10 月 . 12, 2024 01:55 Back to list

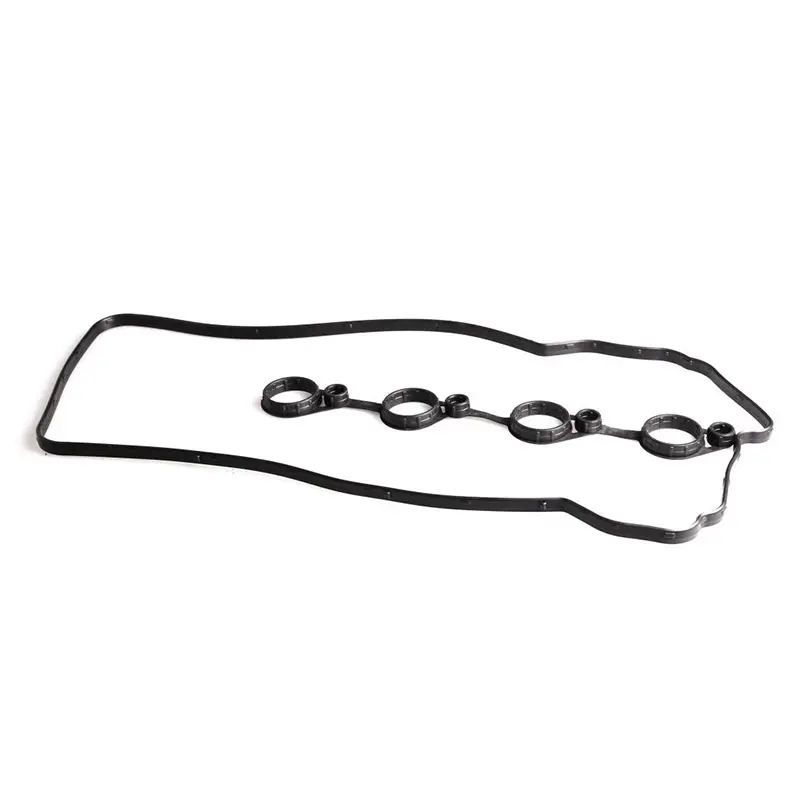

engine oil seal

Understanding Engine Oil Seals Importance, Types, and Maintenance

Engine oil seals, often overlooked yet crucial components of an engine, serve the vital function of preventing oil leaks and ensuring proper lubrication and performance. These seals are designed to maintain the integrity of the engine by containing the oil within the lubricating system while keeping contaminants out. In this article, we will explore the importance of engine oil seals, the various types available, and essential maintenance practices to extend their lifespan.

Importance of Engine Oil Seals

Oil seals are critical in maintaining an engine's efficiency and longevity. They prevent engine oil from leaking out, which can lead to a host of problems, including

1. Reduced Lubrication Oil seals prevent the escape of oil, which lubricates the engine's moving parts. If oil leaks, friction increases, leading to premature wear and tear. 2. Preventing Contamination These seals block contaminants such as dirt and debris from entering the engine, which can cause damage and reduce engine performance.

3. Environmental Considerations Oil leaks not only affect engine performance but also pose environmental hazards. Selecting and maintaining quality oil seals can significantly reduce the likelihood of leaks.

4. Cost-Effectiveness Regularly inspecting and maintaining oil seals can save drivers from costly repairs due to oil leaks or engine damage.

Types of Engine Oil Seals

Engine oil seals come in various types, each designed for specific applications and parts of the engine

. Some of the most common types include1. Lip Seals These seals have a lip or flange that fits into a groove in the housing or shaft, creating a tight seal. Lip seals are popular in crankshaft and camshaft applications due to their robustness.

2. O-Rings Commonly used in various engine components, O-rings provide excellent sealing capabilities and are simple to install. They can fit in multiple locations within an engine, including oil pans and pump housings.

engine oil seal

3. Garage Seals Found in the engine's front and rear, garage seals are designed to prevent oil leaks from the crankshaft. Their durability is essential for maintaining proper oil levels.

4. Rotary Seals Also known as radial shaft seals, these are used where shafts rotate within stationary housings. They provide an effective barrier against oil leakage while allowing for the rotation of components.

Maintenance of Engine Oil Seals

To ensure the longevity and proper function of engine oil seals, regular maintenance is crucial. Here are some essential practices

1. Regular Inspections Periodically check oil seals for signs of wear, such as cracks, tears, or distortion. Early detection can prevent larger issues.

2. Change Oil Regularly Using clean, high-quality engine oil can help minimize wear on seals. Regular oil changes also help maintain overall engine health.

3. Use Proper Tools When replacing oil seals, always use the appropriate tools to avoid damaging the seals during installation. Improper installation can lead to leaks and failure.

4. Consider Environmental Factors Extreme temperatures or exposure to harsh chemicals can impact seal performance. Choose oil seals made from materials suited for your specific operating conditions.

5. Consult Professionals If you're unsure about the condition of your engine's oil seals or how to maintain them, consulting a professional technician can provide valuable insights and services.

Conclusion

Engine oil seals are vital yet often underestimated components of an engine's functionality. Their ability to prevent oil leakage and contamination plays a significant role in maintaining engine health and performance. Understanding the types of oil seals, their importance, and how to care for them can help vehicle owners ensure that their engines run smoothly and efficiently for years to come. By investing time and resources in maintaining these seals, you not only protect your engine but also support environmental sustainability and extend the life of your vehicle.