10 月 . 04, 2024 21:38 Back to list

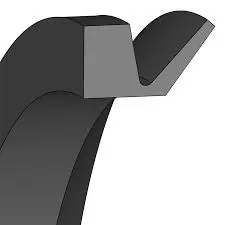

silicone on rubber gasket

Silicone on Rubber Gaskets An Overview

In various applications across industries, the significance of effective sealing solutions cannot be overstated. One prominent example is the use of silicone on rubber gaskets, which combines the advantageous properties of both materials to enhance performance in sealing applications.

Understanding Gaskets

Gaskets are mechanical seals that fill the space between two or more mating surfaces to prevent leakage of fluids or gases. They play a crucial role in machinery, automotive applications, plumbing, and countless other environments where tight seals are required to maintain pressure, avoid contamination, and ensure operational efficiency. Traditionally made from materials like rubber, cork, and metal, gaskets need to withstand various conditions, including temperature fluctuations, chemical exposure, and mechanical stress.

The Role of Silicone

Silicone is a synthetic polymer that is prized in various industries for its flexibility, durability, and resistance to extreme temperatures. It boasts superior weatherability, making it ideal for applications exposed to harsh environmental conditions. Silicone gaskets maintain their integrity across a wide range of temperatures, typically from -60°C to over 230°C (-76°F to 446°F), which is a critical factor for many engineering applications. Moreover, silicone exhibits exceptional resistance to ultraviolet (UV) light, ozone, and certain chemicals, which further extends the lifespan of gaskets made with silicone.

The Combination of Silicone and Rubber

When silicone is applied to rubber gaskets, it creates a composite seal that leverages the strengths of both materials. Rubber gaskets provide fundamental flexibility and cushioning, while silicone enhances the gasket's overall durability and temperature resistance. This combination leads to a gasket that can withstand greater compressive forces without losing its sealing capability.

The silicone layer can be integrated onto rubber gaskets through various methods, including molding or bonding. The end result is a gasket that offers enhanced performance characteristics such as

1. Improved sealing efficiency The silicone surface can better conform to irregularities in mating surfaces, providing a more effective seal. 2. Increased lifespan Silicone's durability against environmental factors contributes to a significantly longer service life compared to standard rubber gaskets.

3. Heat and cold resistance The adaptability of silicone to extreme temperatures makes these gaskets suitable for applications in automotive engines, aerospace, and electronic devices.

silicone on rubber gasket

Application Areas

The use of silicone on rubber gaskets spans numerous fields, including

- Automotive Gaskets in engines, transmissions, and exhaust systems benefit from the heat and chemical resistance provided by silicone.

- Aerospace Silicone rubber gaskets are used in various components where reliability and performance are critical, such as in fuel systems and cabin pressurization.

- Electronics Silicone gaskets are utilized in electrical enclosures and components to prevent moisture ingress and ensure the proper functioning of devices.

- Water Treatment In plumbing and water systems, silicone rubber gaskets can help in providing watertight seals, preventing leaks that could lead to costly damages.

Conclusion

The integration of silicone onto rubber gaskets marks a significant advancement in sealing technology. By leveraging the properties of both materials, engineers and manufacturers can achieve enhanced sealing solutions suited for a wide array of demanding applications. As industries continue to evolve and the need for reliable sealing solutions grows, the application of silicone on rubber gaskets will likely become more prevalent, providing critical benefits in performance, longevity, and efficiency.

In summary, the combination of silicone and rubber in gasket manufacturing presents an innovative solution to many challenges faced in seal applications. As technology progresses, the adaptability and versatility of these advanced gaskets will undoubtedly play a vital role in driving future developments across multiple sectors.