9 月 . 06, 2024 11:27 Back to list

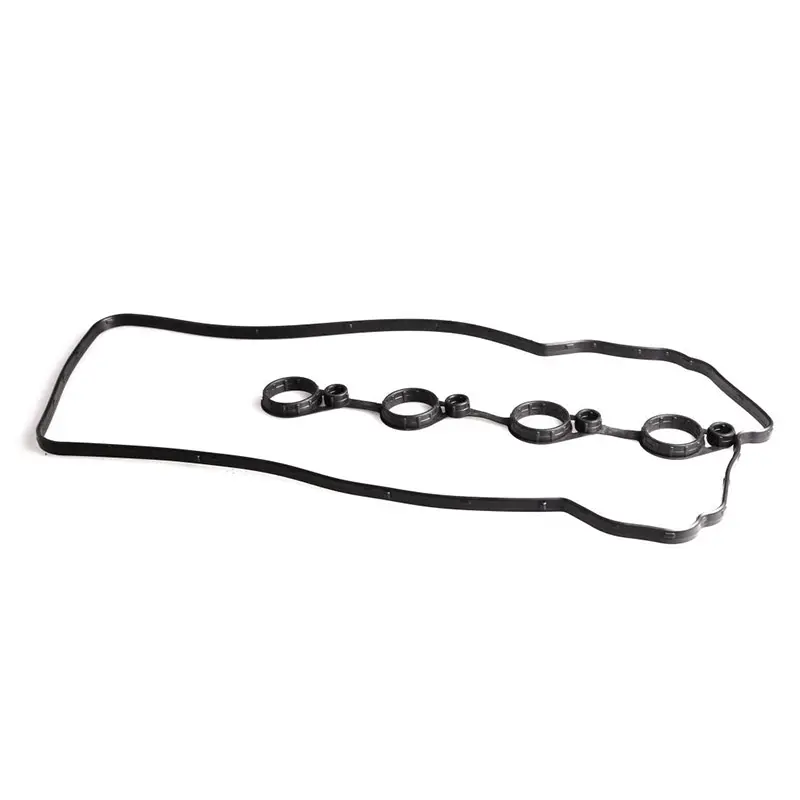

High-Quality Silicone Gasket Sheet – Durable and Versatile Sealing Solutions

Understanding Silicone Gasket Sheets Properties, Applications, and Benefits

Silicone gasket sheets have emerged as a vital component in various industrial applications, owing to their unique properties and versatility. Made from silicone rubber, these sheets possess a soft, flexible nature, which allows them to create effective seals between different surfaces. Silicone, a synthetic polymer, is known for its excellent temperature resistance, durability, and chemical inertness, making silicone gasket sheets suitable for demanding conditions.

One of the most notable features of silicone gasket sheets is their ability to withstand extreme temperatures. They can function effectively in a broad temperature range, usually between -80°F to +450°F (-62°C to +232°C). This thermal stability makes them indispensable in applications where thermal expansion and contraction occur, thus ensuring consistent sealing performance.

Moreover, silicone gasket sheets exhibit remarkable resistance to various chemicals, oils, and greases

. This is particularly important in industries such as automotive, food processing, and pharmaceuticals, where exposure to such substances is common. The inert nature of silicone means it does not react with most chemicals, ensuring the integrity of the seal and preventing contamination, which is crucial in sensitive applications.In addition to their chemical resistance, silicone gasket sheets are also waterproof and withstand ultraviolet (UV) exposure, making them ideal for outdoor applications. Their resilience against environmental factors ensures longevity, reducing the need for frequent replacements and maintenance.

silicone gasket sheet

The manufacturing process of silicone gasket sheets allows for customization in thickness, density, and color. This flexibility enables them to meet specific requirements of various applications and industries. They can be easily cut into custom shapes and sizes based on the needs of the user, providing a tailored solution for sealing and cushioning.

Silicone gasket sheets find application in numerous sectors, including automotive, aerospace, electronics, plumbing, and HVAC systems. In the automotive industry, they are often used for sealing engine components and temperature-sensitive assemblies. In HVAC systems, they help in maintaining airtight seals to enhance energy efficiency. In the food and pharmaceutical industries, their ability to maintain cleanliness and prevent contamination is vital.

Another remarkable advantage of silicone gasket sheets is their ease of installation and maintenance. Their lightweight nature and flexibility allow for swift installation, and because they do not degrade easily over time, they require minimal upkeep.

In conclusion, silicone gasket sheets are an essential component in various industries due to their outstanding properties, including temperature resistance, chemical inertness, and UV stability. Their customizability and ease of installation further enhance their appeal, making them a preferred choice for engineers and manufacturers seeking reliable sealing solutions. As industries continue to evolve, the demand for effective sealing solutions like silicone gasket sheets is likely to grow, highlighting their importance in modern manufacturing and maintenance practices.