10 月 . 31, 2024 02:39 Back to list

oil seal 12 20 5

Understanding Oil Seals The Case of the 12 20 5 Seal

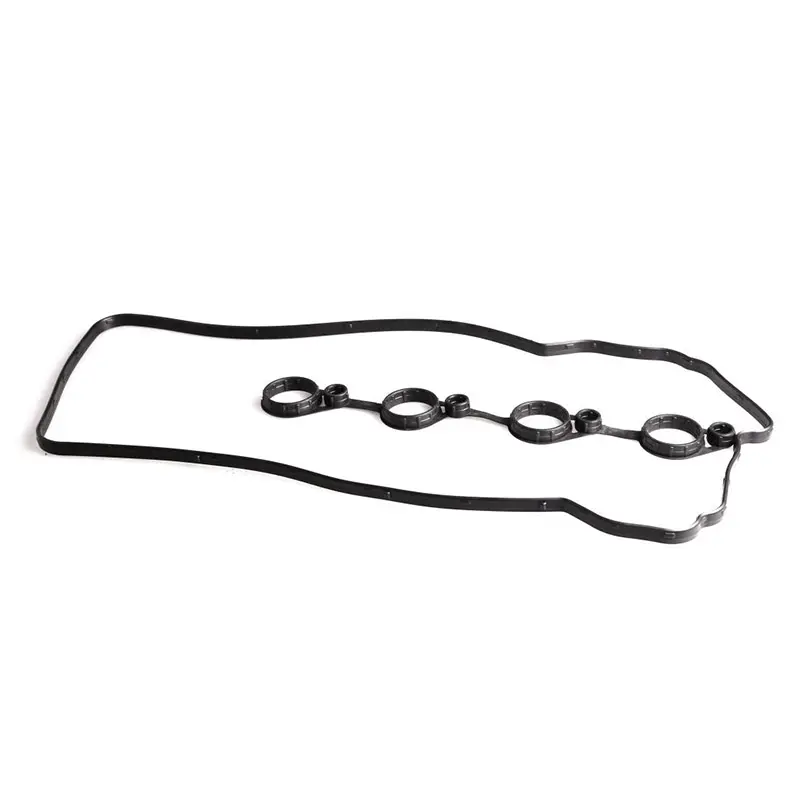

Oil seals, often overlooked, are critical components in a range of machinery and automotive applications. Among these, the oil seal labeled 12 20 5 stands out due to its unique dimensions and specifications. Understanding its purpose, construction, and applications can provide valuable insights into its significance in ensuring the smooth operation of various systems.

What is an Oil Seal?

An oil seal, also known as a lip seal or oil retainer, is designed to prevent the leakage of lubricants while also keeping contaminants out of rotating shafts. It is typically made from materials like rubber, which possess excellent elasticity and resistance to adverse environmental conditions. The basic structure consists of a cylindrical body with a flexible lip that creates a tight seal against a rotating shaft, thereby ensuring effective sealing.

The Specifications of 12 20 5 Oil Seal

The designation 12 20 5 refers to the specific dimensions of the oil seal the first number (12) indicates the inner diameter in millimeters, the second number (20) specifies the outer diameter, and the third number (5) represents the width of the seal. This particular size is commonly used in various applications, making it an integral part of the machinery that keeps industry running smoothly.

oil seal 12 20 5

Importance in Various Applications

Oil seals like the 12 20 5 are widely used in automotive engines, industrial machines, and other mechanical devices. In vehicles, for instance, these seals are often found in the crankshaft and transmission systems, where they play a vital role in preventing oil leaks that can lead to catastrophic engine damage if left unchecked. In industrial applications, similar seals are used to ensure that machinery operates efficiently, minimizing wear and tear on components while maximizing performance and lifespan.

Material Selection and Durability

The longevity and effectiveness of an oil seal heavily depend on the materials used in its construction. Most oil seals are made from synthetic rubber compounds, which offer high resistance to heat, oil, and various chemicals. This durability is crucial, as these seals are often subjected to extreme conditions, including varying temperatures and pressures. Regular maintenance and timely replacement of seals like the 12 20 5 can prevent significant equipment failures, saving both time and money in the long run.

Conclusion

In summary, the oil seal 12 20 5 is a prime example of a small yet vital component in the machinery of modern industry and transportation. Its ability to prevent fluid leaks and keep contaminants at bay makes it indispensable in ensuring operational efficiency and longevity of equipment. Understanding the role and significance of oil seals not only highlights the importance of these components but also underscores the intricate interplay within mechanical systems. Investing in quality oil seals and adhering to regular maintenance schedules is essential for anyone looking to optimize the performance and reliability of their machinery.