11 月 . 02, 2024 11:30 Back to list

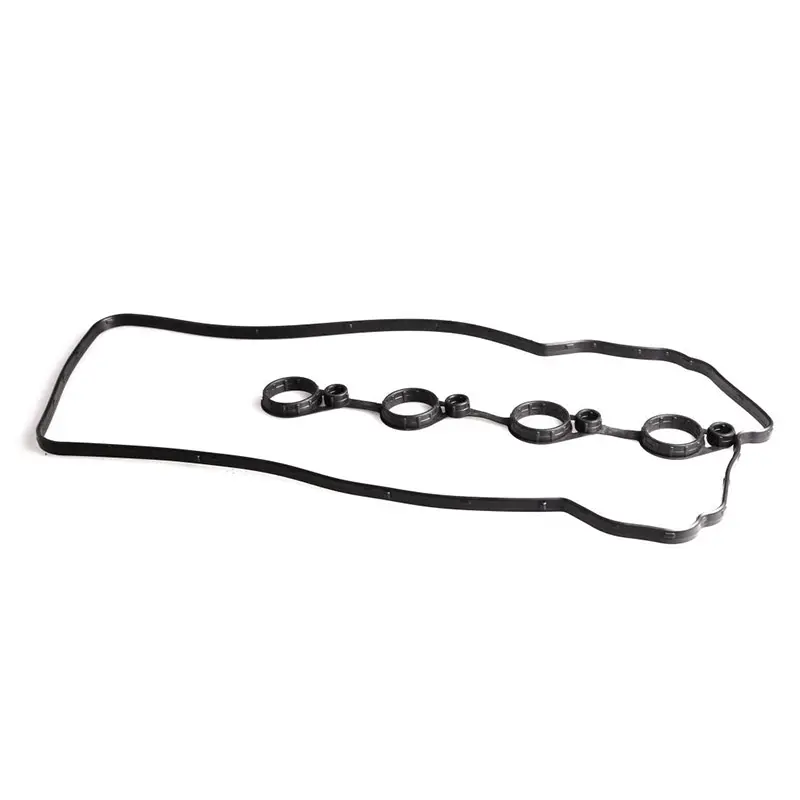

square rubber gasket

The Importance of Square Rubber Gaskets in Modern Applications

In various industrial and domestic applications, gaskets play a crucial role in ensuring the integrity of seals and preventing leaks. One type of gasket that has been gaining attention for its versatility and reliability is the square rubber gasket. With its unique shape and material properties, the square rubber gasket is becoming a staple in many sectors, including manufacturing, automotive, plumbing, and electronics.

What are Square Rubber Gaskets?

Square rubber gaskets are flat seals made from flexible rubber material, typically featuring a square shape. This distinctive design allows for a larger contact area compared to traditional round gaskets, making them ideal for applications where a tight seal is essential. The square shape also means they can fit into corners and edges of machinery and containers more efficiently, reducing the chances of leaks and ensuring a better overall fit.

Material Composition

Square rubber gaskets can be made from various types of rubber materials, including neoprene, EPDM (ethylene propylene diene monomer), silicone, and nitrile rubber. Each material offers different advantages, such as weather resistance, oil resistance, and high-temperature tolerance. The selection of the rubber material is often based on the specific application requirements, such as exposure to chemicals, temperature extremes, and mechanical stresses. For instance, silicone rubber may be preferable in high-temperature applications, while nitrile rubber is typically favored for oil-resistant applications.

Applications of Square Rubber Gaskets

square rubber gasket

The applications for square rubber gaskets are vast and varied

. In the automotive industry, they are commonly used in engine components, oil pans, and transmission housings to prevent fluid leaks and maintain operational efficiency. In plumbing, square rubber gaskets often seal pipe joints, fittings, and valves, ensuring a leak-free environment that is essential for both residential and commercial plumbing systems.In electronics, square rubber gaskets provide essential sealing for connectors and enclosures, protecting sensitive components from dust, moisture, and other environmental hazards. Their ability to withstand harsh conditions makes them invaluable in outdoor and industrial settings, where equipment is subjected to extreme environments.

Advantages of Using Square Rubber Gaskets

One of the foremost advantages of square rubber gaskets is their adaptability. They can easily be manufactured in various sizes and thicknesses to meet specific application requirements. Additionally, their enhanced sealing capability can lead to improved efficiency and durability of the equipment in which they are used.

Furthermore, square rubber gaskets are typically easier to install compared to other gasket shapes. The uniform edges allow for straightforward alignment and placement, reducing the risk of installation errors and subsequent leaks. This ease of installation is particularly beneficial in time-sensitive applications, where efficiency is key.

Conclusion

In summary, square rubber gaskets represent a crucial component across multiple industries. Their unique shape, combined with the variety of rubber materials available, makes them versatile and effective in providing reliable seals. As industries continue to evolve, the demand for innovative sealing solutions like square rubber gaskets will only grow, highlighting the importance of these seemingly simple yet vital components in modern machinery and systems. Whether in automotive, plumbing, or electronics, square rubber gaskets undoubtedly enhance performance and reliability, making them a valuable asset in many applications.