9 月 . 06, 2024 09:36 Back to list

Valve Cover Gasket Material - High-Performance Solutions for Engine Sealing

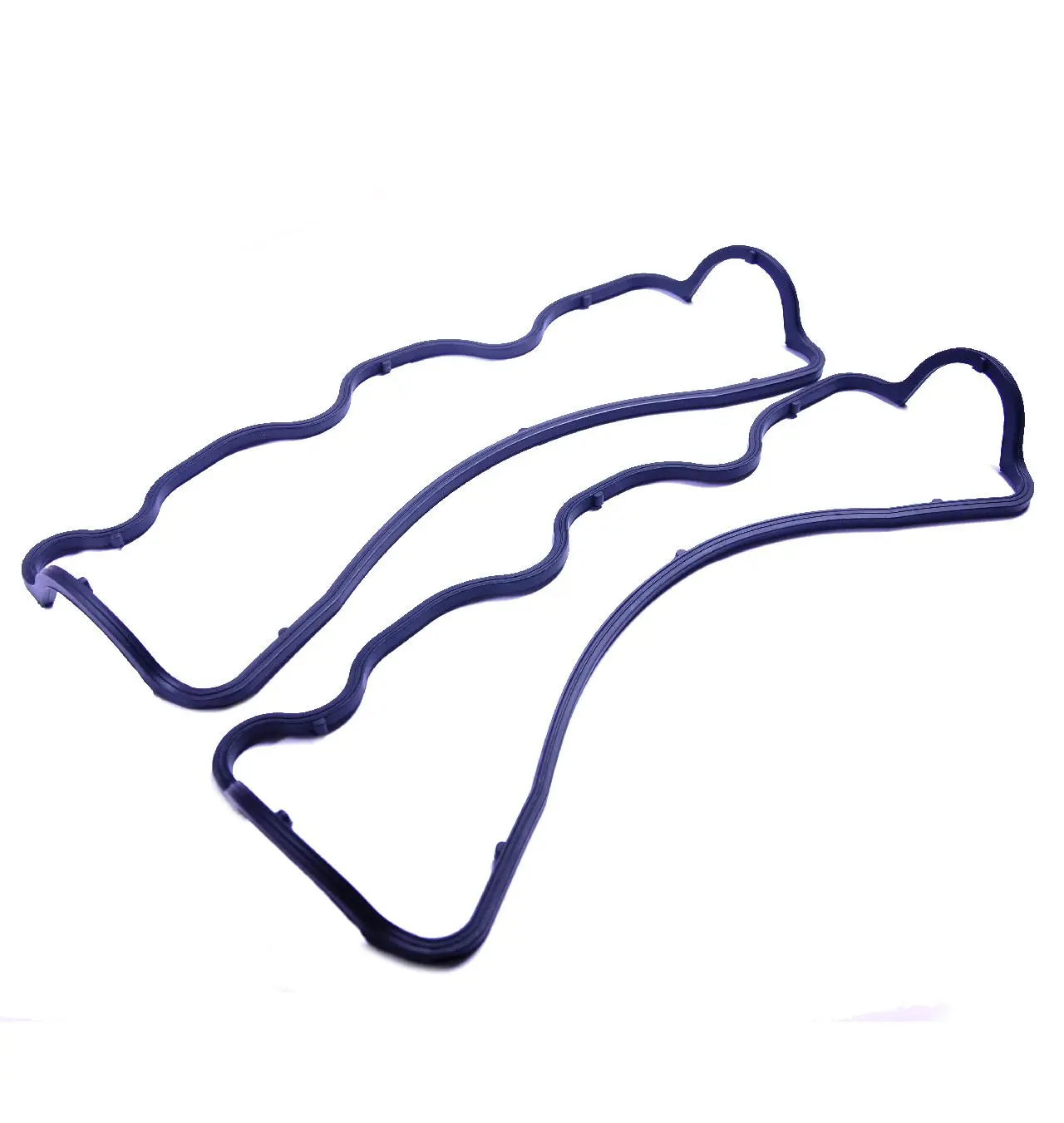

Valve Cover Gasket Material An Essential Component for Engine Performance

The valve cover gasket is a crucial component in any internal combustion engine. Positioned between the valve cover and the cylinder head, this gasket serves to seal the engine's upper section, preventing oil leaks and maintaining the proper pressure in the engine. The material used for valve cover gaskets can significantly impact both engine performance and longevity, making it essential to understand the various materials available.

Traditionally, valve cover gaskets have been made from materials such as cork and rubber. Cork is favored for its traditional reliability and ability to conform to uneven surfaces, providing an effective seal. However, cork can degrade over time, especially in the presence of high temperatures and chemicals. This degradation can lead to leaks, which affect the engine's performance and could ultimately result in more severe issues if left unaddressed.

Rubber, particularly the synthetic variety, has become increasingly popular due to its resistance to heat, oil, and other engine fluids. Materials like nitrile rubber or silicone rubber are commonly used, offering excellent sealing capabilities. Silicone, in particular, has gained a reputation for its durability and flexibility, allowing it to withstand extreme temperature fluctuations while maintaining a strong seal. As such, many modern engines utilize silicone gaskets, ensuring a long-lasting solution for valve cover sealing.

valve cover gasket material

Another emerging trend in valve cover gasket materials is the use of multi-layer steel (MLS) gaskets. This type of gasket combines layers of steel with rubber or silicone coatings, providing a robust and resilient sealing solution. The MLS design allows for better compression distribution, which helps maintain an effective seal over time. This is particularly beneficial for high-performance engines that operate under more demanding conditions.

When selecting a valve cover gasket, it is important to consider the engine's specific requirements and the operating environment. High-performance engines may require gaskets made from more advanced materials to withstand higher temperatures and pressures. Conversely, standard engines may function effectively with traditional cork or rubber gaskets.

In conclusion, valve cover gasket materials play a vital role in ensuring an engine's efficient operation. With advancements in materials science, options such as silicone and multi-layer steel gaskets provide superior sealing capabilities and durability. Understanding these materials can help vehicle owners make informed decisions, ultimately enhancing engine performance and longevity. Regular inspection and timely replacement of valve cover gaskets are essential steps in engine maintenance, ensuring optimal functionality over the lifetime of the vehicle.