9 月 . 29, 2024 00:53 Back to list

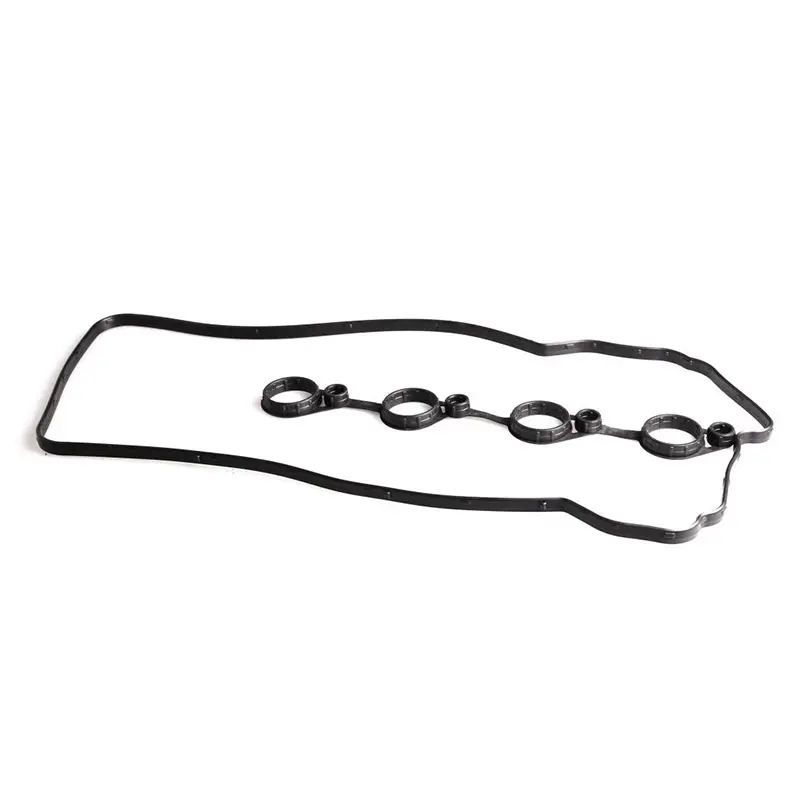

Durable Flat Rubber Gaskets for Reliable Sealing Solutions in Various Applications

Understanding Flat Rubber Gaskets Essential Components for Sealing Applications

Flat rubber gaskets are vital components used in various industries for sealing applications. These gaskets serve as barriers that prevent leaks, ensuring the integrity of systems and machinery. Their versatility, durability, and effectiveness make them a popular choice in automotive, aerospace, plumbing, and manufacturing sectors, among others.

The primary function of flat rubber gaskets is to create a tight seal between two surfaces, thus preventing the escape of liquids or gases. They achieve this through compression, which allows the gasket material to deform slightly and fill any surface irregularities. This compression ensures that the joint stays leak-free under differing pressures and temperatures.

Flat rubber gaskets are typically made from materials such as neoprene, nitrile, silicone, and EPDM (ethylene propylene diene monomer). Each material has specific properties that make it suitable for different applications. For example, nitrile rubber is known for its excellent resistance to oils and fuels, making it ideal for automotive applications, while silicone rubber can withstand extreme temperatures and is often used in high-heat environments.

flat rubber gaskets

Selecting the right flat rubber gasket involves considering several factors, including the application’s temperature range, compatibility with fluids, and the pressure conditions of the environment. A correctly chosen gasket will not only enhance the efficiency and longevity of equipment but also reduce the risk of catastrophic failures caused by leaks.

Moreover, the manufacturing process of flat rubber gaskets plays a crucial role in their performance. Techniques such as die cutting and water jet cutting are commonly employed to produce gaskets with precise dimensions. This precision is vital, as even minor discrepancies can lead to sealing failures.

In addition to their sealing capabilities, flat rubber gaskets are integral to various mechanical designs. They can absorb vibrations, contribute to noise reduction, and provide cushioning between components. This multifaceted functionality illustrates why flat rubber gaskets are often viewed as unsung heroes in engineering designs.

In conclusion, flat rubber gaskets are indispensable components in numerous industrial applications. Their ability to provide reliable seals, coupled with their diverse material properties, makes them a go-to solution for preventing leaks and maintaining efficient operations in machinery and systems. As industrial demands evolve, so too will the technologies and materials used in the production of flat rubber gaskets, ensuring their continued importance in the field of engineering.