1 月 . 15, 2025 09:52 Back to list

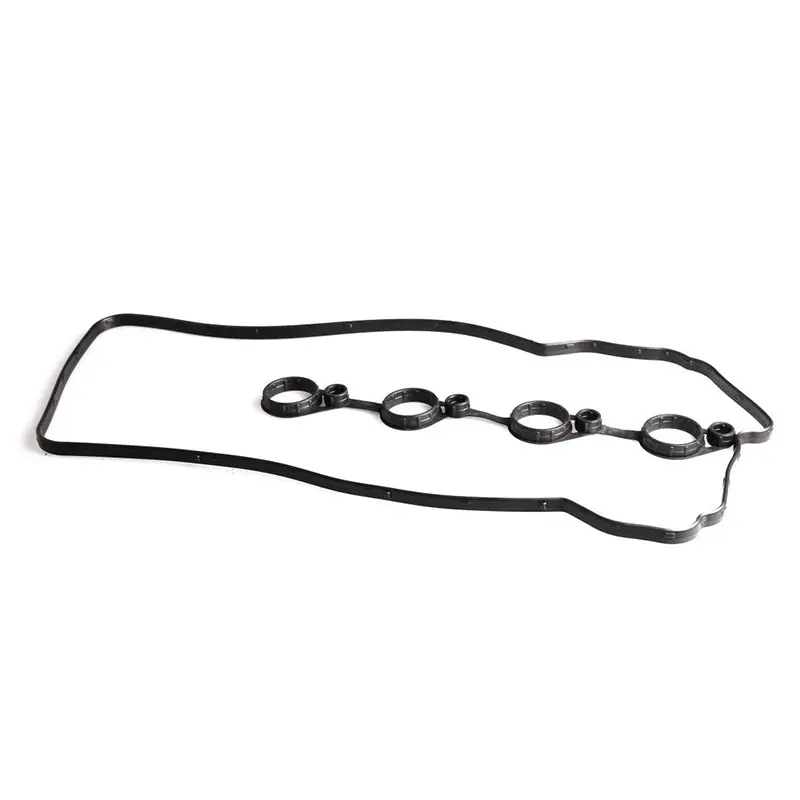

skeleton oil sealing

Skeleton oil seals are crucial components widely recognized in various industrial applications due to their unique design and specialized functionality. Though seemingly simple, their role in enhancing machinery efficiency and ensuring smooth operations is invaluable. This article explores the nuances of skeleton oil seals, shedding light on their importance through a blend of expert insights and real-world experiences.

Skeleton oil seals also find extensive use in harsh environments, where maintaining integrity under extreme conditions is crucial. In automotive applications, they play a vital role in engine performance by ensuring that oil remains within specified compartments, thus maintaining optimal lubrication. In the manufacturing industry, skeleton oil seals are integral to the functionality of hydraulic systems where the need for precision liquid sealing is paramount. Trust in skeleton oil seals stems from their proven track record and the breadth of applications they've been successfully employed in. Their reliability and efficiency are backed by rigorous testing and adherence to industry standards, further cementing their position as a critical component in modern machinery. The continued advancements in material sciences promise even greater performance enhancements, potentially expanding their applicability. Ultimately, the authority and trustworthiness of skeleton oil seals come not just from the advanced technologies that go into their making but also from the tangible benefits experienced by professionals across industries. As machinery and technology evolve, the fundamental need for reliable sealing solutions remains, making skeleton oil seals an ever-relevant choice for engineers and manufacturers looking to achieve superior performance and efficiency. In conclusion, skeleton oil seals are indispensable in maintaining the operational integrity of machinery. Their expert design, coupled with real-world proof of effectiveness, showcases their importance. With ongoing innovation and a commitment to quality, these seals continue to fulfill their critical role in various industrial applications, contributing significantly to technological advancement and operational excellence.

Skeleton oil seals also find extensive use in harsh environments, where maintaining integrity under extreme conditions is crucial. In automotive applications, they play a vital role in engine performance by ensuring that oil remains within specified compartments, thus maintaining optimal lubrication. In the manufacturing industry, skeleton oil seals are integral to the functionality of hydraulic systems where the need for precision liquid sealing is paramount. Trust in skeleton oil seals stems from their proven track record and the breadth of applications they've been successfully employed in. Their reliability and efficiency are backed by rigorous testing and adherence to industry standards, further cementing their position as a critical component in modern machinery. The continued advancements in material sciences promise even greater performance enhancements, potentially expanding their applicability. Ultimately, the authority and trustworthiness of skeleton oil seals come not just from the advanced technologies that go into their making but also from the tangible benefits experienced by professionals across industries. As machinery and technology evolve, the fundamental need for reliable sealing solutions remains, making skeleton oil seals an ever-relevant choice for engineers and manufacturers looking to achieve superior performance and efficiency. In conclusion, skeleton oil seals are indispensable in maintaining the operational integrity of machinery. Their expert design, coupled with real-world proof of effectiveness, showcases their importance. With ongoing innovation and a commitment to quality, these seals continue to fulfill their critical role in various industrial applications, contributing significantly to technological advancement and operational excellence.

Next: