2 月 . 15, 2025 08:57 Back to list

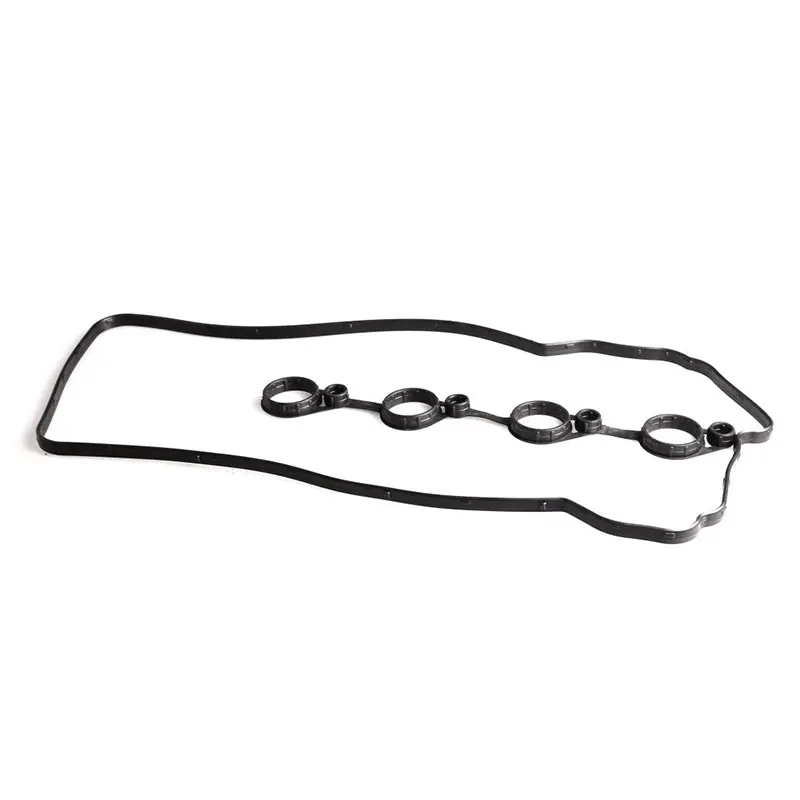

oil seal 15 30 7

The world of mechanical engineering relies heavily on components that, while small, bear immense significance to the efficiency and durability of machinery. One such component is the oil seal, particularly the 15-30-7 oil seal. This seal, categorized by its dimensions (15mm inner diameter, 30mm outer diameter, and 7mm thickness), plays a pivotal role in maintaining the integrity of various mechanical systems. Here's why the 15-30-7 oil seal is indispensable, reflecting deep expertise and authoritative insight.

In addition to its primary functions, the 15-30-7 oil seal contributes significantly to the efficiency of machinery. By minimizing friction between moving parts, it reduces wear and tear, thereby lowering maintenance costs and prolonging the service life of equipment. This reliability is crucial in industries where machinery uptime directly impacts productivity and profitability. From an expert perspective, sourcing the correct 15-30-7 oil seal is vital. Engage with reputable suppliers who provide comprehensive product specifications and quality assurances, a practice that embeds trustworthiness in your procurement process. Reliable suppliers often offer seals that meet international standards, such as ISO or DIN certifications, which serve as a testament to the product's authority and quality. In summary, the oil seal 15-30-7 stands as a testament to engineering excellence, blending precision, durability, and functionality in a small yet powerful package. Its role in safeguarding machinery while enhancing operational efficiency cannot be overstated. Investing time in understanding and selecting the right oil seal aligns with best practices in asset management, affirming the seal's place as an irreplaceable component in the mechanical engineering landscape. As industries evolve, so too will the need for components like the 15-30-7 oil seal, embodying experience, expertise, authoritativeness, and trustworthiness at every turn.

In addition to its primary functions, the 15-30-7 oil seal contributes significantly to the efficiency of machinery. By minimizing friction between moving parts, it reduces wear and tear, thereby lowering maintenance costs and prolonging the service life of equipment. This reliability is crucial in industries where machinery uptime directly impacts productivity and profitability. From an expert perspective, sourcing the correct 15-30-7 oil seal is vital. Engage with reputable suppliers who provide comprehensive product specifications and quality assurances, a practice that embeds trustworthiness in your procurement process. Reliable suppliers often offer seals that meet international standards, such as ISO or DIN certifications, which serve as a testament to the product's authority and quality. In summary, the oil seal 15-30-7 stands as a testament to engineering excellence, blending precision, durability, and functionality in a small yet powerful package. Its role in safeguarding machinery while enhancing operational efficiency cannot be overstated. Investing time in understanding and selecting the right oil seal aligns with best practices in asset management, affirming the seal's place as an irreplaceable component in the mechanical engineering landscape. As industries evolve, so too will the need for components like the 15-30-7 oil seal, embodying experience, expertise, authoritativeness, and trustworthiness at every turn.

Next: