10 月 . 21, 2024 20:38 Back to list

Understanding the Importance of Positive Oil Seals in Mechanical Systems

Understanding POS Oil Seals Essential Components for Mechanical Systems

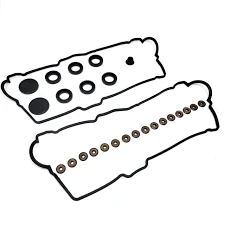

In the realm of mechanical engineering, oil seals are vital components designed to prevent the leakage of lubricants and protect machinery from contaminants. Among various oil seals available, the POS oil seal stands out due to its unique characteristics and versatile applications. This article delves into the significance, features, advantages, and applications of POS oil seals, providing a comprehensive overview for engineers, technicians, and manufacturers in the field.

What is a POS Oil Seal?

A POS oil seal is a type of oil seal that is commonly used in rotating equipment to seal the interface between moving and stationary parts. The acronym “POS” can denote a specific design or manufacturer, but in both cases, these seals are engineered to meet high-performance standards. Typically made from high-quality elastomeric materials, POS oil seals are capable of withstanding extreme temperatures, pressures, and chemical exposures, ensuring a reliable seal in various environments.

Key Features of POS Oil Seals

1. Material Composition POS oil seals are crafted from advanced polymer materials such as nitrile rubber (NBR), fluorocarbon (FKM), or polyurethane (PU). These materials are selected based on their resilience to thermal degradation, mechanical wear, and chemical resistance.

2. Design Considerations POS oil seals are designed with precise specifications to ensure optimal sealing performance. They often feature a lip that creates a hydrodynamic film, preventing oil spills and permitting the smooth operation of rotating components.

3. Versatility One of the standout features of POS oil seals is their adaptability across various applications. They can be found in automotive, industrial machinery, aerospace, and even domestic appliances. This versatility makes them indispensable in modern engineering.

4. Customizability Manufacturers often offer POS oil seals in various sizes and configurations, enabling businesses to customize solutions that fit their specific requirements. This flexibility ensures that engineers can select the perfect seal for their particular machinery.

Advantages of Using POS Oil Seals

pos oil seal

1. Leak Prevention The primary function of POS oil seals is to prevent lubricant leaks. By effectively containing oils and greases within machines, they help maintain optimal performance and reduce maintenance costs.

2. Contaminant Protection These seals prevent dirt, dust, and other contaminants from entering critical components. This protective barrier significantly extends the life of machinery by minimizing wear and tear caused by external particles.

3. Energy Efficiency By ensuring proper lubrication and preventing leaks, POS oil seals contribute to energy efficiency in machinery. This enhancement not only lowers operational costs but also promotes sustainable practices in manufacturing.

4. Longevity and Reliability The robust design and high-quality materials used in POS oil seals contribute to their long lifespan. Reliable performance reduces the likelihood of machinery failure, ensuring uninterrupted operations in production environments.

Applications of POS Oil Seals

POS oil seals have extensive applications across various industries

- Automotive Industry Used in engines, transmissions, and differential assemblies, ensuring optimal lubricant retention and reducing the risk of component failure. - Industrial Equipment Found in pumps, compressors, and gearboxes, these seals help maintain proper lubrication in heavy-duty machinery. - Aerospace Applications POS oil seals are utilized in aircraft engines and hydraulic systems, where reliability and performance are critical. - Household Appliances Used in washing machines, refrigerators, and HVAC systems, promoting energy efficiency and preventing leaks.

Conclusion

In summary, POS oil seals play an indispensable role in the realm of mechanical systems. Their ability to prevent lubricant leaks, protect machinery from contaminants, and enhance energy efficiency makes them a crucial component in various industries. With their diverse applications and reliable performance, POS oil seals represent a perfect amalgamation of innovation and engineering. For engineers and manufacturers, understanding the mechanics and benefits of these seals is essential for achieving optimal performance in their respective fields. As technology advances, the demand for high-quality oil seals like POS will inevitably continue to grow, paving the way for even more innovative sealing solutions in the future.