2 月 . 15, 2025 10:49 Back to list

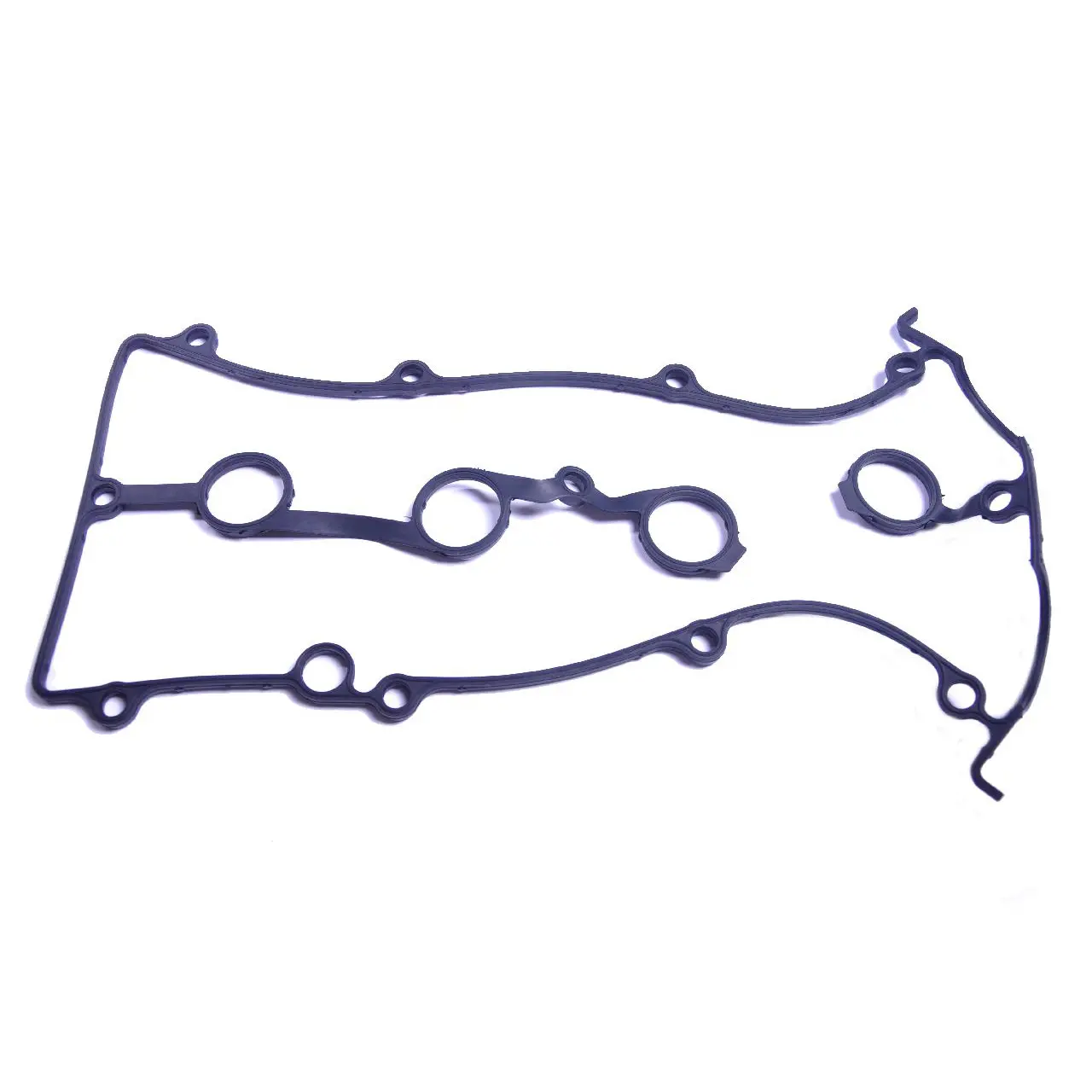

oil seal 12 22 7

Understanding the importance of oil seals in machinery maintenance, especially the model oil seal 12 22 7, requires depth in both expertise and practical experience. Renowned for their indispensable role in safeguarding machinery longevity, oil seals perform the critical function of preventing lubricant leakage while simultaneously warding off harmful contaminants. Let's delve into the world of oil seals with a focus on the oil seal 12 22 7, emphasizing its specific applications, benefits, and installation insights.

For machinery operators and technicians, understanding the signs of a failing oil seal is essential to prevent downtime. Symptoms include lubricant leaks, unusual noise, and increased friction leading to excessive heat generation. Regular inspections can preempt these issues, allowing for timely replacements before significant damage occurs. An essential aspect of expertise in this field is staying up-to-date with the latest advancements in seal technology. Modern oil seals like the oil seal 12 22 7 are engineered to accommodate higher speeds and pressures, offering improved durability and efficiency. Emerging technologies are focusing on enhancing materials and design to further improve sealing efficiency and environmental impact. The reliability and durability of oil seals are often backed by extensive research and testing from trusted manufacturers. It's imperative to source these components from reputable suppliers who provide detailed product data sheets and technical support. This transparency and support establish trustworthiness and ensure that the right product choices contribute to efficient machinery operation. Investing in high-quality oil seals ultimately leads to significant cost savings and operational efficiency. By preventing lubricant leakage and exclusion of contaminants, oil seals help achieve a more sustainable operational environment, contributing positively to energy efficiency and reducing environmental impacts. In conclusion, the oil seal model 12 22 7 stands out due to its adaptability across different applications and environments. Its role in maintaining machinery integrity underscores the importance of choosing the right specifications tailored to specific operational needs. With expert knowledge and proper maintenance, oil seals significantly enhance machinery performance and longevity, demonstrating their indispensability in modern industrial applications.

For machinery operators and technicians, understanding the signs of a failing oil seal is essential to prevent downtime. Symptoms include lubricant leaks, unusual noise, and increased friction leading to excessive heat generation. Regular inspections can preempt these issues, allowing for timely replacements before significant damage occurs. An essential aspect of expertise in this field is staying up-to-date with the latest advancements in seal technology. Modern oil seals like the oil seal 12 22 7 are engineered to accommodate higher speeds and pressures, offering improved durability and efficiency. Emerging technologies are focusing on enhancing materials and design to further improve sealing efficiency and environmental impact. The reliability and durability of oil seals are often backed by extensive research and testing from trusted manufacturers. It's imperative to source these components from reputable suppliers who provide detailed product data sheets and technical support. This transparency and support establish trustworthiness and ensure that the right product choices contribute to efficient machinery operation. Investing in high-quality oil seals ultimately leads to significant cost savings and operational efficiency. By preventing lubricant leakage and exclusion of contaminants, oil seals help achieve a more sustainable operational environment, contributing positively to energy efficiency and reducing environmental impacts. In conclusion, the oil seal model 12 22 7 stands out due to its adaptability across different applications and environments. Its role in maintaining machinery integrity underscores the importance of choosing the right specifications tailored to specific operational needs. With expert knowledge and proper maintenance, oil seals significantly enhance machinery performance and longevity, demonstrating their indispensability in modern industrial applications.

Next: