1 月 . 15, 2025 09:09 Back to list

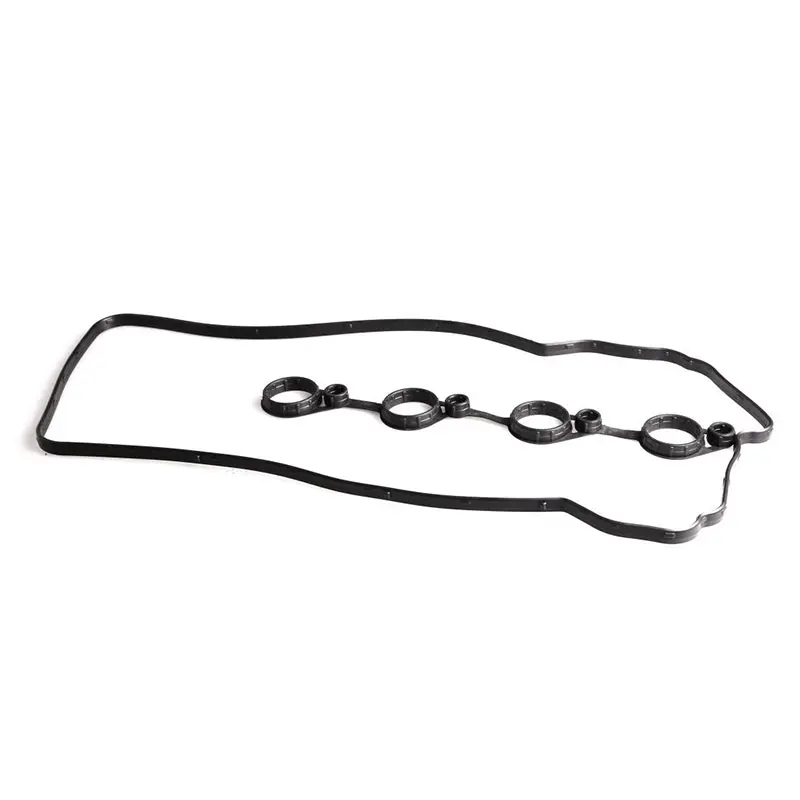

oil seal rubber part

Navigating the intricate world of oil seal rubber parts requires a blend of professional expertise and real-world experience to ensure optimal machinery performance. These components, often underestimated in terms of their critical role, serve as a guardian, protecting against the ingress of dirt and the egress of lubricants and fluids. Understanding their importance is pivotal for anyone involved in industrial maintenance or machinery repair.

Trustworthiness in the manufacturing and supply of oil seal rubber parts is another critical factor. Reputable manufacturers should adhere to stringent quality control standards and provide assurance of material consistency and performance reliability. Certifications and accreditations serve as a benchmark of quality and add a layer of trust, assuring clients that their equipment will not be compromised by substandard components. Real-world testimonials and case studies further reinforce the credibility of these products. Sharing experiences from clients where oil seal failures were effectively mitigated or prevented through the use of superior quality seals can bolster trust. These narratives underscore not only the product effectiveness but also highlight the expertise of the suppliers and technicians involved. To maintain a seal’s integrity, regular inspection and maintenance are essential. Experienced professionals advocate for routine checks and timely replacements as proactive practices to avert potential failures. This not only ensures machinery operates at peak performance but also extends the lifespan of the equipment. In essence, oil seal rubber parts are small yet mighty components of industrial machinery. Their selection and application, backed by professional expertise and trusted manufacturing processes, play a significant role in enhancing machinery performance and reliability. By focusing on these elements, businesses can ensure they remain operationally efficient, avoiding the pitfalls of unexpected breakdowns and costly repairs.

Trustworthiness in the manufacturing and supply of oil seal rubber parts is another critical factor. Reputable manufacturers should adhere to stringent quality control standards and provide assurance of material consistency and performance reliability. Certifications and accreditations serve as a benchmark of quality and add a layer of trust, assuring clients that their equipment will not be compromised by substandard components. Real-world testimonials and case studies further reinforce the credibility of these products. Sharing experiences from clients where oil seal failures were effectively mitigated or prevented through the use of superior quality seals can bolster trust. These narratives underscore not only the product effectiveness but also highlight the expertise of the suppliers and technicians involved. To maintain a seal’s integrity, regular inspection and maintenance are essential. Experienced professionals advocate for routine checks and timely replacements as proactive practices to avert potential failures. This not only ensures machinery operates at peak performance but also extends the lifespan of the equipment. In essence, oil seal rubber parts are small yet mighty components of industrial machinery. Their selection and application, backed by professional expertise and trusted manufacturing processes, play a significant role in enhancing machinery performance and reliability. By focusing on these elements, businesses can ensure they remain operationally efficient, avoiding the pitfalls of unexpected breakdowns and costly repairs.

Next: