8 月 . 17, 2024 03:21 Back to list

Similar Specifications for 40x52x7 Oil Seal Replacement Options and Alternatives

Understanding the 40x52x7 Oil Seal Importance and Applications

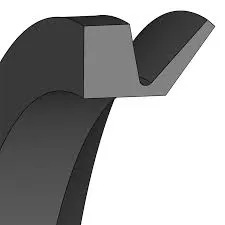

In various mechanical applications, oil seals play a crucial role in ensuring the longevity and efficiency of machinery. Among the many types of oil seals available, the 40x52x7 oil seal is notable for its dimensions and versatility. This article delves into the specifics of the 40x52x7 oil seal, highlighting its features, applications, and the importance of quality in oil seal manufacturing.

What is an Oil Seal?

An oil seal, also known as a rotary shaft seal, is a mechanical device designed to seal the gap between stationary and moving components in a machine. Its primary purpose is to prevent the leakage of lubricants and the intrusion of contaminants. The proper functioning of oil seals is essential to maintain the performance and reliability of machinery, especially in environments where dust, dirt, and moisture can compromise mechanical integrity.

Key Features of the 40x52x7 Oil Seal

The specification 40x52x7 refers to the oil seal's inner diameter (ID), outer diameter (OD), and thickness. In this case

- Inner Diameter (ID) 40 mm - Outer Diameter (OD) 52 mm - Thickness 7 mm

These dimensions make the 40x52x7 oil seal suitable for various applications, providing an effective barrier against oil leaks and contaminant ingress

.Material Composition

Oil seals are typically made from a variety of materials, including rubber, silicone, or polyurethane. The choice of material greatly influences the seal's performance under different conditions such as temperature fluctuations, exposure to chemicals, and pressure variations. High-quality materials ensure that the seal remains elastic and durable over time, reducing the chances of failure.

Applications of the 40x52x7 Oil Seal

40x52x7 oil seal

The 40x52x7 oil seal finds numerous applications across various industries. Some of the common uses include

1. Automotive Industry In vehicles, oil seals are frequently employed around crankshafts, camshafts, and in differentials to ensure that lubricants remain contained while preventing dirt and moisture from entering critical mechanical components.

2. Industrial Machinery Many types of industrial equipment, including pumps, compressors, and gearboxes, utilize oil seals to maintain proper lubrication and avoid costly downtime due to leaks or failures.

3. Agricultural Equipment Tractors and other farming equipment rely on oil seals to operate efficiently, especially in challenging environments where exposure to dust and debris is common.

4. Home Appliances Oil seals are also present in various household appliances, such as refrigerators and washing machines, where they help maintain efficiency and prolong lifespan.

The Importance of Quality

When it comes to oil seals, the importance of quality cannot be overstated. A subpar seal may lead to premature equipment failure, costly repairs, and unexpected downtime. Therefore, it is crucial for manufacturers and operators to source oil seals from reputable suppliers who adhere to strict quality control standards.

Moreover, maintaining the correct installation technique is equally important. An improperly installed seal can lead to misalignment, which increases wear and can ultimately cause failure. Proper training and awareness of best practices are essential for anyone working with machinery that relies on oil seals.

Conclusion

The 40x52x7 oil seal is an integral component in many mechanical systems, providing a reliable solution to prevent leaks and contaminants. Understanding its features, applications, and the importance of quality can help industries make informed choices that enhance operational efficiency and reduce maintenance costs. By investing in high-quality oil seals and ensuring proper installation, businesses can significantly improve their machinery's performance and longevity.