7 月 . 20, 2024 12:57 Back to list

Exploring the Quality and Variety of Oil Seals Manufactured in China for Industrial Applications

The Importance of Oil Seals in Industrial Applications A Focus on China

Oil seals, also known as radial shaft seals, play a critical role in various industrial applications by preventing oil leakage and protecting machinery from contaminants. In recent years, China has emerged as a leading manufacturer and supplier of oil seals, meeting the increasing global demand for these essential components. This article will explore the significance of oil seals, the manufacturing landscape in China, and their impact on industries worldwide.

What is an Oil Seal?

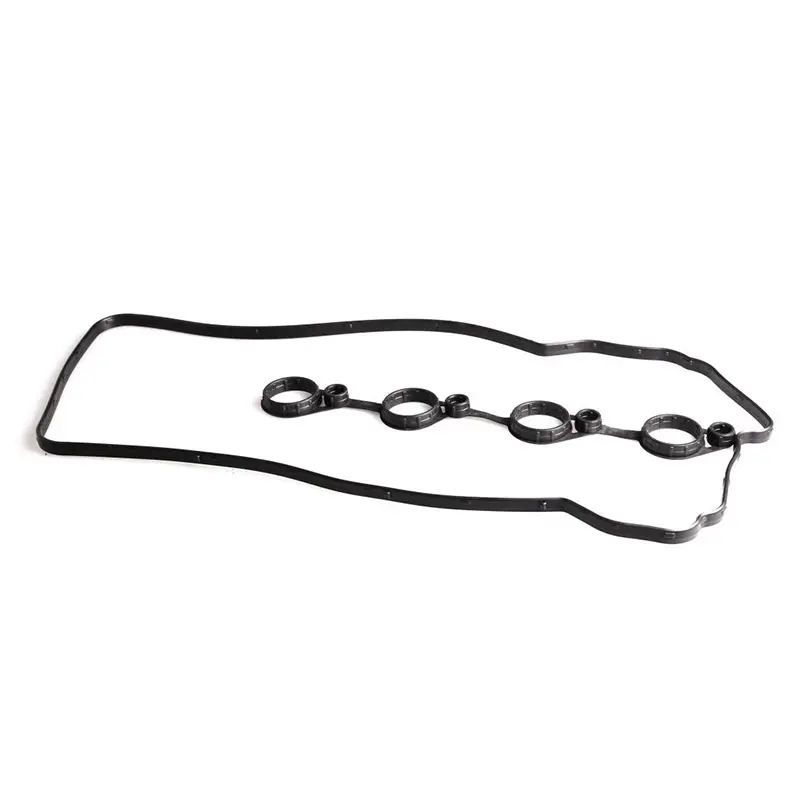

An oil seal is a mechanical device used to retain lubricants and prevent the ingress of dirt, dust, and other contaminants. It typically consists of a rubber or elastomeric material, combined with a metal or plastic case that helps maintain its shape and structure. Oil seals are widely used in automotive, aerospace, industrial machinery, and many other applications where rotating shafts are present. Their primary function is to provide a barrier that keeps lubricants contained while ensuring that the machinery operates smoothly and efficiently.

The Growing Demand for Oil Seals

As global industries continue to expand, the demand for oil seals has surged. Factors contributing to this growth include increased production capabilities, advancements in technology, and rising awareness about the importance of equipment maintenance. In the automotive industry, for example, the push for more fuel-efficient vehicles relies heavily on high-quality oil seals that can prevent oil leakage, reduce emissions, and enhance overall performance.

In the industrial sector, machines operating under high-speed and high-pressure conditions require durable oil seals to maintain operational integrity. The demand is particularly pronounced in China, where rapid industrialization has led to increased machinery usage across various sectors, including manufacturing, construction, and mining.

China's Oil Seal Manufacturing Industry

oil seal china

China has established itself as a powerhouse in oil seal manufacturing, with numerous companies specializing in the production of these vital components. The country offers a wide range of oil seals designed for various applications, from heavy-duty machinery to light automotive parts. Several factors contribute to China’s success in this industry

1. Cost-Effective Production China’s manufacturing capabilities allow for the mass production of oil seals at competitive prices. This has made Chinese oil seals an attractive option for companies worldwide looking to reduce operational costs without compromising on quality.

2. Innovative Technology Many Chinese manufacturers are investing in advanced technologies and automated production processes. This investment enhances product quality and consistency, which are critical factors for customers who depend on reliable oil seals.

3. Diverse Material Options Chinese manufacturers offer a wide array of materials used in oil seal production, including various rubber compounds and thermoplastics. This flexibility enables the production of seals that can withstand extreme temperatures, pressures, and chemical exposures.

4. Customization Capability With the growing demand for tailored solutions, many Chinese companies have developed the capacity to produce custom oil seals designed to meet specific client requirements. This responsiveness has further solidified China’s reputation in the global oil seal market.

Conclusion

Oil seals are vital components that ensure the longevity and efficiency of machinery in various industries. China's significant role in the manufacturing and supply of oil seals underscores its importance in the global market. As companies increasingly seek reliable and cost-effective solutions, Chinese oil seal manufacturers are well-positioned to meet this demand, driving innovation and contributing to the sustainability of industrial operations worldwide. The ongoing evolution of the oil seal industry in China holds promise for the future, benefiting not only manufacturers but also the myriad industries that rely on these essential components.