1 月 . 07, 2025 10:12 Back to list

oil seals for sale

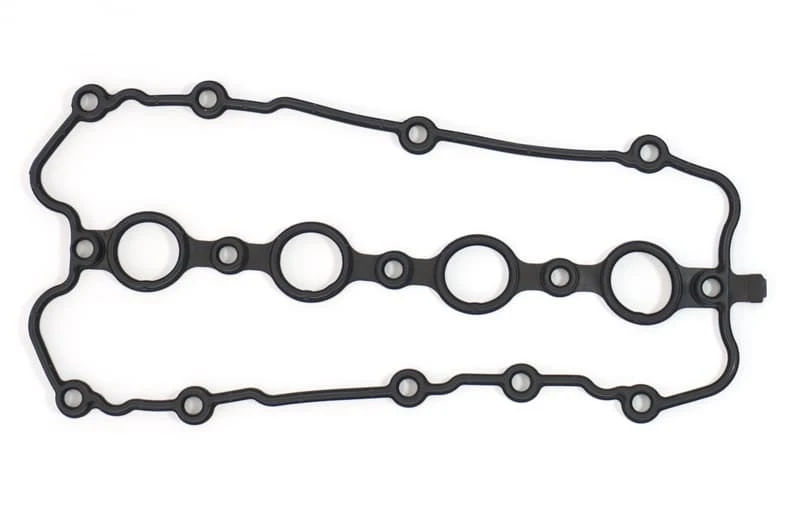

Finding the ideal oil seals for sale requires a discerning eye and an understanding of the nuanced needs of various machinery. The significance of choosing the right oil seals cannot be overstated, as they play a pivotal role in enhancing equipment efficiency, prolonging lifespan, and maintaining optimal functionality. Through experience and expertise, one gains clarity on selecting seals that guarantee peak performance even under challenging conditions.

Oil seals, technically known as radial shaft seals, serve an essential purpose in preventing the leakage of lubricants. At the same time, they keep contaminants from entering the machinery. In my decades of accumulated knowledge and hands-on interaction with diverse mechanical systems, I've witnessed firsthand the intricate balance these seals maintain. Selecting subpar oil seals can lead to dire consequences, manifesting in mechanical failures, costly downtime, and unexpected maintenance bills.

When evaluating oil seals for sale, it's imperative to assess the material. Different applications call for seals made from specified materials such as nitrile rubber, fluorocarbon, or silicone. For example, fluorocarbon seals excel at enduring high temperatures and are resistant to a variety of chemicals, making them ideal for more demanding environments. Nitrile rubber, on the other hand, is often chosen for its robust resistance to wear and tear, along with its cost-effectiveness for everyday applications.

In the pursuit of finding authoritative sources, always prioritize suppliers with a proven legacy of reliability and authenticity. The most trustworthy sellers provide detailed product specifications, alongside certifications that vouch for their quality compliance and manufacturing standards. As a professional in the field, I advocate for engaging with companies that have a robust support system, offering expert consultations to guide one’s purchase decisions.

oil seals for sale

In today’s digital marketplace, the availability of oil seals is vast. Therefore, practical experience suggests scrutinizing customer reviews and testimonials as an indicator of the product's real-world performance. Legitimate reviews furnish valuable insights into post-purchase experiences, revealing any potential issues that might not be immediately apparent through product descriptions and technical data.

Another critical component in evaluating oil seals is the precision of dimensioning. A seal that fits perfectly is essential to ensure it functions as intended. Misfit seals are notorious for exacerbating wear and can sometimes elevate energy consumption due to friction. Always cross-reference the dimensions listed with the standard sizes such as shaft diameter, bore diameter, and the seal width to alleviate chances of mismatch.

In an age where counterfeit products proliferate, safeguarding one's purchases is non-negotiable. Rely on suppliers who assure genuine branding and offer warranties or guarantees. This not only fortifies trust but also protects one's investment in quality products. Moreover, it aligns with the broader ethos of sustainability, championing longevity over disposable components.

To conclude, embarking on the journey of acquiring oil seals is more than a transaction; it's an investment in operational integrity. By invoking an ethos of experience and expertise, supported by authoritative and trustworthy practices, clients are empowered not merely to buy but to ensure their machinery's longevity and efficiency. This choice reaffirms one's commitment to quality and underscores the imperative of informed decision-making in the realm of mechanical maintenance.