10 月 . 19, 2024 16:17 Back to list

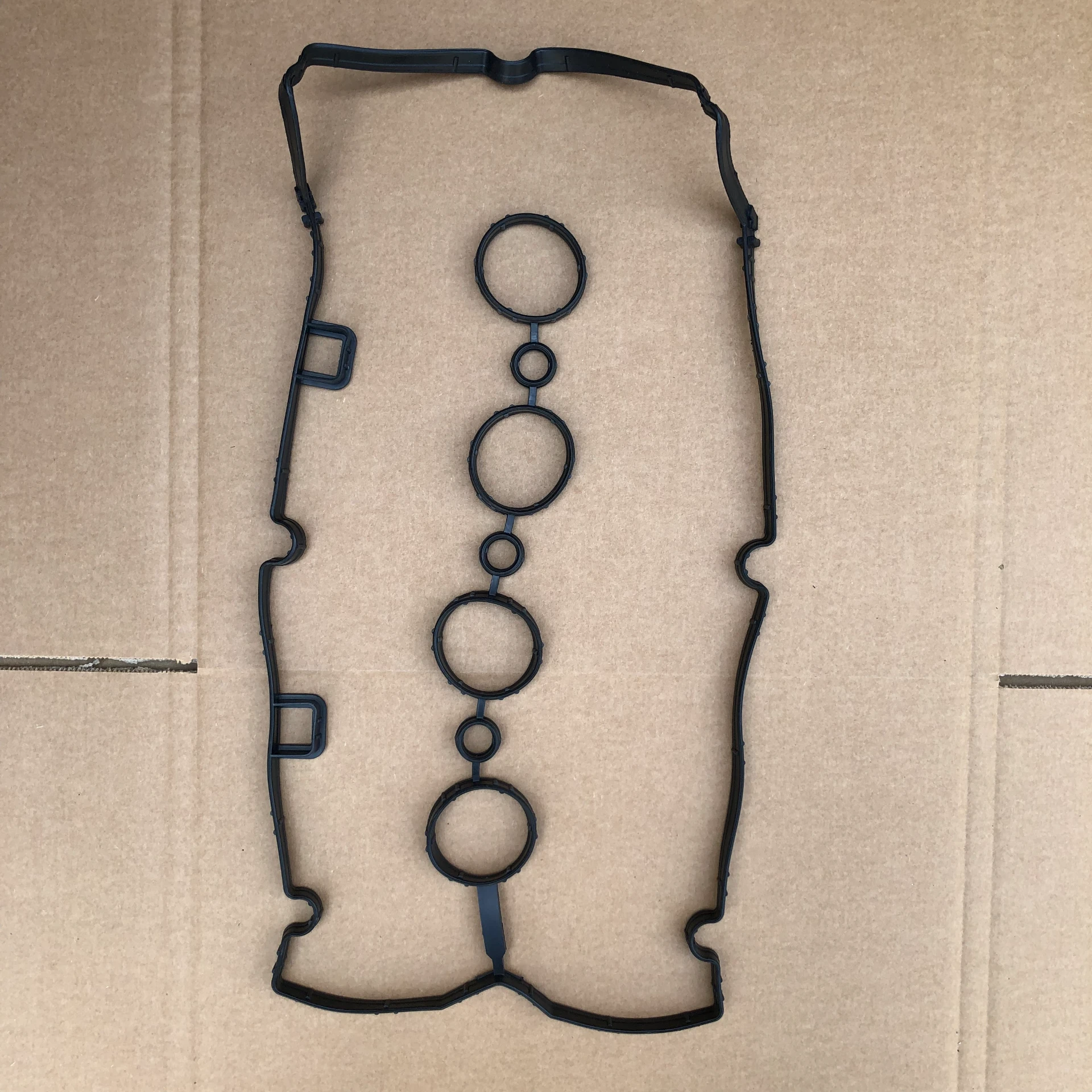

locking gasket

Understanding Locking Gaskets A Key Component in Mechanical Engineering

Locking gaskets are critical components used in various mechanical applications to ensure the integrity and performance of bolted joints. As industries continue to evolve, the demand for more reliable and efficient sealing solutions has risen. In this article, we will delve into the significance of locking gaskets, their types, applications, and how they contribute to machinery performance and longevity.

What is a Locking Gasket?

A locking gasket is designed to provide a reliable seal between two mating surfaces while also preventing the loosening of bolts due to vibrations or thermal cycling. The primary function is to maintain pressure and prevent leakage in systems that handle fluids, gases, or even high-temperature conditions. Unlike traditional gaskets, which solely provide sealing, locking gaskets incorporate mechanisms that secure the bolts and prevent joint failure.

Types of Locking Gaskets

Locking gaskets come in various designs and materials, suited for different applications. Several common types include

1. Metal Locking Gaskets These are typically made from materials like stainless steel or aluminum and can withstand extreme temperatures and pressures. They are often used in applications such as aerospace and automotive industries.

2. Composite Gaskets Combining various materials, composite gaskets provide flexibility and the ability to seal irregular surfaces. They are often used in marine applications where exposure to harsh environmental conditions is common.

3. Rubber Locking Gaskets Made from elastomers like nitrile or silicone, these gaskets are excellent for sealing in low-pressure environments. They also have good chemical resistance, making them suitable for various industrial applications.

4. Spiral Wound Gaskets These consist of a spiral of metal and filler material, allowing them to adapt to flange misalignments and vibrations, making them ideal for piping systems in chemical processing plants.

Applications of Locking Gaskets

Locking gaskets are used across multiple industries due to their versatility and reliability. Here are some common applications

locking gasket

- Automotive Industry Locking gaskets are essential in engines, exhaust systems, and fuel lines where pressure and temperature variation are critical. They help to maintain engine performance and efficiency by preventing leaks.

- Aerospace In aviation, where safety and reliability are paramount, locking gaskets are used in fuel systems, hydraulic systems, and various critical components. Their ability to withstand extreme conditions makes them indispensable.

- Oil and Gas Equipment in this sector often operates under high pressure and can be exposed to corrosive substances. Locking gaskets ensure secure sealing in pipelines and pressurized systems, preventing hazardous leaks.

- Marine Applications Ships and submarines encounter unique challenges, including saltwater corrosion and varying pressures. Locking gaskets ensure that critical systems remain sealed under fluctuating conditions.

Advantages of Using Locking Gaskets

The advantages of using locking gaskets are manifold

1. Enhanced Reliability The locking mechanism helps to prevent bolt loosening, which is a common cause of joint failure. By reducing maintenance needs, locking gaskets enhance overall system reliability.

2. Prevention of Leaks The combination of sealing and locking ensures a leak-free operation, which is crucial in many industrial applications, thus improving safety and efficiency.

3. Adaptability Locking gaskets are available in a variety of materials and designs, allowing for tailored solutions that meet specific environmental and operational requirements.

4. Longer Service Life By preventing common issues like bolt loosening and gasket failure, these components contribute to a longer service life for both the gaskets and the equipment they protect.

Conclusion

Locking gaskets are vital to modern mechanical engineering, providing essential functions in sealing and bolt security. Their diverse applications in industries such as automotive, aerospace, oil and gas, and marine demonstrate their versatility and importance in maintaining the integrity and safety of machinery. As technology progresses, the development of advanced locking gasket designs will continue to support the need for efficient and reliable systems in an increasingly demanding industrial landscape. Understanding their properties and applications is crucial for engineers and technicians who strive to ensure optimal performance in their operations.