10 月 . 12, 2024 13:19 Back to list

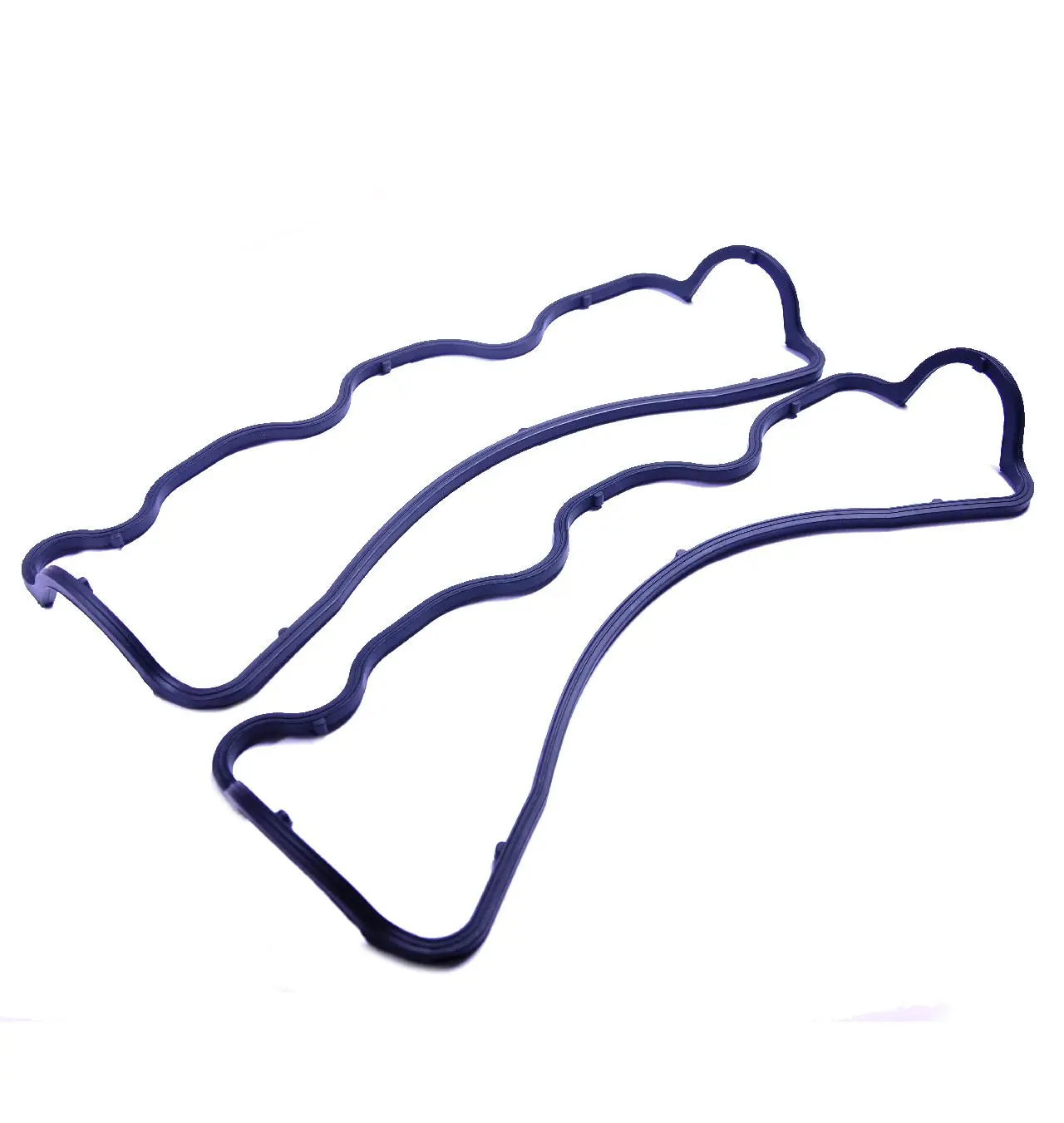

rubber oil seal

Understanding Rubber Oil Seals Essential Components for Industrial Applications

Rubber oil seals are critical components widely used in various industries, including automotive, manufacturing, and machinery. These seals play a vital role in preventing the leakage of oil and other fluids, thus ensuring the efficient operation of machinery and equipment. This article will explore the significance, types, applications, and benefits of rubber oil seals.

Rubber oil seals are designed to fit snugly within mechanisms that require a sealed environment. Their primary function is to retain lubricants while preventing contaminants from entering. This is particularly important in applications where oil loss could result in increased friction, wear, and ultimately equipment failure. By maintaining a proper lubricant level, oil seals contribute to the longevity and reliability of machinery.

One of the most prevalent materials used in manufacturing rubber oil seals is Nitrile Butadiene Rubber (NBR). This synthetic rubber is known for its excellent resistance to oil, fuel, and other chemicals, making it an ideal choice for applications in automotive engines and hydraulic systems. Other materials, such as Fluoroelastomer (Viton) and Silicone, are also used, depending on the specific temperature and chemical resistance requirements of the application.

rubber oil seal

There are different types of rubber oil seals, including lip seals and rotary shaft seals

. Lip seals, characterized by their flexible lip, create a tight seal around rotating shafts, effectively preventing fluid leakage. Rotary shaft seals, on the other hand, are designed to seal around a rotating shaft, often featuring a metal casing that provides structural support and resilience against high-pressure situations.In terms of applications, rubber oil seals are found in a myriad of devices, from cars and motorcycles to industrial machinery and household appliances. In vehicles, they help to ensure that engine oil remains contained, while also preventing dirt and moisture from compromising engine performance. In hydraulic systems, they maintain fluid pressure, which is crucial for the effective operation of hydraulic machinery.

The benefits of using rubber oil seals are manifold. They not only help reduce the risk of fluid leakage but also contribute to the efficient operation of equipment by minimizing friction. By preventing contamination, oil seals enhance the overall performance and durability of machines. Moreover, their cost-effectiveness and ease of installation make them a preferred choice for manufacturers and maintenance professionals alike.

In conclusion, rubber oil seals are indispensable in modern industrial applications. Their ability to retain lubricants and prevent contamination directly impacts the efficiency and longevity of various machinery and equipment. As technology continues to evolve, the development of advanced rubber materials will further enhance the performance of these essential components, ensuring reliability and efficiency across industries.