2 月 . 14, 2025 01:07 Back to list

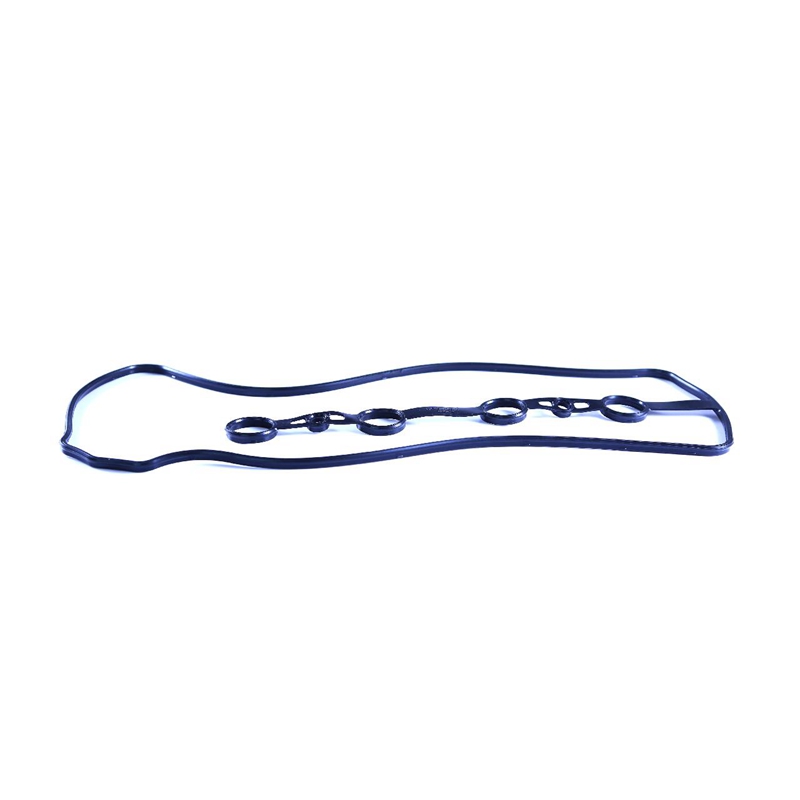

skeleton oil sealing

The realm of industrial sealing technology is vast, and one component that plays a crucial role in ensuring machinery efficiency is the skeleton oil seal. With industries increasingly advancing towards higher precision and reliability, understanding the essentials of skeleton oil seals becomes indispensable to both engineers and business operators. These components might be small, but they hold a significant amount of responsibility in maintaining the integrity of systems under operation. Their high demand across various sectors, such as automotive, marine, and industrial machinery, highlights their undeniable importance.

The reliability of skeleton oil seals is paramount, and their performance is often enhanced through regular monitoring and maintenance. Installation precision cannot be overstated—improper fitting can lead to detrimental failures, resulting in costly downtime and repairs. Ensuring seals are regularly inspected and replaced when necessary can lead to significant savings and enhance the operational efficiency of the entire machinery. Trusting experts for inspection or utilizing the latest monitoring technologies can assist in identifying early signs of wear or damage. Looking forward, innovation continues to drive the evolution of skeleton oil seals. With a growing emphasis on sustainability, manufacturers are exploring eco-friendly materials and processes to reduce the environmental impact of these components. Additionally, smart seals embedded with sensors to monitor real-time data represent the forefront of technological advancement, offering unprecedented insights into machinery health and preemptively addressing potential failures. In conclusion, skeleton oil seals may be a small part of a bigger system, but their impact is profoundly significant. Industries that rely on rotary machinery must prioritize their choice of seals, integrating products that promise performance and reliability. By fostering partnerships with reputable manufacturers that provide expert guidance and support, businesses can ensure that their operations are safeguarded against potential disruptions. The future of skeleton oil sealing certainly looks promising, with advancements that not only aim to enhance efficiency but also align with the global goals of sustainability and technological progression.

The reliability of skeleton oil seals is paramount, and their performance is often enhanced through regular monitoring and maintenance. Installation precision cannot be overstated—improper fitting can lead to detrimental failures, resulting in costly downtime and repairs. Ensuring seals are regularly inspected and replaced when necessary can lead to significant savings and enhance the operational efficiency of the entire machinery. Trusting experts for inspection or utilizing the latest monitoring technologies can assist in identifying early signs of wear or damage. Looking forward, innovation continues to drive the evolution of skeleton oil seals. With a growing emphasis on sustainability, manufacturers are exploring eco-friendly materials and processes to reduce the environmental impact of these components. Additionally, smart seals embedded with sensors to monitor real-time data represent the forefront of technological advancement, offering unprecedented insights into machinery health and preemptively addressing potential failures. In conclusion, skeleton oil seals may be a small part of a bigger system, but their impact is profoundly significant. Industries that rely on rotary machinery must prioritize their choice of seals, integrating products that promise performance and reliability. By fostering partnerships with reputable manufacturers that provide expert guidance and support, businesses can ensure that their operations are safeguarded against potential disruptions. The future of skeleton oil sealing certainly looks promising, with advancements that not only aim to enhance efficiency but also align with the global goals of sustainability and technological progression.

Next: