10 月 . 04, 2024 05:33 Back to list

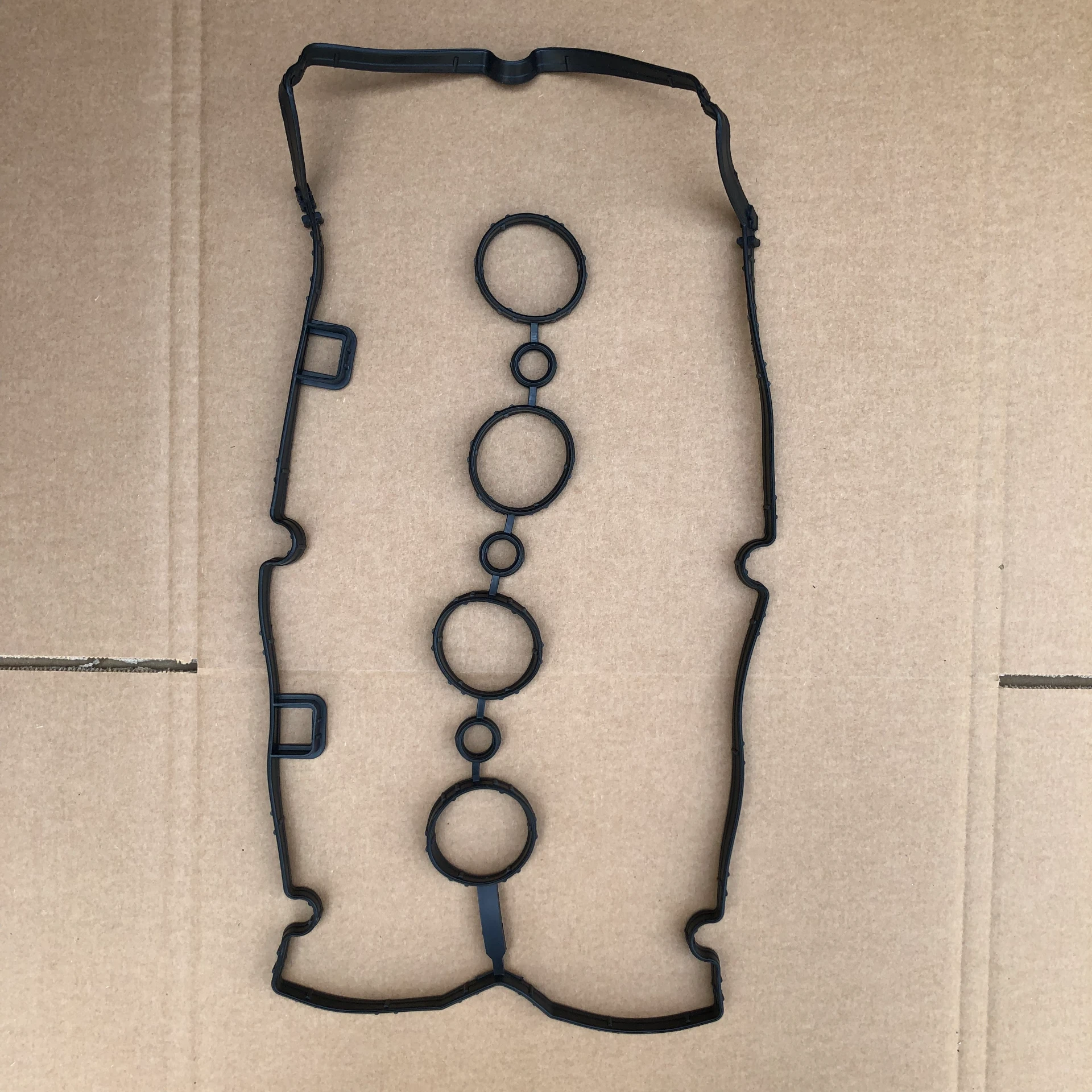

oil seal in motor

Understanding Oil Seals in Motors

Oil seals play a crucial role in the efficient functioning of motors, whether in industrial applications, automobiles, or household appliances. These components are designed to prevent the leakage of lubricating oil from the engine or motor, thus ensuring optimal performance and longevity of the machinery.

Understanding Oil Seals in Motors

The importance of oil seals in motors cannot be overstated. Without a proper seal, lubricants can escape, leading to increased friction and wear on the moving parts. This can result in overheating and eventual failure of the motor. Furthermore, contaminants can enter the motor, which can corrode internal components and significantly shorten the lifespan of the equipment. An effective oil seal helps to maintain the integrity of the lubrication system, allowing the motor to operate smoothly and efficiently.

oil seal in motor

There are various types of oil seals, each suited for specific applications. For example, radial lip oil seals are designed to handle high-speed rotations, making them ideal for automotive engines. On the other hand, axial seals are used in applications where space is limited and axial loads are prevalent. The choice of oil seal is critical, as it must accommodate the temperature, pressure, and chemical environment of the application.

Installation of oil seals also requires careful attention. They must be fitted correctly to prevent leakage and ensure a long service life. Improper installation can lead to misalignment, which can cause premature wear. Regular inspection and maintenance of oil seals are vital to avoid costly repairs and downtime. It is recommended to replace oil seals during routine maintenance checks, particularly in high-wear applications.

Advancements in material science have led to the development of high-performance oil seals that can resist extreme temperatures and aggressive chemicals. This has broadened the scope of applications, making them suitable for use in modern electric motors and hybrid vehicles. As industries continue to evolve, the importance of reliable sealing solutions becomes increasingly paramount in ensuring the longevity and efficiency of mechanical systems.

In conclusion, oil seals are essential components that contribute significantly to the functionality and durability of motors. Their role in preventing oil leakage and protecting against contaminants is critical for maintaining performance and reducing maintenance costs. Whether in automotive, industrial, or consumer applications, investing in high-quality oil seals and proper maintenance practices is vital for ensuring the reliable operation of motor systems.