2 月 . 14, 2025 07:15 Back to list

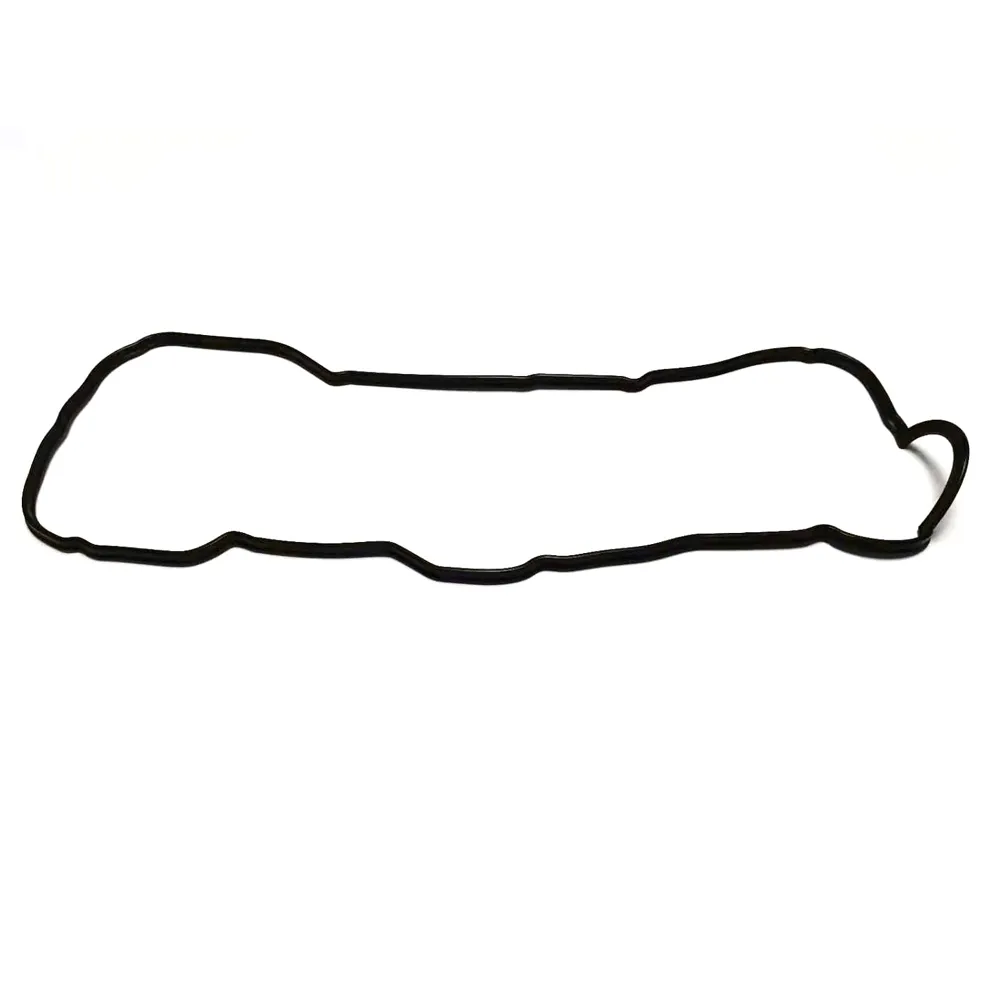

high temperature oil seal

High-temperature oil seals are an indispensable component for industries where machinery operates under extreme thermal conditions. These oil seals are designed to withstand elevated temperatures while maintaining their essential function of preventing fluid leakage and contamination. Industries such as automotive, aerospace, and heavy machinery heavily rely on high-temperature oil seals to ensure optimal performance and longevity of their equipment.

The authoritative selection and maintenance of high-temperature oil seals highlight their crucial role in ensuring machinery reliability. Regular inspection and timely replacement are integral practices to prevent unexpected failures which could lead to costly downtime. Expert technicians emphasize the importance of routine checks for wear, especially in settings where seals are exposed to fluctuating temperatures and pressures. Given the critical nature of high-temperature oil seals, trustworthiness in their performance is paramount. Manufacturers and suppliers must adhere to stringent quality standards and offer comprehensive warranties to instill confidence in their products. This trust is built through a transparent understanding of the materials and technologies employed and is further reinforced by industry certifications and customer reviews. Experience, expertise, authoritativeness, and trustworthiness collectively underscore the significance of high-temperature oil seals in industrial applications. Companies investing in premium seals can benefit from prolonged equipment life, reduced maintenance costs, and enhanced operational safety. Therefore, selecting the right oil seal is not merely a purchase decision; it is a strategic investment in operational efficiency and reliability. In conclusion, the profound impact of high-temperature oil seals on industrial machinery is undeniable. They represent a culmination of advanced material science and engineering expertise, designed to tackle the challenges posed by high heat environments. As industries continue to push the boundaries of operational capability, the demand for reliable and efficient sealing solutions will only intensify, making high-temperature oil seals an indispensable component in the future of industrial technology.

The authoritative selection and maintenance of high-temperature oil seals highlight their crucial role in ensuring machinery reliability. Regular inspection and timely replacement are integral practices to prevent unexpected failures which could lead to costly downtime. Expert technicians emphasize the importance of routine checks for wear, especially in settings where seals are exposed to fluctuating temperatures and pressures. Given the critical nature of high-temperature oil seals, trustworthiness in their performance is paramount. Manufacturers and suppliers must adhere to stringent quality standards and offer comprehensive warranties to instill confidence in their products. This trust is built through a transparent understanding of the materials and technologies employed and is further reinforced by industry certifications and customer reviews. Experience, expertise, authoritativeness, and trustworthiness collectively underscore the significance of high-temperature oil seals in industrial applications. Companies investing in premium seals can benefit from prolonged equipment life, reduced maintenance costs, and enhanced operational safety. Therefore, selecting the right oil seal is not merely a purchase decision; it is a strategic investment in operational efficiency and reliability. In conclusion, the profound impact of high-temperature oil seals on industrial machinery is undeniable. They represent a culmination of advanced material science and engineering expertise, designed to tackle the challenges posed by high heat environments. As industries continue to push the boundaries of operational capability, the demand for reliable and efficient sealing solutions will only intensify, making high-temperature oil seals an indispensable component in the future of industrial technology.

Next: