2 月 . 15, 2025 00:02 Back to list

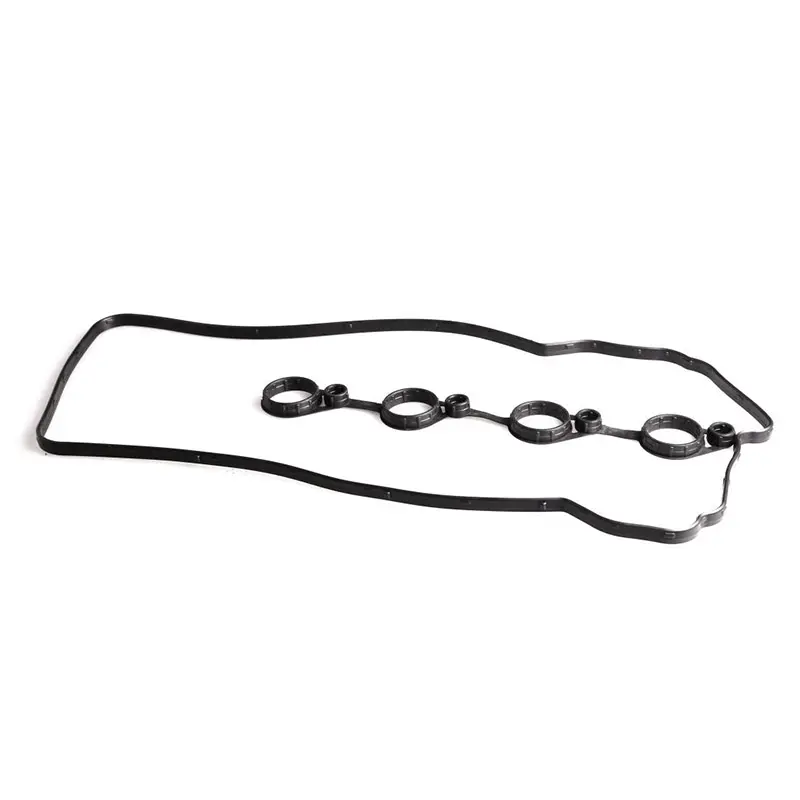

oil seal 50 * 72 * 10

Selecting the right oil seal is crucial for ensuring the longevity and efficiency of machinery components. Among the various options available, the oil seal with dimensions 50 * 72 * 10 stands out as a critical part for many applications. Understanding the specifics of its application, material composition, and effectiveness can greatly enhance its performance and the machinery it supports.

From an authoritative viewpoint, oil seals with dimensions of 50 * 72 * 10 are often referenced in technical manuals and engineering guidelines due to their prevalent use and efficiency. These resources highlight the seal’s versatility in adapting to fluctuating operational demands and its ability to maintain a reliable barrier across dynamic and static sealing interfaces. Companies producing these seals undergo rigorous testing and adhere to strict industry standards, further substantiating their reliability and performance. Trustworthiness hinges on choosing products from reputable manufacturers known for their commitment to quality and innovation. Certifications like ISO 9001 and industry-specific approvals confirm that the oil seal meets the expected regulatory and safety standards. Incorporating genuine 50 * 72 * 10 oil seals into your equipment ensures reduced maintenance costs and downtime. Regular inspections and replacements, aligned with manufacturer guidelines, bolster the machinery's operational efficacy and longevity. With growing challenges and demands in mechanical applications, ensuring that such components are optimized for performance and reliability is not merely advisable, it is essential. Investing in high-quality oil seals is a strategic choice that pays dividends through enhanced machine life, reduced environmental impact, and improved operator safety. In summary, the 50 * 72 * 10 oil seal is more than a mechanical component. It is a vital part of a broader system that upholds operational integrity. Experts in the field recognize it as a linchpin for system efficiency, and the choice of materials and partners in its manufacturing and supply chain is critical for delivering optimal performance and reliability.

From an authoritative viewpoint, oil seals with dimensions of 50 * 72 * 10 are often referenced in technical manuals and engineering guidelines due to their prevalent use and efficiency. These resources highlight the seal’s versatility in adapting to fluctuating operational demands and its ability to maintain a reliable barrier across dynamic and static sealing interfaces. Companies producing these seals undergo rigorous testing and adhere to strict industry standards, further substantiating their reliability and performance. Trustworthiness hinges on choosing products from reputable manufacturers known for their commitment to quality and innovation. Certifications like ISO 9001 and industry-specific approvals confirm that the oil seal meets the expected regulatory and safety standards. Incorporating genuine 50 * 72 * 10 oil seals into your equipment ensures reduced maintenance costs and downtime. Regular inspections and replacements, aligned with manufacturer guidelines, bolster the machinery's operational efficacy and longevity. With growing challenges and demands in mechanical applications, ensuring that such components are optimized for performance and reliability is not merely advisable, it is essential. Investing in high-quality oil seals is a strategic choice that pays dividends through enhanced machine life, reduced environmental impact, and improved operator safety. In summary, the 50 * 72 * 10 oil seal is more than a mechanical component. It is a vital part of a broader system that upholds operational integrity. Experts in the field recognize it as a linchpin for system efficiency, and the choice of materials and partners in its manufacturing and supply chain is critical for delivering optimal performance and reliability.

Next: