4 月 . 12, 2024 14:24 Back to list

The Ultimate Guide to Oil Seals

Oil seals are found in a wide range of applications, in virtually every industrial sector. It is essential to select the correct oil seal so that the application in which it is used can run efficiently, free of leaks or other issues. In this blog, we explain which factors you should pay attention to when selecting the best oil seal for your application.

Oil seal specifications

The group of oil seals used in dynamic applications include radial shaft seals that seal a rotating shaft around its circumference. They are also known as lip seals, but in this blog we will use the term oil seals.

Usually, these oil seals are used to seal lubricating oil or grease and contain it within the application, so that moving parts such as bearings are continually supplied with enough lubrication. However, such seals are also used for sealing other liquids, gases, and solids, such as powders or granules.

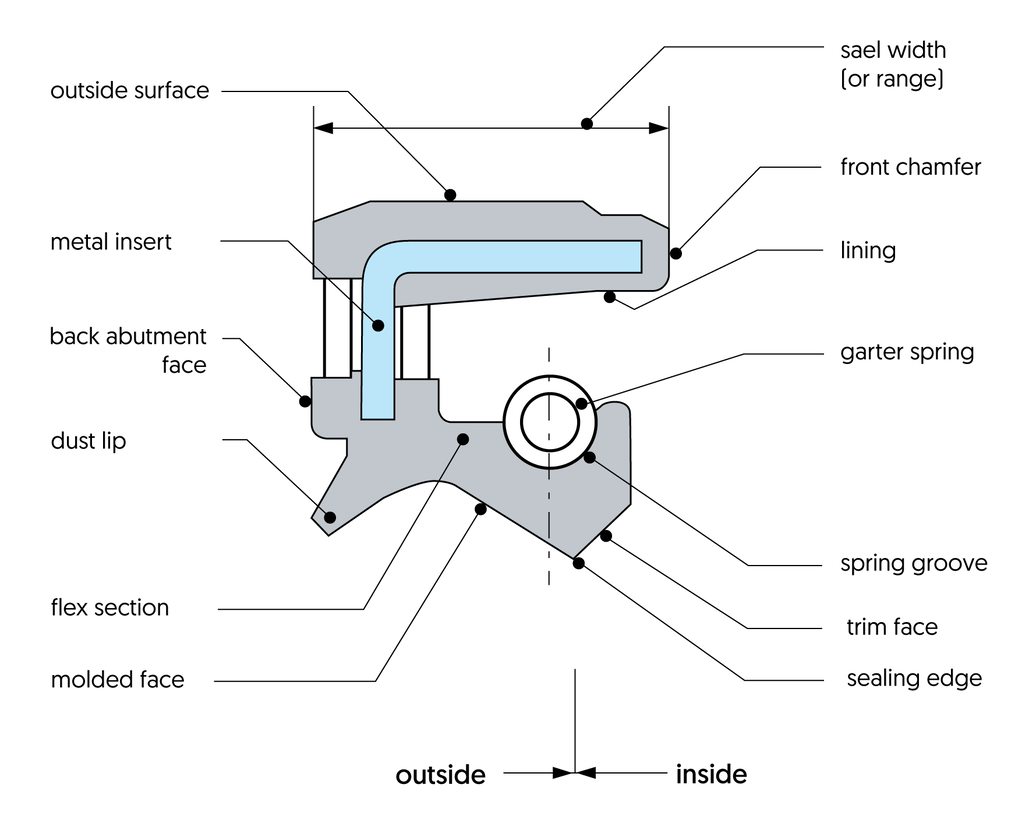

An oil seal consists of:

- An outer case, a body made of metal or provided with a rubber layer

- A rubber or PTFE sealing lip

- A spring, the composition of which depends on the type

The lip is specially designed to ensure the oil seal works effectively with the different forces that arise during rotation. Many different designs and materials are used, so countless types of oil seals are available. These are chosen according to the application; pumps, gearboxes, wheels, and many other rotating applications where fluids need to be sealed. They are used in a variety of sectors, such as the chemical industry, manufacturing, wind turbines, automotive sector, food industry, and more. Oil seals are used in nearly all sectors.

Choosing the right oil seal

What should you take into account when selecting an oil seal? Different types of oil seals and various types of materials are available, each designed for specific uses. It is also important to select the right size of oil seal for the best results. For this reason, selecting the right oil seal requires adequate understanding of the application in which it will be used.

Oil seal type or shape

Most standard oil seals have to comply with the DIN 3760 and ISO 6194 standards. Different standard types of oil seals are available that comply with these requirements.

The most common oil seals are the ERIKS types R, RST, M and MST, which correspond respectively to types A, AS, B and BS according to DIN 3760/ISO 6194.

DIN

Standard 3760/3761

ERIKS

A

Rubber covered

R

AS

As type A with dust lip

RS

B

Metal cased design

M

BS

As type B with dust lip

MS

C

Double metal cased

GV

CS

As type C with dust lip

GVST

All are fitted with a spring to preload the sealing lip. All these types are for non-pressurised or low-pressure applications up to 0.5 bar for diameters of a limited size. For diameter of 500 mm or more, the maximum pressure is 0.1 bar. For higher pressures, special types or PTFE lip seals can be used.

ERIKS type M (type B according to the DIN standard) has a single metal casing and rubber sealing lip. Since the casing is made of metal, it must be fitted in a well-finished, undamaged groove. Large volumes of oil seals with metal casings are often cheaper, which is why they are often used as original equipment in machines. However, if an oil seal has to be replaced, types with a rubber exterior (type R or RST) are easier to fit. Type MST is similar to M and commonly used. The difference is the dust lip in the MST oil seal that prevents dust and dirt reaching the sealing lip, and extends its service life in dusty environments.

ERIKS type GV (type C according to DIN) is equivalent to type M, but is a heavy-duty version with a double metal casing. This can be a useful solution with larger diameters in more demanding applications. There is also a version of this type with a dust lip; the GVST (type CS according to DIN).

ERIKS type R (type A according to the DIN standard) is identical in shape to type M, but has a rubber outer case with metal reinforcement on the inside. The rubber creates a good seal in the housing, even if the housing has suffered minor damage or is not in its best condition for other reasons. The RST version has a dust lip. These types are often chosen to replace a type with a metal outer case because they are easier to install and can cope with minor damage to the groove, such as scratches.

ERIKS also supplies the types GR and GRST. These are virtually identical to the types R and RST, except in this case the metal inner ring is also completely encased in rubber. ERIKS uses FKM rubber here as standard, so these seals are ideal for use in acidic environments.

An overview of the different standard types of oil seals and their main characteristics is shown below.