1 月 . 20, 2025 04:16 Back to list

Rotary wheel of auto parts

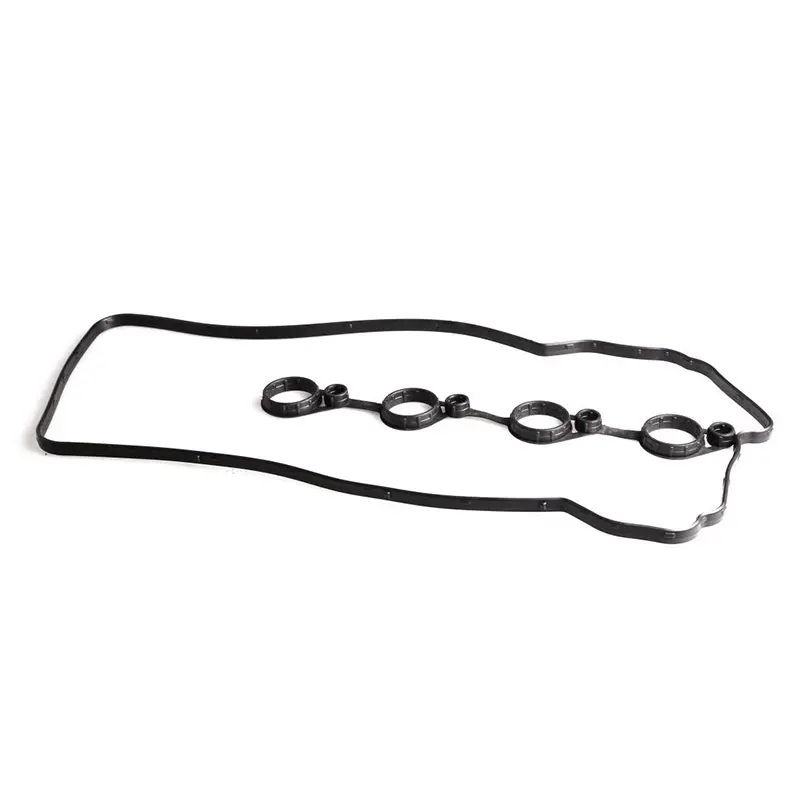

Oil seal 25 35 7 is an essential component in a variety of industrial applications, celebrated for its precision and durability. Designed to ensure a tight seal, it plays a pivotal role in enhancing the performance and longevity of machinery by preventing the ingress of dirt, dust, and foreign contaminants while retaining lubricants within the system. This unique capability makes it indispensable for industries where maintaining operational integrity is crucial.

The seal's reputation is further bolstered by its trustworthiness, as documented by numerous case studies and testimonials. In highly regulated industries, where safety and reliability are non-negotiable, the credibility of using a proven product like oil seal 25 35 7 cannot be overstated. Its consistent performance and adherence to stringent quality standards make it a preferred choice among industry leaders. Expertise in the selection and installation of this oil seal comes from years of experience and technical knowledge. Professionals understand the nuances of its application, knowing that even a small mistake can lead to suboptimal performance or failure. As such, training and experience are invaluable, reinforcing the authority of those who specialize in this crucial component. Trust is cultivated through both empirical evidence and performance analytics, which consistently highlight the oil seal 25 35 7 as a reliable solution. Users and engineers alike report significant improvements in operational efficiency and reduced incidents of leaks or failures. This level of dependability engenders confidence, reinforcing the seal's status as an authoritative component within the sector. Combining cutting-edge material science with practical insights, the oil seal 25 35 7 is not merely a functional component but a symbol of engineering prowess. Its utility continues to evolve as industries demand higher standards of performance and innovation in sealing technology. Each application serves as a testament to the expertise and dedication inherent in its design, bringing peace of mind to those who rely on its unmatched capabilities.

The seal's reputation is further bolstered by its trustworthiness, as documented by numerous case studies and testimonials. In highly regulated industries, where safety and reliability are non-negotiable, the credibility of using a proven product like oil seal 25 35 7 cannot be overstated. Its consistent performance and adherence to stringent quality standards make it a preferred choice among industry leaders. Expertise in the selection and installation of this oil seal comes from years of experience and technical knowledge. Professionals understand the nuances of its application, knowing that even a small mistake can lead to suboptimal performance or failure. As such, training and experience are invaluable, reinforcing the authority of those who specialize in this crucial component. Trust is cultivated through both empirical evidence and performance analytics, which consistently highlight the oil seal 25 35 7 as a reliable solution. Users and engineers alike report significant improvements in operational efficiency and reduced incidents of leaks or failures. This level of dependability engenders confidence, reinforcing the seal's status as an authoritative component within the sector. Combining cutting-edge material science with practical insights, the oil seal 25 35 7 is not merely a functional component but a symbol of engineering prowess. Its utility continues to evolve as industries demand higher standards of performance and innovation in sealing technology. Each application serves as a testament to the expertise and dedication inherent in its design, bringing peace of mind to those who rely on its unmatched capabilities.