10 月 . 16, 2024 18:06 Back to list

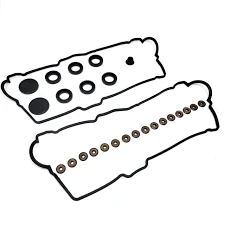

Round and Flat Rubber Gaskets for Various Industrial Applications and Sealing Solutions

The Essential Guide to Round Flat Rubber Gaskets

In the world of engineering and manufacturing, the importance of sealing solutions cannot be overstated. Among the myriad of sealing components available, round flat rubber gaskets stand out as a highly effective solution for various applications. These gaskets not only offer excellent sealing capabilities but also bring a range of advantages that make them suitable for diverse industries.

What is a Round Flat Rubber Gasket?

A round flat rubber gasket is a circular sealing component made from rubber or elastomers. This type of gasket is designed to fill the space between two or more surfaces to prevent leakage or the ingress of dirt, moisture, and other contaminants. The flat design allows for even distribution of pressure when compressed between mating surfaces, ensuring a tight seal.

Material Composition

The choice of material is crucial when selecting a round flat rubber gasket. Common materials used in the manufacturing of these gaskets include neoprene, nitrile, silicone, and EPDM (ethylene propylene diene monomer). Each material has its own unique properties, making it suitable for specific applications. For instance, silicone gaskets are popular in high-temperature applications, while nitrile gaskets are preferred for fuel and oil resistance.

Applications of Round Flat Rubber Gaskets

Round flat rubber gaskets are widely utilized across various sectors, including

1. Automotive Industry Gaskets are pivotal in engine components, fuel tanks, and exhaust systems, where they provide a reliable seal against oil and fuel leakage. 2. Aerospace In aviation applications, these gaskets play a critical role in sealing hydraulic systems and fuel tanks, ensuring safety and functionality under extreme conditions.

3. Construction Round flat rubber gaskets are commonly used in plumbing and HVAC systems to prevent leaks and ensure efficient operation.

round flat rubber gasket

4. Industrial Machinery They are found in various machinery and equipment, where they provide sealing solutions for pumps, compressors, and valves.

5. Electrical Applications Gaskets help seal electrical enclosures against moisture and dust, safeguarding sensitive components.

Benefits of Using Round Flat Rubber Gaskets

1. Versatility With a variety of materials and thicknesses available, round flat rubber gaskets can be customized to meet specific sealing requirements, making them suitable for a wide range of applications.

2. Cost-Effectiveness Compared to metal or other sealing solutions, rubber gaskets are often more economical. Their durability reduces the need for frequent replacements, resulting in long-term savings.

3. Easy Installation The lightweight nature and flexibility of rubber gaskets make them easy to handle and install, streamlining the assembly process.

4. Chemical Resistance Depending on the material chosen, these gaskets can withstand various chemicals, oils, and temperatures, which is critical in environments prone to chemical exposure.

5. Compression Set Resistance Quality rubber gaskets have excellent compression set resistance, meaning they maintain their shape and sealing capability even after prolonged compression.

Conclusion

Round flat rubber gaskets are an indispensable part of modern engineering and manufacturing. Their ability to provide reliable sealing solutions across various industries is a testament to their importance. When selecting the right gasket, it is essential to consider the material and application requirements to ensure optimal performance. As technology advances, the future will likely see even more innovative gasket solutions, further solidifying the role of round flat rubber gaskets in achieving efficiency and reliability in various applications.