8 月 . 20, 2024 03:49 Back to list

Similar Oil Seal Specifications for Enhanced Performance 25 40 7 Size

Understanding Oil Seal 25 40 7 Importance, Applications, and Maintenance

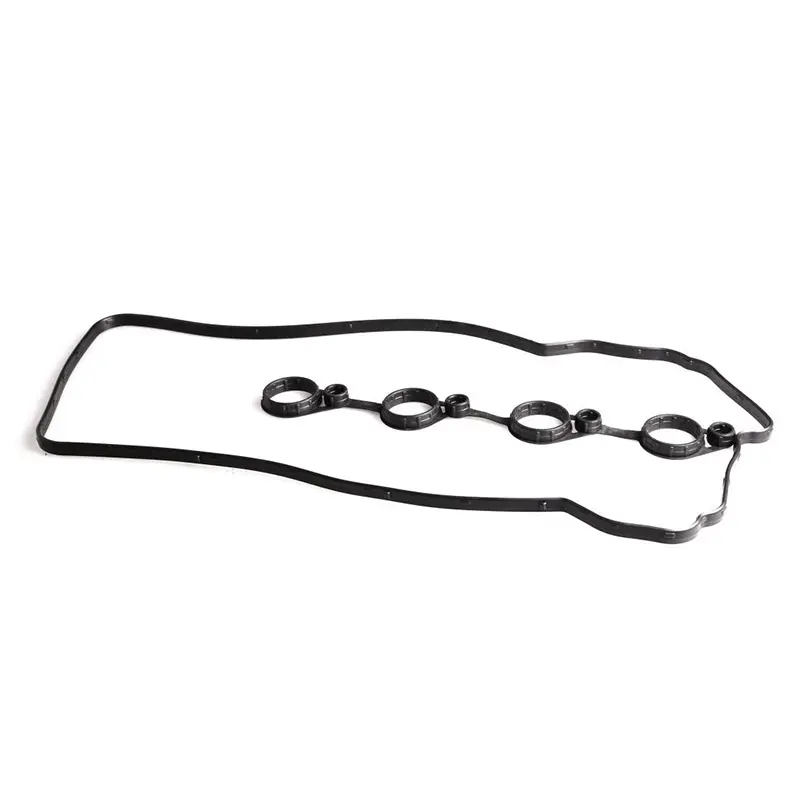

Oil seals are critical components in various mechanical systems, acting as barriers that prevent the leakage of lubricants and the ingress of contaminants. The designation 25 40 7 refers to specific dimensions of an oil seal, indicating a shaft diameter of 25 mm, an outer diameter of 40 mm, and a thickness of 7 mm. These dimensions are crucial in ensuring compatibility with the machinery in which the seal is used.

Importance of Oil Seals

Oil seals play a pivotal role in the longevity and efficiency of machinery. They are essential in sealing rotating shafts, which are found in engines, pumps, gearboxes, and many other applications. Proper sealing ensures that lubricant remains within the system, reducing wear and tear on mechanical components due to friction and heat. Additionally, oil seals prevent the entry of dirt, dust, and moisture, which can lead to premature failure of machinery.

Applications of Oil Seal 25 40 7

The oil seal with dimensions 25 40 7 is utilized in various industrial applications. For instance, it is commonly found in automotive engines, where it seals the crankshaft and camshaft to prevent oil leaks. In hydraulic systems, these seals help maintain pressure and protect hydraulic fluid from contamination. Additionally, this seal design has applications in industrial machinery, such as conveyor systems and factory equipment, where reliability and efficiency are paramount.

oil seal 25 40 7

Each application requires specific properties from the oil seal material, including temperature resistance, chemical compatibility, and durability under high-pressure conditions. Common materials used for oil seals include nitrile rubber (NBR), fluoroelastomer (FKM), and polyurethane, each selected based on the operating environment and media involved.

Maintenance and Replacement

Regular maintenance of machinery often includes checking the integrity of oil seals. Signs of wear, such as oil leaks or visible cracks, indicate that a seal may need replacement. It’s crucial to address these issues promptly to avoid more significant mechanical failures that can result in costly repairs and downtime.

To replace an oil seal, one must carefully remove the old seal without damaging the housing or shaft. Proper installation of the new seal is equally important; it should be done in a clean environment to prevent contaminants from entering the system. The seal must be aligned correctly and installed using appropriate tools to avoid distortion, which could lead to premature failure.

Conclusion

The oil seal 25 40 7 is a small but vital component in various mechanical systems, playing a significant role in maintaining efficiency and preventing damage. Understanding its function, applications, and maintenance procedures is essential for anyone involved in equipment operation or repair. By ensuring the proper use and care of oil seals, industries can enhance the reliability and longevity of their machinery, ultimately saving time and reducing costs associated with maintenance and repairs. Whether used in automotive, industrial, or hydraulic applications, the importance of oil seals cannot be overstated in the pursuit of optimal machine performance.