2 月 . 06, 2025 06:25 Back to list

Rotary wheel of auto parts

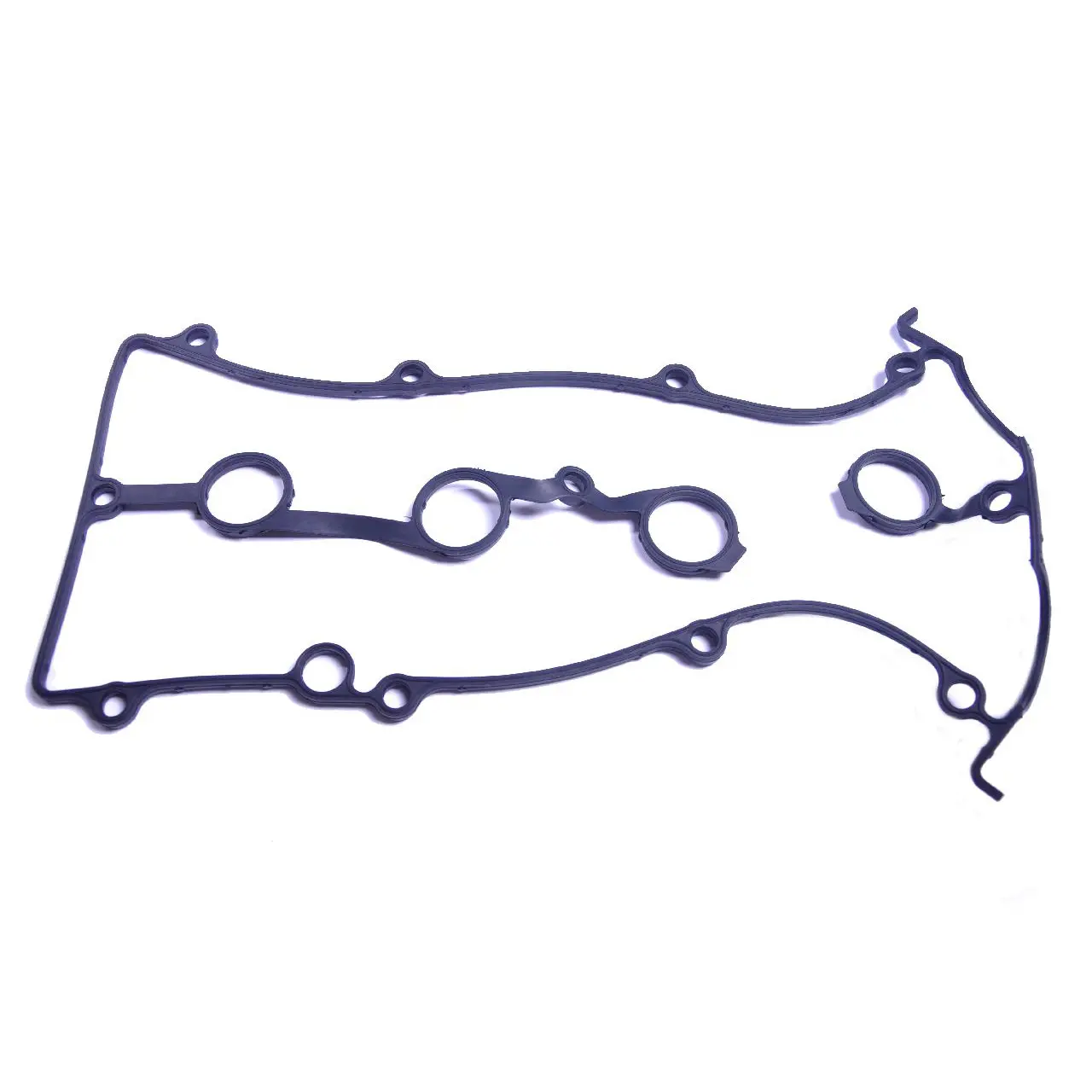

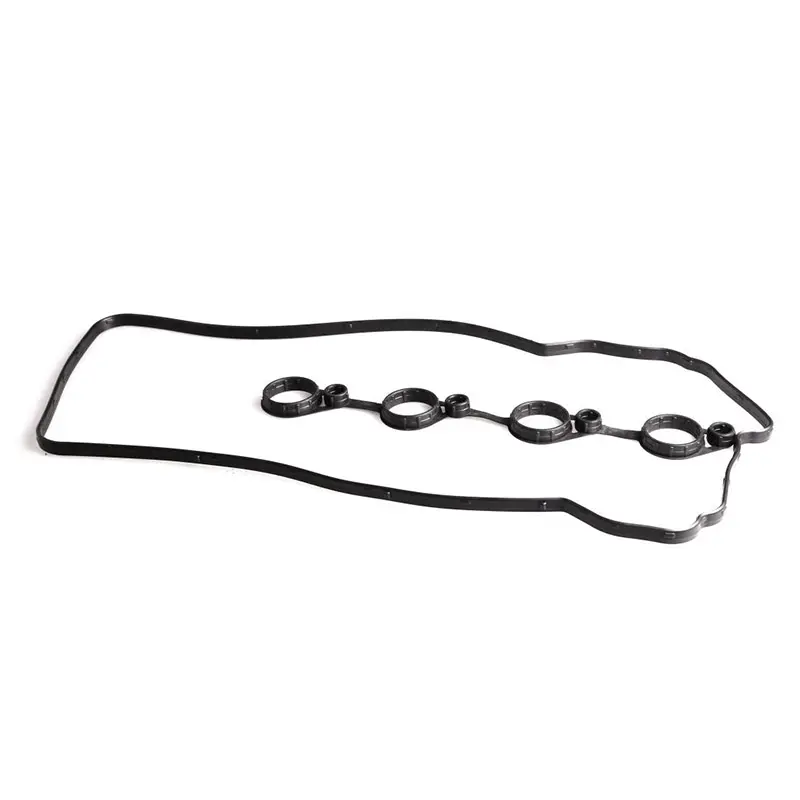

Round gasket rubber products serve as an essential solution in numerous industrial applications, providing the necessary sealing and insulation that certain operations demand. Having spent years exploring the intricacies of material selection and gasket design, I understand the importance of these seals in achieving operational efficiency and safety in varied environments.

Authoritativeness is built through rigorous testing and adherence to industry standards. Round gasket rubbers, to be deemed reliable, must comply with certifications like ASTM or ISO, depending on the application's region and specific demands. These certifications ensure that the gaskets perform under expected conditions, maintaining integrity when subjected to pressure, temperature variations, and chemical exposure. For trustworthiness, procurement from reputable suppliers is key. Suppliers with a long-standing presence in the industry have a track record of delivering high-quality products. They are more likely to invest in continuous improvement processes and provide warranties for their gaskets, reinforcing consumer confidence in their products' reliability. Moreover, there’s an increasing trend in sustainable manufacturing practices. Consumers and businesses alike are now more conscious of environmental impacts, prompting the adoption of eco-friendly materials and processes. Many manufacturers are now adopting green manufacturing practices, ensuring that their round gasket rubber products are not only effective but environmentally responsible. This includes the use of non-toxic additives and recycling programs that reduce waste. In conclusion, round gasket rubber plays a pivotal role across various industries. Its performance is inherently tied to the correct choice of material, adherence to quality standards, and responsible production practices. Empowered with experience, expertise, authority, and trust, engineers and procurement managers can make informed decisions that enhance operational efficiency, safety, and sustainability. For anyone considering these vital components, it is crucial to prioritize a comprehensive understanding of the specific operational requirements to select the most suitable round gasket rubber, thereby maximizing their machinery's performance and lifespan.

