10 月 . 31, 2024 01:58 Back to list

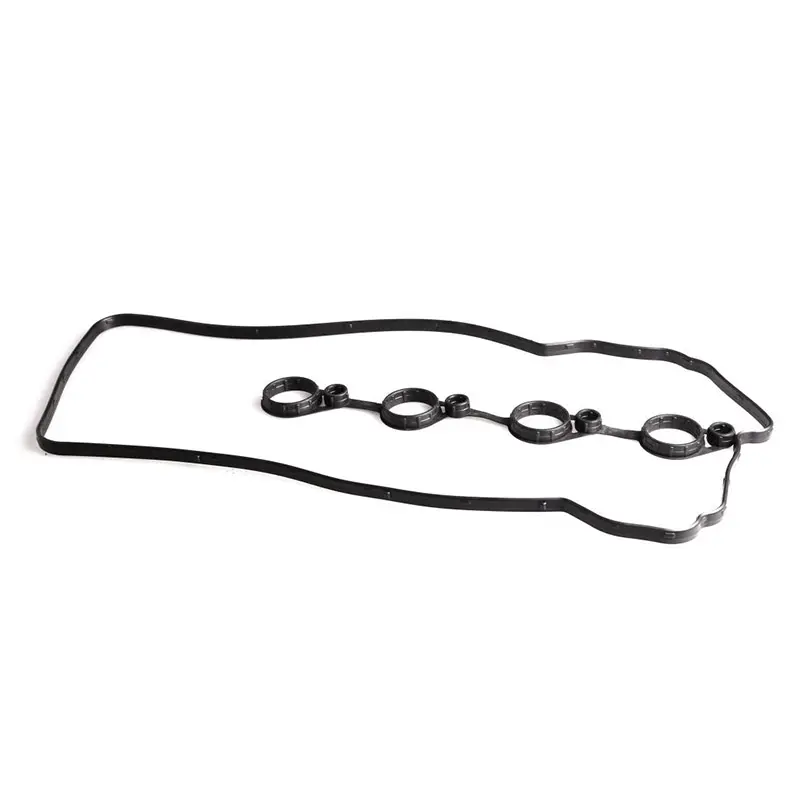

oil seal 22 32 7

Understanding Oil Seals A Closer Look at Oil Seal 22 32 7

Oil seals are critical components in various mechanical systems, serving the primary purpose of preventing lubricant leakage and protecting machinery from contaminants. One particular type, designated by the dimensions 22, 32, and 7, is commonly used across numerous applications, particularly in automotive and industrial machinery.

What Are Oil Seals?

Oil seals, also known as rotating shaft seals or lip seals, are designed to maintain the integrity of a system by sealing the gap between stationary and moving components. They effectively contain lubricants, preventing them from escaping, while simultaneously blocking dust, dirt, and moisture from infiltrating the system. The structure of an oil seal typically consists of two main parts the sealing lip and the outer casing. The sealing lip, often made of elastomers, is the component that makes contact with the shaft, creating a tight seal.

Specifications of Oil Seal 22 32 7

The designation 22 32 7 refers to the dimensions of the oil seal in millimeters a 22 mm inner diameter, a 32 mm outer diameter, and a 7 mm thickness. These specific measurements indicate that this oil seal is intended for applications that require a robust seal to accommodate a shaft with a diameter of 22 mm. The 32 mm outer diameter allows for a secure fit within a housing or bore, while the 7 mm thickness adds structural integrity to the seal, ensuring longevity and durability.

oil seal 22 32 7

Applications

Oil seals with the dimensions 22 32 7 are commonly found in various applications, including automotive gearboxes, engines, agricultural machinery, industrial motors, and hydraulic systems. Their ability to withstand high rotational speeds and pressures makes them an ideal choice for these environments. By preventing the escape of oil and the entry of contaminants, these seals contribute significantly to the efficiency and longevity of the machinery they protect.

Benefits of Using the Right Oil Seal

Selecting the correct oil seal is vital for ensuring optimal performance in any mechanical system. Using the wrong seal can lead to increased wear, oil leaks, and ultimately, system failure. The oil seal 22 32 7 is specifically designed for applications requiring precise sealing capabilities, ensuring that lubricants remain intact and mechanical parts stay protected from harmful external factors.

Conclusion

In summary, oil seals are indispensable components in mechanical systems, with the oil seal 22 32 7 playing a crucial role in maintaining operational efficiency and reliability. Understanding the specifications and applications of this particular oil seal can help engineers and technicians make informed decisions, ensuring the longevity and performance of machinery across various industries. By utilizing the proper seal, one can prevent costly repairs and enhance overall operational efficacy.