10 月 . 11, 2024 16:13 Back to list

rubber gasket

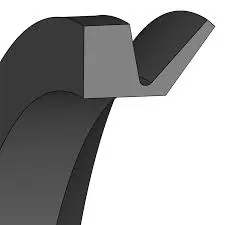

Understanding Rubber Gaskets Importance and Applications

Rubber gaskets are crucial components employed in various mechanical systems, serving as seals to prevent leaks and ensure the integrity of systems containing fluids or gases. They are made from rubber materials that offer excellent flexibility, durability, and resistance to environmental factors, making them suitable for numerous applications.

One of the primary functions of rubber gaskets is to create a barrier between two surfaces, preventing the escape of liquids or gases. This is particularly important in industries such as automotive, aerospace, plumbing, and manufacturing, where leaks can lead to significant operational issues and safety hazards. For instance, in an automobile, rubber gaskets are used to seal the engine components, oil pans, and exhaust systems, ensuring that fluids remain contained even under extreme conditions.

There are various types of rubber used for gaskets, each selected based on the specific needs of the application. Common materials include neoprene, nitrile, EPDM (ethylene propylene diene monomer), and silicone rubber. Each material offers unique properties; for example, EPDM is known for its excellent aging, weathering, and ozone resistance, making it ideal for outdoor applications. Nitrile, on the other hand, is highly resistant to oils and fuels, making it suitable for automotive gaskets.

rubber gasket

In addition to their use in sealing applications, rubber gaskets also play a vital role in vibration dampening

. They can absorb vibrations and reduce noise levels in machinery, which is essential for maintaining operational efficiency and comfort in various settings. This feature is particularly advantageous in the automotive and industrial sectors, where machines and engines generate significant vibrations.The proper installation and maintenance of rubber gaskets are critical to their performance. Over time, gaskets can wear out or degrade due to exposure to heat, pressure, and chemicals. Regular inspections can help detect signs of wear and allow for timely replacements, thereby preventing leaks and prolonging the lifespan of equipment.

In conclusion, rubber gaskets are indispensable elements in modern engineering and manufacturing. Their versatility, durability, and ability to create effective seals make them key to ensuring system efficiency and safety. As technology continues to advance, innovations in materials and manufacturing processes promise even better performance for rubber gaskets in the future. Whether in automotive, aerospace, or industrial applications, understanding and utilizing the right rubber gasket can significantly impact the reliability and efficiency of equipment and systems.