Authoritativeness is built through rigorous testing and adherence to industry standards. Round gasket rubbers, to be deemed reliable, must comply with certifications like ASTM or ISO, depending on the application's region and specific demands. These certifications ensure that the gaskets perform under expected conditions, maintaining integrity when subjected to pressure, temperature variations, and chemical exposure. For trustworthiness, procurement from reputable suppliers is key. Suppliers with a long-standing presence in the industry have a track record of delivering high-quality products. They are more likely to invest in continuous improvement processes and provide warranties for their gaskets, reinforcing consumer confidence in their products' reliability. Moreover, there’s an increasing trend in sustainable manufacturing practices. Consumers and businesses alike are now more conscious of environmental impacts, prompting the adoption of eco-friendly materials and processes. Many manufacturers are now adopting green manufacturing practices, ensuring that their round gasket rubber products are not only effective but environmentally responsible. This includes the use of non-toxic additives and recycling programs that reduce waste. In conclusion, round gasket rubber plays a pivotal role across various industries. Its performance is inherently tied to the correct choice of material, adherence to quality standards, and responsible production practices. Empowered with experience, expertise, authority, and trust, engineers and procurement managers can make informed decisions that enhance operational efficiency, safety, and sustainability. For anyone considering these vital components, it is crucial to prioritize a comprehensive understanding of the specific operational requirements to select the most suitable round gasket rubber, thereby maximizing their machinery's performance and lifespan.

Next: