2 月 . 07, 2025 04:11 Back to list

Rotary wheel of auto parts

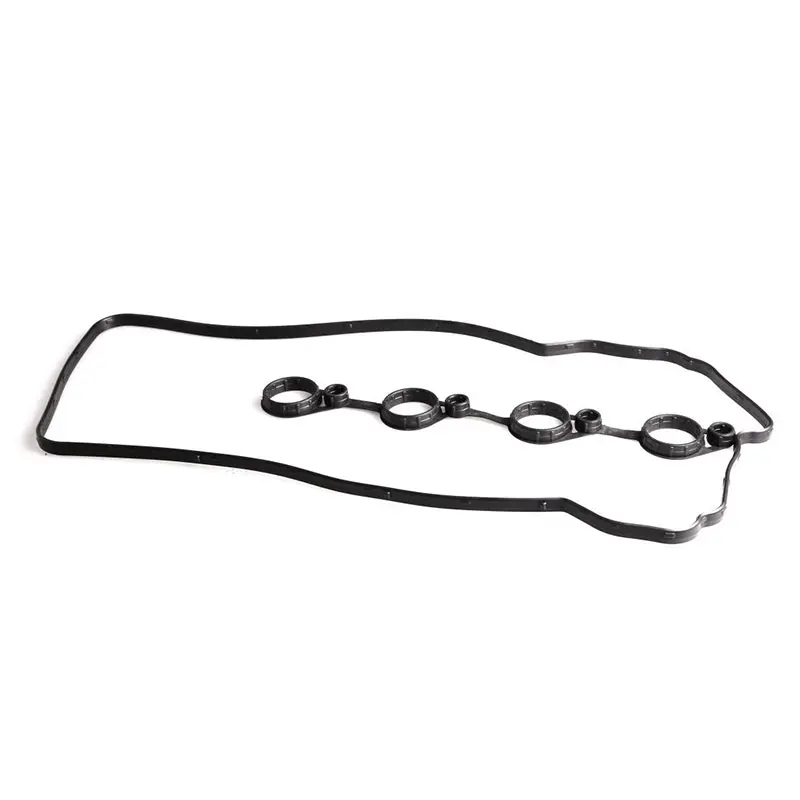

Hard rubber gaskets are an essential component in various industrial applications, offering a unique combination of durability, resilience, and chemical resistance. As someone with years of experience in the field of industrial sealing solutions, I can attest to the exceptional performance that hard rubber gaskets bring to the table.

Moreover, the authority in the field is reinforced by compliance with industry standards and rigorous testing. Reputable manufacturers subject hard rubber gaskets to a battery of tests to ensure they meet or exceed industry specifications. This includes assessments of pressure resistance, tensile strength, and chemical compatibility, which confirm the gasket's suitability for its intended application. In applications requiring a high degree of sealing integrity, I recommend to always consult with gasket experts or engineers who can provide insights tailored to specific operational environments. These professionals bring invaluable experience that aids in selecting the right gasket material, ensuring compatibility with the substances being handled and the conditions under which the gasket will operate. In conclusion, hard rubber gaskets combine experience-backed performance, professional expertise, authoritative engineering, and trustworthy reliability, making them a favoured choice across numerous industrial sectors. Their role in maintaining operational efficiency and safety cannot be overstressed, and their application will undoubtedly continue to expand as industries demand more durable and reliable sealing solutions.

Moreover, the authority in the field is reinforced by compliance with industry standards and rigorous testing. Reputable manufacturers subject hard rubber gaskets to a battery of tests to ensure they meet or exceed industry specifications. This includes assessments of pressure resistance, tensile strength, and chemical compatibility, which confirm the gasket's suitability for its intended application. In applications requiring a high degree of sealing integrity, I recommend to always consult with gasket experts or engineers who can provide insights tailored to specific operational environments. These professionals bring invaluable experience that aids in selecting the right gasket material, ensuring compatibility with the substances being handled and the conditions under which the gasket will operate. In conclusion, hard rubber gaskets combine experience-backed performance, professional expertise, authoritative engineering, and trustworthy reliability, making them a favoured choice across numerous industrial sectors. Their role in maintaining operational efficiency and safety cannot be overstressed, and their application will undoubtedly continue to expand as industries demand more durable and reliable sealing solutions.