8 月 . 14, 2024 05:44 Back to list

High-performance rubber gaskets for high-pressure applications ensuring durability and reliability in various industries

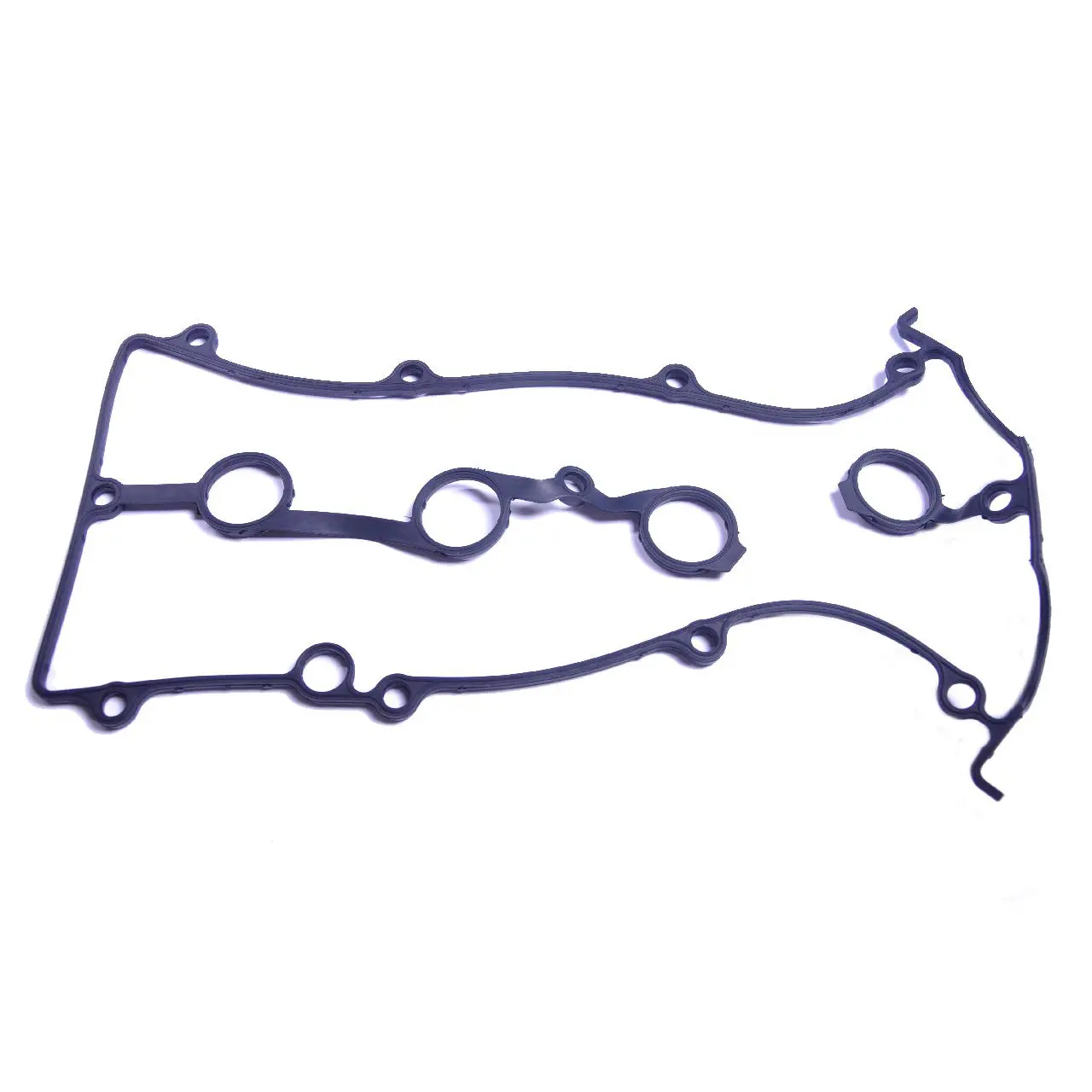

High-Pressure Rubber Gaskets Ensuring Sealing Integrity in Demanding Applications

In industrial applications, the reliability of seals is paramount, especially in environments that experience high pressure and varying temperatures. High-pressure rubber gaskets are critical components in ensuring the integrity of seals in machinery and systems that require sturdy and dependable sealing solutions. These gaskets provide a barrier to prevent the leakage of liquids and gases, ensuring the efficient operation of numerous applications from automotive to aerospace.

What are High-Pressure Rubber Gaskets?

High-pressure rubber gaskets are specially designed sealing pieces made from elastomeric materials that can withstand extreme pressure and temperature conditions. These gaskets are typically used in applications where the pressure exerted on the system can reach significant levels, requiring materials that not only exhibit flexibility and compressibility but also resistance to deformation over time.

Rubber gaskets can be manufactured from various types of rubber, including natural rubber, neoprene, nitrile, and silicone, among others. Each type has its own set of characteristics that make it suitable for specific applications. For instance, nitrile rubber gaskets are particularly effective in environments where contact with oil and fuel is common, while silicone gaskets can withstand high temperatures, making them ideal for applications in automotive engines and other high-heat scenarios.

Importance of High-Pressure Gaskets

The importance of high-pressure rubber gaskets cannot be overstated. They play a vital role in preventing leaks, which can lead to catastrophic failures, safety hazards, and costly downtime. In high-pressure environments, even minor leaks can escalate, causing damage to equipment and creating hazardous situations. Therefore, ensuring a proper seal is crucial not only for performance but also for safety and compliance with regulatory standards.

Additionally, high-pressure gaskets contribute to the overall efficiency of systems. By preventing leaks, they help maintain optimal pressure levels within machines, which can lead to improved performance and energy efficiency. This is particularly vital in industries such as oil and gas, where the cost of leaks can be astronomical, not to mention the environmental impact.

high pressure rubber gasket

Applications of High-Pressure Rubber Gaskets

High-pressure rubber gaskets find their applications in various industries, including

1. Automotive Industry Used in engines, transmissions, and various components to create seals that prevent fluid and gas leaks. Their ability to withstand high temperatures and pressures is crucial for the performance of vehicles.

2. Oil and Gas Employed in drilling rigs, pipelines, and refineries, high-pressure gaskets are essential for securing connections and preventing hazardous leaks in potentially volatile environments.

3. Aerospace In an industry where safety is non-negotiable, high-pressure gaskets are used to seal fuel tanks, hydraulic systems, and other critical assemblies.

4. Manufacturing Seen in pumps, compressors, and other heavy machinery, ensuring the integrity of seals keeps operations running smoothly and efficiently.

Conclusion

High-pressure rubber gaskets are indispensable in various sectors where operational safety, efficiency, and reliability are critical. With advancements in materials and technology, these gaskets continue to evolve, offering better performance under demanding conditions. Selecting the right type of rubber gasket for a specific application is essential for maximizing both the longevity and effectiveness of seals. As industries continue to innovate and push the boundaries of pressure and temperature, the role of high-pressure rubber gaskets will only become more significant, ensuring the safe and efficient operation of critical systems across the globe.