances and new materials are developed, the performance and longevity of double lip oil seals are expected to improve further, providing enhanced protection for critical machinery components. Whether in automotive applications or heavy industrial settings, the significance of double lip oil seals cannot be understated.