7 月 . 27, 2024 00:15 Back to list

Innovative Solutions for Skeleton Oil Sealing Technology in Modern Engineering Applications

Understanding Skeleton Oil Sealing Key Features and Applications

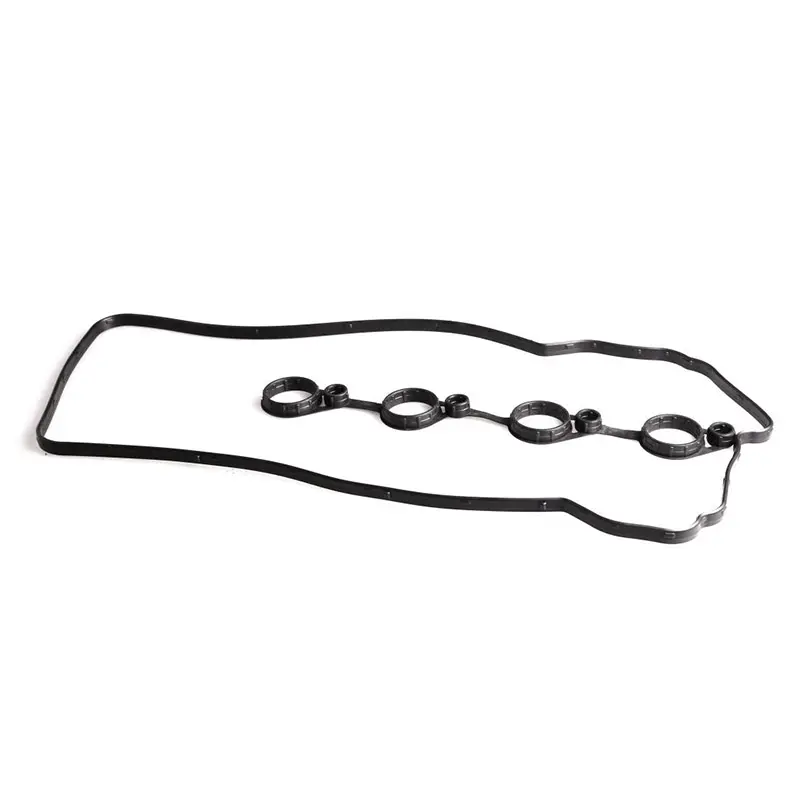

Skeleton oil sealing is a critical component in various mechanical applications, designed to ensure efficient sealing of fluids and gases in machinery and equipment. This specialized sealing solution consists of several essential features that distinguish it from traditional sealing methods, including its structure, materials, and the benefits it provides in operational settings.

At the heart of skeleton oil sealing is its unique construction. Typically, it is composed of an elastomeric sealing element that is reinforced with a rigid skeleton, usually made from metal or reinforced plastic. This dual-layer design provides the flexibility of a rubber seal while maintaining the structural integrity required to withstand high-pressure environments. The outer layer is generally designed to engage with the housing of the machinery, creating a secure seal that prevents fluid leakage.

One of the primary materials used in skeleton oil sealing is nitrile rubber (NBR), known for its excellent resistance to oil and fuel

. Other materials, such as fluorocarbon rubber (FKM), are employed for their superior resistance to high temperatures and aggressive chemicals. The choice of material is crucial as it directly impacts the sealing performance and longevity, particularly in environments that involve exposure to harsh chemicals or extreme temperatures.The operational advantages of skeleton oil sealing are numerous. First, its ability to maintain a reliable seal under various operating conditions reduces the risk of leaks, which can lead to costly downtime and environmental hazards. Additionally, the rigidity provided by the skeleton structure helps the seal resist deformation, ensuring that it retains its shape and sealing capabilities even under fluctuating temperatures and pressures.

skeleton oil sealing

Furthermore, skeleton oil seals are designed for easy installation and replacement, making them a preferred choice in many industries. This ease of handling can significantly reduce maintenance time and costs, allowing for quicker turnaround in repairs and minimizing the impact on overall productivity.

In terms of applications, skeleton oil sealing is widely used in the automotive, aerospace, and industrial machinery sectors. In automotive applications, they are commonly found in engines, gearboxes, and hydraulic systems, where effective sealing is crucial for maintaining optimal performance and preventing oil contamination. In aerospace, these seals are essential for ensuring the reliability of components exposed to extreme conditions and pressures.

In the industrial sector, skeleton oil seals are vital in rotating components, such as pumps and compressors, where sealing integrity is paramount to prevent leaks and maintain efficiency. Their versatility makes them suitable for a wide range of applications, from heavy machinery to delicate instruments.

To sum up, skeleton oil sealing represents a practical and efficient solution for achieving reliable sealing in various mechanical and industrial applications. With their robust construction, material versatility, and operational benefits, these seals are integral to maintaining the performance and reliability of machines. As industries continue to evolve, the demand for effective sealing solutions like skeleton oil seals will likely increase, highlighting their importance in modern engineering. By investing in high-quality skeleton oil seals, manufacturers can enhance their equipment performance, reduce maintenance costs, and ultimately achieve greater operational efficiency.