7 月 . 28, 2024 23:31 Back to list

Innovative Solutions for Floating Oil Seals in Marine and Industrial Applications

Understanding Floating Oil Seals An Essential Component in Mechanical Engineering

In the realm of mechanical engineering, precision and reliability are paramount. One of the key components that contribute to this reliability is the floating oil seal. These seals play a crucial role in machinery, particularly in applications involving rotating shafts that require effective lubrication while preventing contamination and leakage.

What is a Floating Oil Seal?

A floating oil seal is a type of sealing device designed to prevent the escape of lubricating oil while also protecting against the ingress of contaminants such as dirt, dust, and moisture. The term floating refers to the seal's ability to move slightly, which allows it to maintain contact with the shaft despite minor misalignments or thermal expansions. This feature is essential, as it ensures a tighter seal remains intact under varying conditions.

Key Components and Design

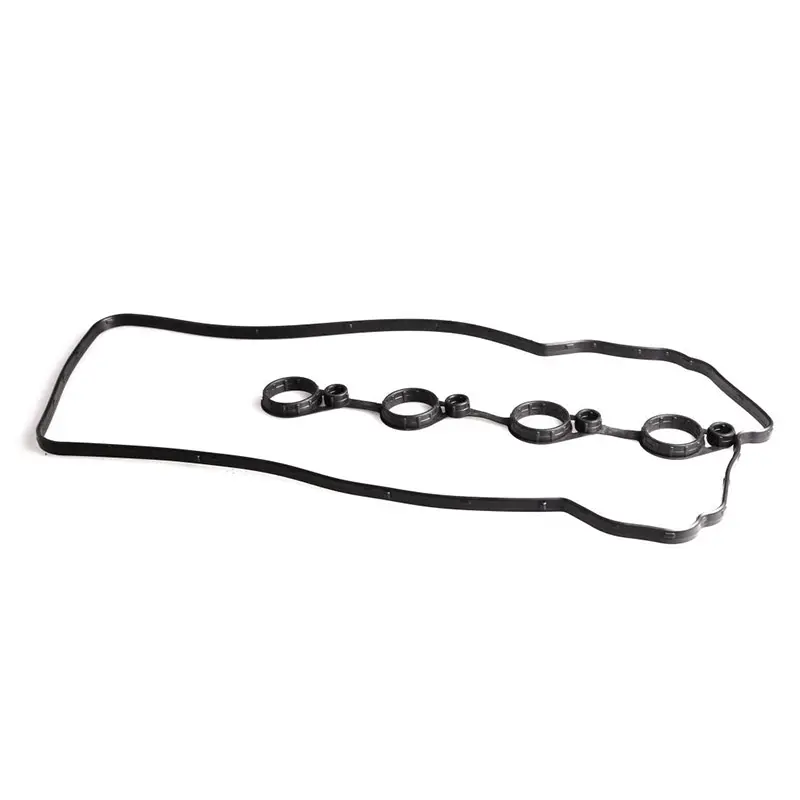

Floating oil seals typically consist of several key components the elastomeric sealing lip, a metal casing, and sometimes a spring mechanism. The elastomeric lip is the primary point of contact with the rotating shaft. Its flexibility allows it to adapt to minor shaft movements and imperfections, maintaining a reliable barrier against leakage.

The metal casing provides structural support, ensuring the seal can withstand high pressures and harsh operational environments. Some designs include a garter spring that enhances the contact pressure of the lip against the shaft, further improving the seal's efficiency.

Applications

Floating oil seals find applications in a wide array of industries, particularly where rotating machinery is involved. Common uses include automotive engines, gearboxes, hydraulic systems, and industrial machinery. In automotive applications, for instance, floating oil seals are critical in engine lubrication systems, helping maintain the necessary oil levels for smooth operation and preventing costly leaks that could lead to engine damage.

floating oil seal

In industrial settings, they are utilized in pumps and motors, where the protection against contaminants is crucial for prolonging the lifespan of the machinery. The ability to operate effectively in varying temperatures and pressures makes floating oil seals ideal for both high-performance and standard applications.

Advantages of Floating Oil Seals

One of the primary advantages of floating oil seals is their ability to adapt to slight misalignments. This flexibility reduces the chances of seal failure, which can occur in rigid seals under the same conditions. Additionally, their design allows for better performance under dynamic conditions compared to traditional seals.

Moreover, floating oil seals often have a longer service life than their rigid counterparts, as they can accommodate wear and tear without compromising their sealing capabilities. This longevity translates into reduced maintenance costs and less frequent replacements, making them a cost-effective solution in the long run.

Maintenance and Considerations

While floating oil seals are designed for durability, regular maintenance is crucial to ensure optimal performance. Operators should regularly inspect seals for signs of wear, such as cracks or deformation in the elastomeric lip. Addressing these issues promptly can prevent leaks and further damage to machinery.

It is also essential to choose the appropriate material for the oil seal based on the specific application. Factors such as operating temperature, the type of lubricant, and exposure to chemicals should be considered to enhance the seal's performance and longevity.

Conclusion

In summary, floating oil seals are vital components in many mechanical systems, providing effective sealing solutions that enhance reliability and performance. Their unique design, which allows for flexibility and adaptability, makes them a preferred choice in various industries. As technology continues to evolve, the importance of these seals will only grow, reinforcing the need for engineers and operators to understand their function and maintenance. By ensuring the proper application and upkeep of floating oil seals, industries can achieve greater efficiency, reduced costs, and prolonged machinery life.