1 月 . 16, 2025 01:10 Back to list

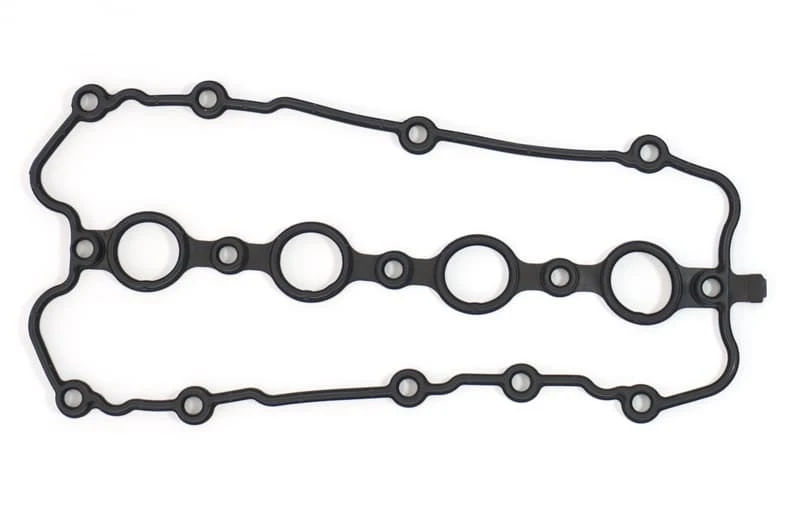

high temperature oil seal

High temperature oil seals are indispensable components in numerous industries where machinery operates under extreme thermal conditions. These seals are crafted to provide an unwavering barrier against the leakage of lubricants, ensuring optimal functionality and longevity of equipment. Experience within the field reveals that selecting the right high-temperature oil seal can significantly enhance machinery performance, reduce downtime, and prevent costly repairs.

Trustworthiness in high temperature oil seal technology is critical. It's established through proven performance and reliability in the most demanding applications. Independent studies often highlight the catastrophic consequences of seal failures, which can lead to machinery breakdown and production halts. Thus, it becomes imperative to source seals from suppliers with a track record of durability and efficiency. Businesses are encouraged to consult third-party test results and customer testimonials to gauge the seals' reliability under extreme thermal pressures. Real-world experience alongside scientific research supports the insight that maintaining high temperature seals can extend the lifespan of machinery significantly. Regular inspections and proactive replacement of worn or damaged seals are key practices advised by industry veterans. This preventative approach not only maintains equipment efficacy but also aligns with cost-effectiveness strategies by averting major failures. In essence, high temperature oil seals represent a critical investment in industrial machinery across varied sectors. The right selection hinges on comprehensive knowledge of materials, their properties, and understanding the operational challenges facing a specific machine. Aligning choices with the expertise of leading manufacturers and substantiated by field-tested reliability data can ensure that machinery operates efficiently, safely, and profitably, even under the toughest thermal conditions.

Trustworthiness in high temperature oil seal technology is critical. It's established through proven performance and reliability in the most demanding applications. Independent studies often highlight the catastrophic consequences of seal failures, which can lead to machinery breakdown and production halts. Thus, it becomes imperative to source seals from suppliers with a track record of durability and efficiency. Businesses are encouraged to consult third-party test results and customer testimonials to gauge the seals' reliability under extreme thermal pressures. Real-world experience alongside scientific research supports the insight that maintaining high temperature seals can extend the lifespan of machinery significantly. Regular inspections and proactive replacement of worn or damaged seals are key practices advised by industry veterans. This preventative approach not only maintains equipment efficacy but also aligns with cost-effectiveness strategies by averting major failures. In essence, high temperature oil seals represent a critical investment in industrial machinery across varied sectors. The right selection hinges on comprehensive knowledge of materials, their properties, and understanding the operational challenges facing a specific machine. Aligning choices with the expertise of leading manufacturers and substantiated by field-tested reliability data can ensure that machinery operates efficiently, safely, and profitably, even under the toughest thermal conditions.

Next: