11 月 . 02, 2024 05:06 Back to list

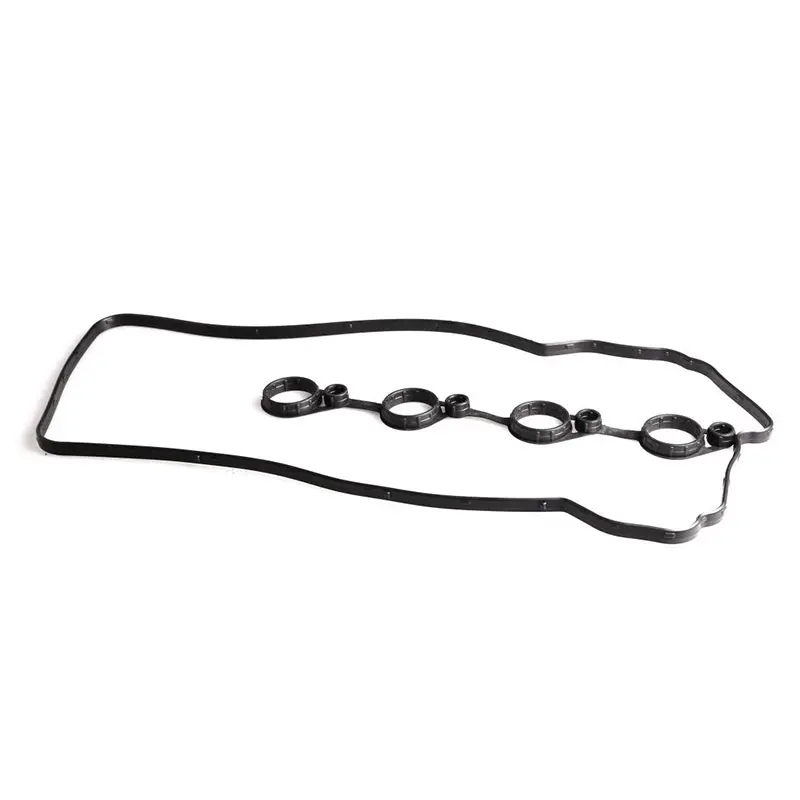

molded gasket

Understanding Molded Gaskets Importance and Applications

Molded gaskets are critical components in various industrial applications, playing a vital role in preventing leaks and maintaining system integrity. These gaskets are manufactured from materials such as rubber, silicone, polyurethane, and other elastomers, which are molded into specific shapes and sizes to fit different equipment and machinery.

One of the main advantages of molded gaskets is their ability to provide a reliable seal under diverse environmental conditions. The manufacturing process allows for precise dimensions and tolerances, ensuring they fit snugly between flanges, covers, or other surfaces. This precision is crucial for applications involving fluids, gases, and pressure, where even the slightest gap can lead to significant leaks and potential equipment failure.

Molded gaskets are used in various industries, including automotive, aerospace, food and beverage, pharmaceuticals, and electronics

. In automotive applications, for instance, they are essential for sealing engine components, oil pans, and transmission cases, thus ensuring optimal performance and longevity. In the food and beverage industry, molded gaskets are critical for maintaining hygiene and preventing contamination, as they can be engineered to meet stringent health and safety standards.molded gasket

The versatility of molded gaskets extends to their customization capabilities. Manufacturers can modify the material compositions and designs to meet specific application requirements, such as temperature extremes, chemical exposure, and flexibility. This adaptability allows industries to utilize molded gaskets in challenging environments, such as high-pressure systems or corrosive settings.

Another important aspect to consider is the installation process. Molded gaskets are designed for easy installation, minimizing downtime during maintenance or assembly. Many modern gaskets include features such as pre-grooved designs or integrated adhesives that simplify the installation process, making them a preferred choice for manufacturers looking to streamline production.

In addition to their functional benefits, molded gaskets contribute to energy efficiency. A properly sealed system minimizes energy losses associated with leaks, leading to better overall efficiency and reduced operational costs. This is particularly important in industries where maintaining pressure or temperature is critical for process control.

Overall, molded gaskets are indispensable in ensuring the reliability and efficiency of machinery across various sectors. Their customized designs, coupled with robust material properties, make them an essential component in preventing leaks and maintaining optimal operational performance. As industries continue to advance, the demand for high-quality molded gaskets will undoubtedly grow, underscoring their significance in modern manufacturing and engineering.