9 月 . 13, 2024 14:49 Back to list

高品质氯丁橡胶法兰垫圈 | 耐高温密封解决方案

Neoprene Flange Gasket A Comprehensive Overview

Neoprene flange gaskets are critical components used in various industrial applications to create a tight seal between flanged joints. Made from neoprene rubber, these gaskets are known for their excellent resistance to oil, chemicals, and weathering, making them ideal for both indoor and outdoor use. This article delves into the properties, applications, and advantages of neoprene flange gaskets.

Properties of Neoprene Flange Gaskets

One of the standout features of neoprene is its versatility. It possesses good mechanical strength and is resistant to a wide range of temperatures, typically ranging from -40°F to 200°F (-40°C to 93°C). This thermal stability ensures that neoprene gaskets maintain their integrity under fluctuating environmental conditions. Additionally, neoprene gaskets are also resistant to the effects of ozone and ultraviolet light, which further enhances their durability and longevity, especially in applications exposed to the elements.

Another important property of neoprene is its ability to provide excellent cushioning and vibration dampening. This makes neoprene flange gaskets ideal for applications where equipment may experience significant movement or vibration, thus preventing leaks and material fatigue.

Applications of Neoprene Flange Gaskets

Neoprene flange gaskets find their use in a wide array of industries including automotive, marine, HVAC (Heating, Ventilation, and Air Conditioning), plumbing, and even food processing. In the automotive sector, these gaskets are often utilized in engine components and fuel systems to prevent leaks and enhance performance. In marine applications, they provide a reliable seal for various fittings, ensuring that water cannot infiltrate critical systems.

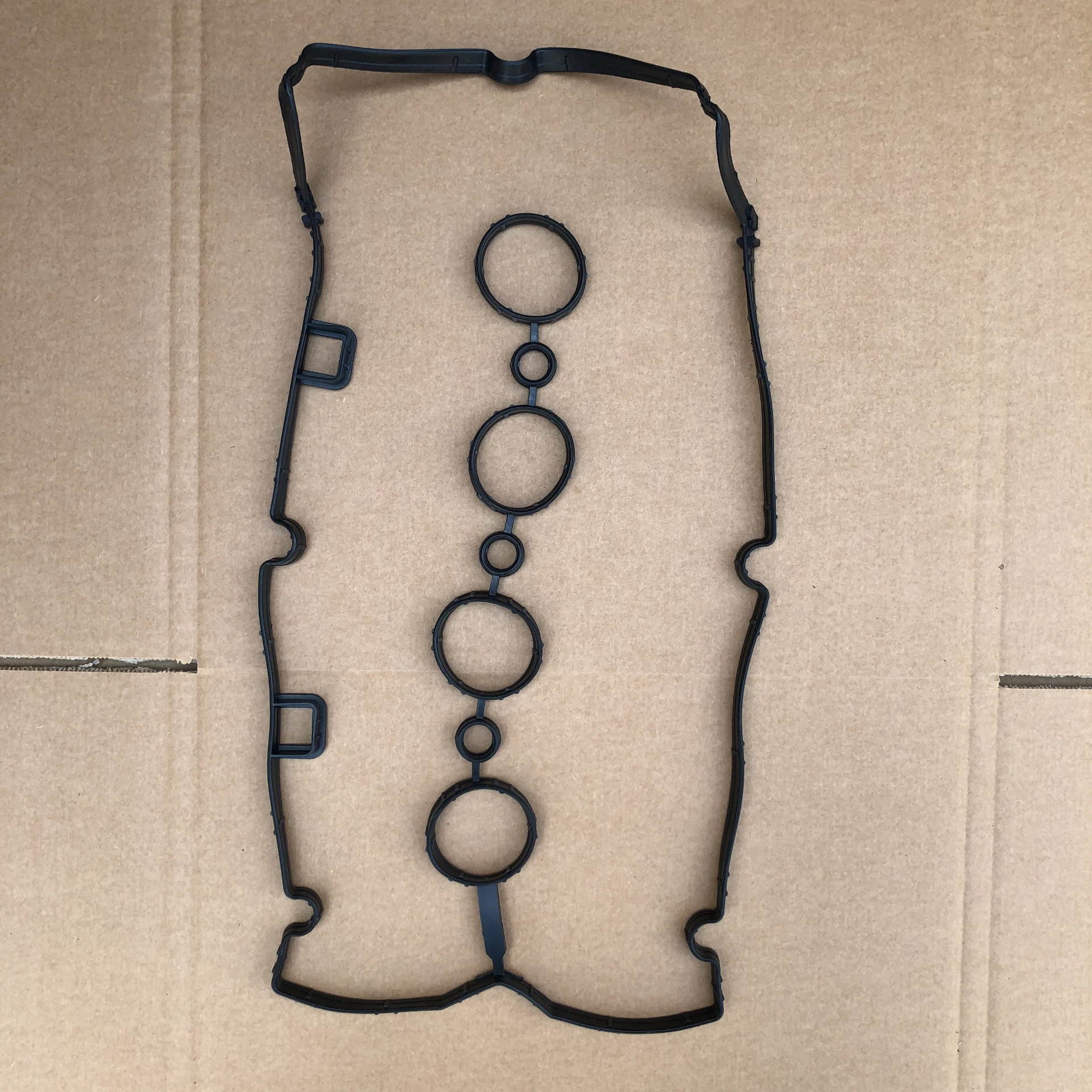

neoprene flange gasket

In HVAC systems, neoprene flange gaskets are commonly used to seal ducts and piping to prevent air leaks, which can lead to energy inefficiency. In plumbing, their resistance to water and chemicals makes them a preferred choice for sealing joints in pipes. Furthermore, in food processing environments, neoprene gaskets can withstand various cleaning chemicals, ensuring compliance with hygiene standards.

Advantages of Neoprene Flange Gaskets

The advantages of using neoprene flange gaskets are numerous. Firstly, their exceptional sealing capabilities reduce the risk of leaks, which can cause significant operational issues and increase maintenance costs. Secondly, the durability of neoprene contributes to lower replacement frequency, leading to cost savings over time. Additionally, the ease of installation associated with neoprene gaskets minimizes downtime during maintenance procedures.

Environmentally, neoprene’s resistance to degradation means that products made with these gaskets can have a longer lifespan, reducing waste and the need for frequent replacements. This aligns well with sustainability goals in various industries.

Conclusion

In conclusion, neoprene flange gaskets serve an essential role in ensuring the reliability and efficiency of numerous applications across multiple industries. Their unique properties, including temperature resistance, chemical stability, and durability, make them a preferred choice for engineers and maintenance professionals alike. As industries continue to evolve, the demand for robust sealing solutions will ensure that neoprene flange gaskets remain a staple in the manufacturing and maintenance of critical systems. Whether for automotive, marine, HVAC, or plumbing applications, neoprene gaskets are designed to meet the challenges of modern engineering and uphold the standards of performance and safety.