10 月 . 05, 2024 06:43 Back to list

Replacement Oil Seal 12x20x5 for Enhanced Performance and Durability

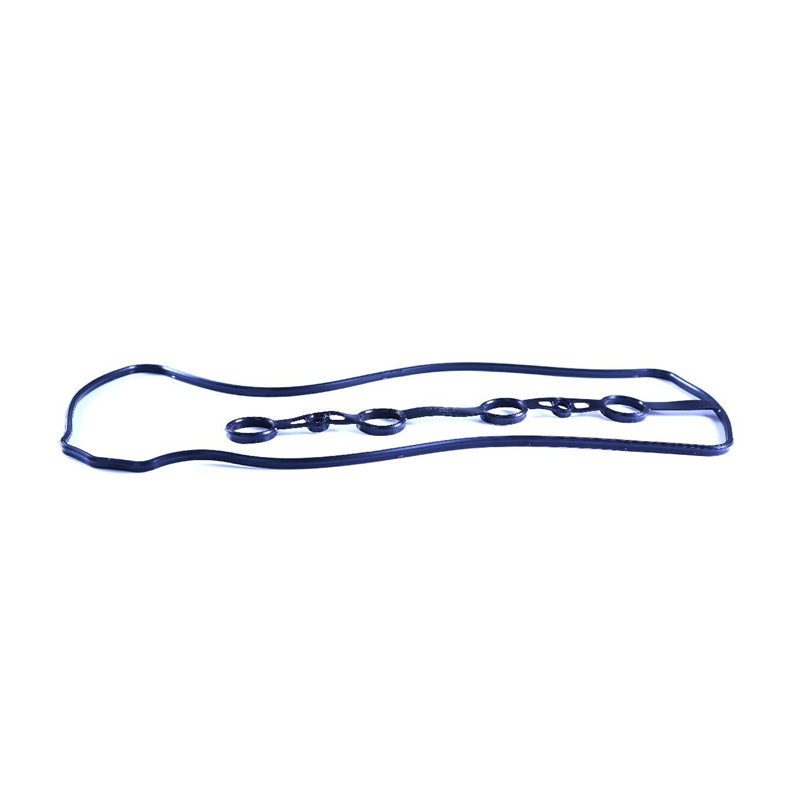

Understanding Oil Seals A Focus on 12x20x5 Oil Seals

Oil seals play a crucial role in various mechanical systems, ensuring the effective containment of lubricants and preventing contaminants from entering the machinery. One specific type of oil seal, identified as 12x20x5, highlights the importance of proper sizing and material selection in maintaining operational efficiency.

Understanding Oil Seals A Focus on 12x20x5 Oil Seals

Materials used in manufacturing oil seals are equally important. Common materials include nitrile rubber (NBR), fluorocarbon (FKM), and polyurethane (PU), each offering unique properties suited for different environments. NBR is widely used for its excellent oil resistance, making it ideal for automotive applications where exposure to lubricants is frequent. On the other hand, FKM provides superior thermal stability and chemical resistance, making it suitable for more demanding environments.

oil seal 12x20x5

The installation process of oil seals also requires careful attention to detail. An improperly installed 12x20x5 oil seal can lead to leaks, reduced lubrication, and even catastrophic failure of machinery. It is essential to ensure that the sealing surface is clean and free of any debris, as contaminants can compromise the seal's effectiveness. Additionally, using the correct tools and techniques during installation will help to create a reliable seal.

Regular maintenance and inspection of oil seals can help prevent costly downtimes. Look for signs of wear, such as cracks or deformation, which may indicate that the oil seal needs replacement. Timely intervention can save significant costs associated with operational disruptions.

In conclusion, understanding the nuances of oil seals, particularly the 12x20x5 variant, is vital for anyone involved in machinery maintenance and assembly. By paying attention to dimensions, materials, installation practices, and maintenance routines, users can ensure optimal performance and longevity of their equipment, ultimately contributing to smoother operations and enhanced productivity.