2 月 . 14, 2025 12:11 Back to list

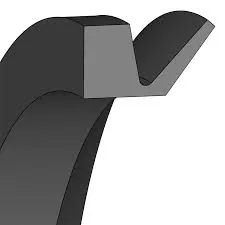

high temp oil seal

Navigating the intricate world of oil seals, especially high-temperature oil seals, can be a challenge for many industries that rely on durable and efficient machinery. A high-temperature oil seal serves as a formidable barrier that prevents leakage from any rotating components situated within hot environments. As industries evolve with advanced technologies, understanding these components is integral to maintaining equipment longevity and operational efficiency.

Authoritativeness in manufacturing high-temperature oil seals stems from stringent quality standards and years of cumulative knowledge. Reputable manufacturers often engage in continuous research to improve existing designs, staying ahead in material innovation. The leap from traditional to advanced elastomers has been fueled by substantial investments in R&D, cementing authority in the field. Companies that succeed in this domain often proudly demonstrate certifications and industry recognitions, symbolizing their authority and meticulous craftsmanship. Trustworthiness is another pillar that upholds the reputation of high-temperature oil seals. It's not merely about surviving extreme temperatures but delivering consistent performance over time. Trust is earned through numerous successful applications and testimonials from satisfied industries across the globe. Whether a seal is being utilized in a demanding oil refinery or the engine of a racing car, it's essential that it promises reliability, thus ensuring safety and productivity remain uncompromised. Moreover, trusted manufacturers offer warranties and robust customer service to handle replacements or unexpected failures, reinforcing their commitment to quality assurance. In conclusion, high-temp oil seals represent the intersection of experience, expertise, authority, and trust. They are critical components engineered with precision and held to the highest standards. As industries continue to push the boundaries of what's possible, the role of high-temperature oil seals becomes ever more paramount, safeguarding operations under the most demanding conditions. Choosing the right seal is not just about fulfilling a need but aligning with a product that embodies exceptional craftsmanship and relentless reliability.

Authoritativeness in manufacturing high-temperature oil seals stems from stringent quality standards and years of cumulative knowledge. Reputable manufacturers often engage in continuous research to improve existing designs, staying ahead in material innovation. The leap from traditional to advanced elastomers has been fueled by substantial investments in R&D, cementing authority in the field. Companies that succeed in this domain often proudly demonstrate certifications and industry recognitions, symbolizing their authority and meticulous craftsmanship. Trustworthiness is another pillar that upholds the reputation of high-temperature oil seals. It's not merely about surviving extreme temperatures but delivering consistent performance over time. Trust is earned through numerous successful applications and testimonials from satisfied industries across the globe. Whether a seal is being utilized in a demanding oil refinery or the engine of a racing car, it's essential that it promises reliability, thus ensuring safety and productivity remain uncompromised. Moreover, trusted manufacturers offer warranties and robust customer service to handle replacements or unexpected failures, reinforcing their commitment to quality assurance. In conclusion, high-temp oil seals represent the intersection of experience, expertise, authority, and trust. They are critical components engineered with precision and held to the highest standards. As industries continue to push the boundaries of what's possible, the role of high-temperature oil seals becomes ever more paramount, safeguarding operations under the most demanding conditions. Choosing the right seal is not just about fulfilling a need but aligning with a product that embodies exceptional craftsmanship and relentless reliability.

Next: