9 月 . 06, 2024 08:22 Back to list

Mechanical Gaskets

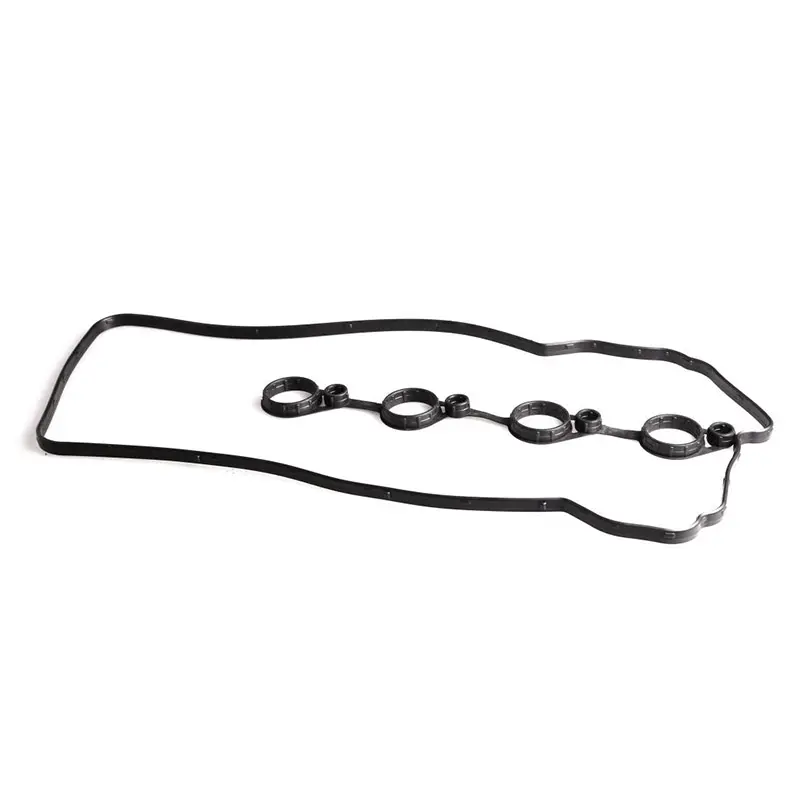

Understanding Mechanical Gaskets Essential Components for Sealing Applications

Mechanical gaskets are critical components widely used in various industries to ensure efficient sealing in mechanical assemblies. These components prevent leakage of fluids, gases, and other substances between different parts of machinery and equipment. Their importance cannot be overstated, as they contribute significantly to the safety, reliability, and efficiency of mechanical systems.

At the core of a mechanical gasket's function is its ability to create a barrier that resists the escape or ingress of substances. This barrier is achieved through the gasket's material properties and design, which allow it to conform to the surfaces it is sealing. The choice of material is crucial, as it must withstand the operating conditions, including temperature, pressure, and the chemical nature of the substances involved. Common materials for gaskets include rubber, silicone, cork, metal, and various composite materials, each offering unique advantages depending on the application.

Mechanical gaskets come in various shapes and sizes, tailored to fit the specific needs of different applications. They can be found in everything from automotive engines and industrial machinery to HVAC systems and plumbing fixtures. Their versatility enables them to provide effective sealing in both static and dynamic applications, where they can accommodate movement and fluctuations in pressure.

mechanical gasket

One of the significant challenges with mechanical gaskets is ensuring that they maintain their sealing capabilities over time. Factors such as wear and tear, chemical degradation, and thermal cycling can lead to gasket failure. To mitigate these risks, regular maintenance and inspections are crucial. Many manufacturers have developed advanced gasket materials and designs to enhance durability and resistance to harsh conditions, prolonging service life and reducing the need for frequent replacements.

Additionally, the installation process of mechanical gaskets plays a vital role in their effectiveness. Proper alignment and adequate compression are essential for achieving a reliable seal. Over-compression can lead to damage and premature failure, while under-compression may result in leaks. Therefore, following manufacturer guidelines and employing best practices during installation is paramount.

In conclusion, mechanical gaskets are indispensable components that play a vital role in preventing leaks and ensuring the efficient performance of machinery. By understanding the various types, materials, and installation techniques, industries can optimize their usage and enhance the longevity of their mechanical systems. As technology advances, we can expect further innovations in gasket design and materials, paving the way for even more reliable sealing solutions in the future.