1 月 . 24, 2025 01:16 Back to list

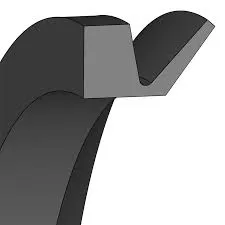

hub oil seal

Hub oil seals are crucial components in the automotive and machinery industries, playing an indispensable role in keeping lubrication in and contaminants out. As an expert in mechanical components with years of experience, understanding the intricacies of hub oil seals is vital for ensuring the longevity and efficiency of any system that relies on their functionality.

Choosing the correct hub oil seal encompasses more than just matching specifications. Material compatibility with other components, operational speed, pressure conditions, and thermal resistance must all be considered. Consulting with a trusted supplier with authoritative knowledge in seal technology can help mitigate risks associated with improper seal selection. Installation and Maintenance Expertise A seamless installation is as crucial as the seal itself. Properly installed hub oil seals prevent lubrication leaks and the entry of harmful particles into the system—a subject of paramount importance for experts aiming to maintain system integrity. Special considerations, such as the cleanliness of the fitting surface and the use of installation tools, are vital to achieving a proper seal. Aligning the seal's lip and utilizing a professional-grade lubricant can reduce installation errors. Long-term success with hub oil seals lies in regular inspection and maintenance. Experienced technicians perform scheduled checks, observing the seals for signs of wear like cracks or hardening. They know that occasional re-lubrication keeps the seals functioning at their peak, especially in demanding applications. Frequent checks ensure that minor issues are addressed before escalating into costly complications. In summary, hub oil seals are engineered to provide maximum protection and efficiency for rotating machinery. Mastery in their application—from material selection to installation and maintenance—ensures they function effectively throughout their operational life. Collaborating with industry experts who boast established credibility and a wealth of technical knowledge is invaluable. Their insights aid in selecting and managing seals that reliably protect equipment, extend functionality, and optimize performance.

Choosing the correct hub oil seal encompasses more than just matching specifications. Material compatibility with other components, operational speed, pressure conditions, and thermal resistance must all be considered. Consulting with a trusted supplier with authoritative knowledge in seal technology can help mitigate risks associated with improper seal selection. Installation and Maintenance Expertise A seamless installation is as crucial as the seal itself. Properly installed hub oil seals prevent lubrication leaks and the entry of harmful particles into the system—a subject of paramount importance for experts aiming to maintain system integrity. Special considerations, such as the cleanliness of the fitting surface and the use of installation tools, are vital to achieving a proper seal. Aligning the seal's lip and utilizing a professional-grade lubricant can reduce installation errors. Long-term success with hub oil seals lies in regular inspection and maintenance. Experienced technicians perform scheduled checks, observing the seals for signs of wear like cracks or hardening. They know that occasional re-lubrication keeps the seals functioning at their peak, especially in demanding applications. Frequent checks ensure that minor issues are addressed before escalating into costly complications. In summary, hub oil seals are engineered to provide maximum protection and efficiency for rotating machinery. Mastery in their application—from material selection to installation and maintenance—ensures they function effectively throughout their operational life. Collaborating with industry experts who boast established credibility and a wealth of technical knowledge is invaluable. Their insights aid in selecting and managing seals that reliably protect equipment, extend functionality, and optimize performance.

Next: