2 月 . 10, 2025 09:59 Back to list

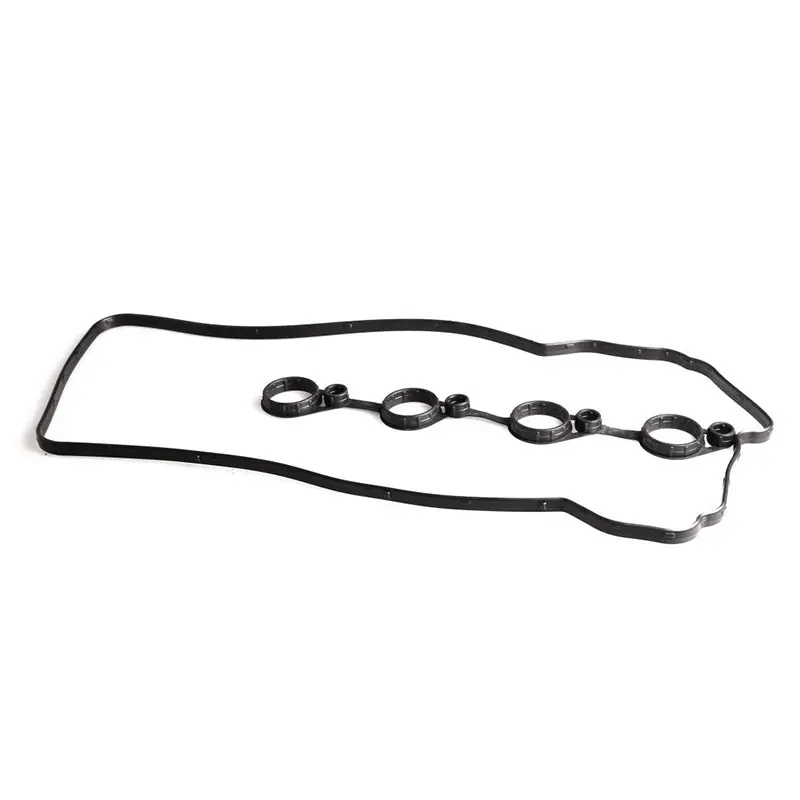

rubber pipe gasket

The world of plumbing and industrial piping is filled with intricate components that ensure the seamless transport and control of fluids. Among these elements, rubber pipe gaskets play an unsung hero's role. As a seasoned professional who has spent years working with these crucial components, I can offer an in-depth exploration of rubber pipe gaskets, emphasizing their importance and usage in various sectors.

Expert knowledge establishes that the installation of these gaskets is just as critical as their selection. Improper installation can lead to catastrophic failures, rendering even the highest-quality gaskets ineffective. Professionals trained in the installation of rubber gaskets ensure that they are seated correctly, without stretching or compressing them beyond their limits. Such expertise not only extends the life of the gasket but also enhances the safety and efficiency of the entire piping system. One cannot overstate the importance of regular maintenance checks. While rubber gaskets are incredibly durable, they aren't immune to wear and tear. Routine inspections can preempt potential failures, especially in high-pressure systems. Developing a thorough maintenance schedule, based on the type of fluid being transported and the operating conditions, is a best practice worth adopting. Our professional authority on rubber pipe gaskets is built upon years of field experience and collaboration with leading engineers and manufacturers. The commitment to continued research into newer materials and designs reflects our dedication to offering solutions that meet modern challenges. As pipelines carry increasingly aggressive and diverse substances, the need for advanced gasket solutions is more pressing than ever. In conclusion, rubber pipe gaskets are critical components that play an essential role in various industrial and residential applications. Their selection, installation, and maintenance demand a professional touch, grounded in extensive empirical and technical knowledge. When approached correctly, they ensure the integrity and efficiency of fluid transport systems. Acknowledging their importance and obtaining them from reputable sources enhances not just the operational capabilities of a system but also fosters a prolonged trust in its uninterrupted service.

Expert knowledge establishes that the installation of these gaskets is just as critical as their selection. Improper installation can lead to catastrophic failures, rendering even the highest-quality gaskets ineffective. Professionals trained in the installation of rubber gaskets ensure that they are seated correctly, without stretching or compressing them beyond their limits. Such expertise not only extends the life of the gasket but also enhances the safety and efficiency of the entire piping system. One cannot overstate the importance of regular maintenance checks. While rubber gaskets are incredibly durable, they aren't immune to wear and tear. Routine inspections can preempt potential failures, especially in high-pressure systems. Developing a thorough maintenance schedule, based on the type of fluid being transported and the operating conditions, is a best practice worth adopting. Our professional authority on rubber pipe gaskets is built upon years of field experience and collaboration with leading engineers and manufacturers. The commitment to continued research into newer materials and designs reflects our dedication to offering solutions that meet modern challenges. As pipelines carry increasingly aggressive and diverse substances, the need for advanced gasket solutions is more pressing than ever. In conclusion, rubber pipe gaskets are critical components that play an essential role in various industrial and residential applications. Their selection, installation, and maintenance demand a professional touch, grounded in extensive empirical and technical knowledge. When approached correctly, they ensure the integrity and efficiency of fluid transport systems. Acknowledging their importance and obtaining them from reputable sources enhances not just the operational capabilities of a system but also fosters a prolonged trust in its uninterrupted service.