10 月 . 31, 2024 22:47 Back to list

Benefits of Using Synthetic Rubber Gaskets in Industrial Applications for Enhanced Sealing Performance

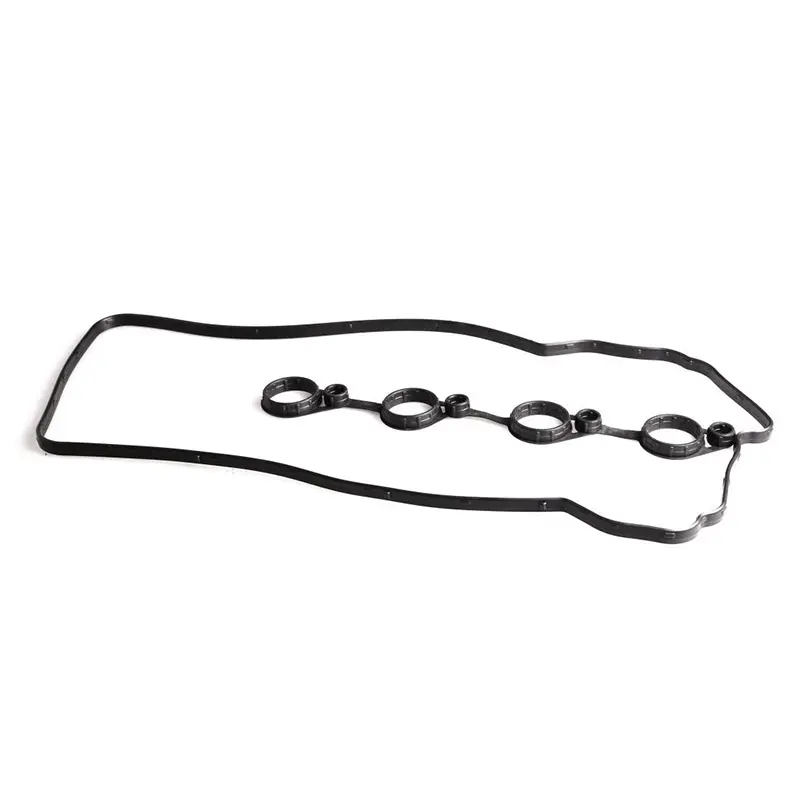

Synthetic Rubber Gaskets A Versatile Solution for Sealing Applications

In the realm of industrial applications, gaskets play a crucial role in ensuring the integrity of various assemblies by preventing leaks and maintaining pressure. Among the diverse materials utilized for manufacturing gaskets, synthetic rubber has emerged as a prominent choice due to its unique properties and versatility. This article explores the advantages and applications of synthetic rubber gaskets, highlighting their significance in various industries.

Synthetic rubber gaskets are made from various types of engineered polymers, including neoprene, EPDM (ethylene propylene diene monomer), and Nitrile (Buna-N). These materials are designed to withstand a wide range of temperatures, pressures, and chemical exposures. The flexibility of synthetic rubbers allows them to create tight seals, even on irregular surfaces, which is essential for applications where precision is critical.

One of the most notable advantages of synthetic rubber gaskets is their resistance to environmental factors. These gaskets can endure harsh conditions such as extreme temperatures, ultraviolet (UV) radiation, and ozone exposure, making them suitable for both indoor and outdoor applications. For example, EPDM gaskets excel in outdoor settings due to their excellent UV and ozone resistance, making them ideal for automotive and building applications.

synthetic rubber gasket

In addition to environmental resistance, synthetic rubber gaskets offer remarkable chemical compatibility

. They can withstand exposure to a wide variety of chemicals, oils, and fuels, which is particularly important in the automotive and chemical processing industries. Nitrile gaskets, for example, are specifically designed for applications involving petroleum-based products, making them indispensable in manufacturing and maintenance sectors.The manufacturing process of synthetic rubber gaskets is another factor that contributes to their popularity. With advancements in production technology, companies can now produce gaskets in various shapes and sizes to meet specific requirements. Customization options allow businesses to create tailored solutions that fit their needs precisely, thus ensuring optimal performance.

Moreover, the cost-effectiveness of synthetic rubber gaskets makes them a practical choice for manufacturers. Compared to traditional materials like cork or metal, synthetic rubber offers a more economical solution without compromising performance. This affordability, combined with their durability and low maintenance needs, makes them an attractive option for long-term use.

In conclusion, synthetic rubber gaskets are a vital component across multiple industries, offering reliable sealing solutions that enhance performance and efficiency. Their exceptional resistance to environmental and chemical factors, coupled with easy customization and cost-effectiveness, positions them as the material of choice for many applications. As industries continue to evolve, the demand for innovative sealing solutions is expected to grow, solidifying the role of synthetic rubber gaskets in modern manufacturing and maintenance practices.