10 月 . 11, 2024 07:03 Back to list

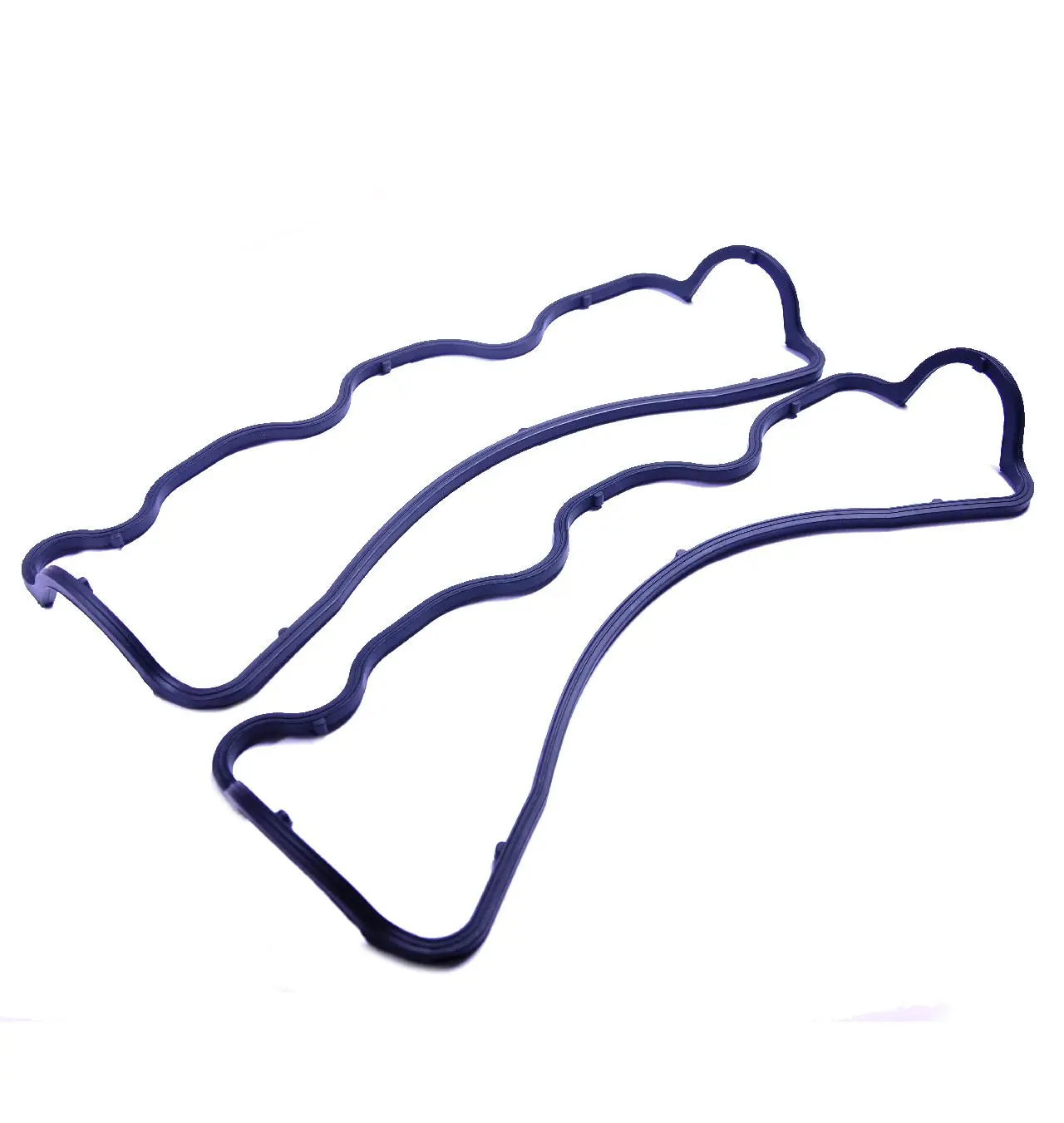

white rubber gasket

The Importance of White Rubber Gaskets in Various Applications

White rubber gaskets play a crucial role in numerous industrial and commercial applications, thanks to their unique properties and versatility. Designed primarily to create a seal between two surfaces, these gaskets are essential in preventing leaks, maintaining pressure, and protecting components from environmental factors. Made from synthetic or natural rubber, white rubber gaskets are particularly favored for their resistance to various chemicals, temperature fluctuations, and wear.

One of the key features of white rubber gaskets is their excellent chemical resistance. This makes them ideal for use in industries such as food processing, pharmaceuticals, and chemical manufacturing. In these settings, the need for sanitary conditions is paramount. White rubber gaskets can be easily cleaned and are less likely to harbor bacteria or other contaminants, ensuring compliance with health and safety regulations.

In addition to their chemical resilience, white rubber gaskets are also highly adaptable

. They can be manufactured in various shapes and sizes to fit different equipment and machinery. Whether used in pumps, valves, or piping systems, these gaskets can be tailored to meet specific requirements. This versatility extends to their application in high-performance environments, where they can withstand extreme temperatures, pressures, and mechanical stresses.white rubber gasket

Moreover, the visual appeal of white rubber gaskets cannot be overlooked. Their clean, bright appearance is often preferred in industries where aesthetics are important. For example, in food processing and pharmaceuticals, a clean and hygienic setup is crucial not only for safety but also for brand representation. The use of white rubber gaskets helps create a professional and clean image, building trust with consumers and clients.

Another significant advantage of white rubber gaskets is their ability to provide an effective seal without the need for adhesives or additional sealing agents. This feature simplifies assembly processes and reduces the risk of contamination during installation. Furthermore, white rubber gaskets are durable and can last for extended periods, minimizing the need for frequent replacements and lowering maintenance costs.

In conclusion, white rubber gaskets are indispensable components across many industries. Their chemical resistance, adaptability, aesthetic appeal, and ease of use make them the preferred choice for a wide range of applications. As industries continue to prioritize safety, efficiency, and cleanliness, the demand for high-quality white rubber gaskets is likely to grow even further, underscoring their importance in modern manufacturing and processing environments.